- Home

- »

- Distribution & Utilities

- »

-

Vertical Lift Module Market Size, Share, Growth Report, 2030GVR Report cover

![Vertical Lift Module Market Size, Share & Trends Report]()

Vertical Lift Module Market (2024 - 2030) Size, Share & Trends Analysis Report By Delivery Type (Single Level Delivery, Dual Level Delivery), By Storage Type, By End-use (Automotive, Metals & Machinery), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-341-7

- Number of Report Pages: 152

- Format: PDF

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Energy & Power

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Vertical Lift Module Market Summary

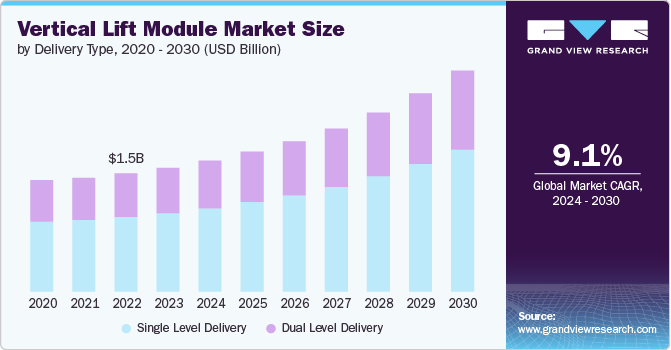

The global vertical lift module market size was estimated at USD 1,558.9 million in 2023 and is anticipated to reach USD 2,783.8 million by 2030, growing at a CAGR of 9.1% from 2024 to 2030. The market is experiencing significant growth due to the increasing demand for automated storage and retrieval systems (ASRS) across multiple sectors.

Key Market Trends & Insights

- Asia Pacific dominated the vertical lift module market with a revenue share of 46.9% in 2023.

- China to witness fastest market growth at 9.9% CAGR over the forecast period.

- By delivery type, the single level segment led the market and accounted for 63.4% of the global revenue share in 2023.

- By storage type, the non-refrigerated type segment accounted for 56.1% of the global revenue share in 2023.

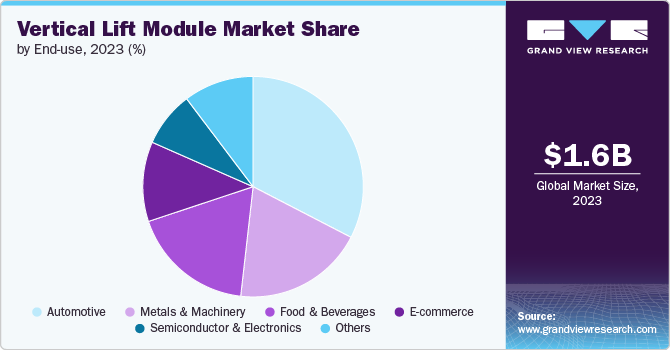

- By end use, the automotive segment accounted for 32.6% of the global vertical lift module market revenue share in 2023.

Market Size & Forecast

- 2023 Market Size: USD 1,558.9 Million

- 2030 Projected Market Size: USD 2,783.8 Million

- CAGR (2024-2030): 9.1%

- Asia Pacific: Largest market in 2023

VLMs are an integral part of modern warehousing, logistics, and distribution centers, offering efficient storage solutions that save floor space, reduce worker fatigue, and improve inventory management through automated controls. Moreover, manufacturers are seeking ways to optimize their storage spaces. vertical lift module significantly reduces the footprint of storage areas by utilizing vertical space, which is particularly beneficial in urban areas where space comes at a premium. By automating the storage and retrieval process, vertical lift module reduces the need for manual labor, thereby decreasing the risk of workplace injuries and improving overall efficiency.

Furthermore, the surge in online shopping necessitates more efficient warehousing and distribution strategies where VLMs play a critical role by saving space and speeding up the retrieval process. There's a push within the U.S. manufacturing sector towards Industry 4.0 integrating digital technologies into manufacturing operations. VLMs enhance storage density and efficiency, aligning with the goals of modern, lean manufacturing practices.

Drivers, Opportunities & Restraints

The vertical lift module market is driven by several factors, including the increasing adoption of automated storage solutions, the need for space optimization in warehouses and manufacturing facilities, and the growing emphasis on workplace safety and efficiency. Vertical lift modules offer automated storage and retrieval features that significantly cut down the time workers spend searching for items. This boosts operational efficiency and productivity, as goods can be retrieved quickly and accurately.

Industries across the globe are grappling with labor shortages, and VLMs present a viable solution by automating tasks that would otherwise require manual labor. Moreover, by automating the retrieval process, vertical lift modules minimize the risk of workplace injuries associated with lifting and carrying goods. With integrated inventory management software, VLMs provide real-time tracking of items, improving inventory accuracy and reducing the likelihood of stockouts or overstock. This precision is crucial for industries where inventory management directly impacts service levels and profitability.

While the outlook is generally positive, challenges such as the initial high capital investment for VLM installation and the need for technical expertise for operation and maintenance could moderate market growth. However, the long-term ROI and operational efficiencies offered by VLMs often outweigh these challenges.

Delivery Type Insights

“The demand for single level vertical lift module delivery type segment is expected to grow at a significant CAGR of 9.3% from 2024 to 2030 in terms of revenue”

The single level delivery type segment led the market and accounted for 63.4% of the global revenue share in 2023. The adoption of single level vertical lift modules is driven by the need for efficient use of space, improved worker safety and ergonomics, increased inventory management accuracy, and the requirement for fast and efficient retrieval processes. Single level VLMs are particularly popular in industries where space is at a premium or where fast, single-item retrieval is a frequent requirement. This includes retail, e-commerce, pharmaceuticals, electronics, and automotive parts.

The dual-level Vertical Lift Module (VLM) delivery type represents a sophisticated segment within the automated storage and retrieval systems market, catering to businesses looking to maximize efficiency and throughput within their warehousing and distribution processes. These systems can be customized to fit various types of inventories and are adaptable to changing business needs. Shelves within the VLMs can be reconfigured to accommodate different item sizes, and the system software can be updated to optimize storage density and retrieval strategies.

Storage Type Insights

“The demand for non-refrigerated storage type segment is expected to grow at a significant CAGR of 9.2% from 2024 to 2030 in terms of revenue”

The non-refrigerated type segment accounted for 56.1% of the global revenue share in 2023. Non-refrigerated vertical lift module utilize vertical space to maximize storage capacity within a minimal footprint. This is particularly beneficial in urban warehouses or facilities with limited floor space. With integrated inventory management software, non-refrigerated VLMs enable real-time tracking and management of inventory. The application of non-refrigerated VLMs spans across various industries such as manufacturing, automotive, electronics, retail, and warehousing, among others, offering efficient, space-saving, and automated storage solutions.

The refrigerated vertical lift module type caters to industries requiring precise temperature-controlled environments for the storage and handling of their products. These specialized VLMs integrate refrigeration or climate control systems within the automated storage and retrieval solutions, ensuring that temperature-sensitive goods such as pharmaceuticals, food and beverages, chemicals, and certain electronics are stored under optimal conditions to maintain their integrity, quality, and compliance with regulatory standards. These systems come equipped with advanced inventory management software that allows for real-time tracking, and expiration date monitoring, and ensures a high degree of accuracy in order fulfillment, which is crucial in industries like pharmaceuticals and food service.

End-use Insights

“The demand form E-commerce end use segment is expected to grow at a significant CAGR of 10.1% from 2024 to 2030 in terms of revenue”

The automotive end use segment accounted for 32.6% of the global vertical lift module market revenue share in 2023. The increasing adoption of automated storage solutions in automotive manufacturing and spare parts management is driving the demand for vertical lift modules. VLMs optimize space usage and improve efficiency in managing a vast array of parts, from small screws to larger components. The precise inventory control offered by VLMs helps automotive manufacturers and repair shops reduce retrieval times and minimize errors, leading to improved production workflows and customer service.

The vertical lift modules market for E-commerce end use has been experiencing steady growth, driven by efficient handling of a wide variety of stock-keeping units (SKUs) and fast order picking. VLMs significantly reduce the space needed for inventory storage and enable rapid access to products, enhancing order fulfillment speed and accuracy, which are vital factors for customer satisfaction in the competitive e-commerce landscape. It also allows for scalable storage solutions that can adjust to varying demand levels, improving overall operational efficiency and reducing costs.

Regional Insights

“China to witness fastest market growth at 9.9% CAGR”

The vertical lift module market in Asia Pacific is witnessing significant growth, driven by the region's growing focus on enhancing operational efficiency, inventory management, and space utilization in warehousing and manufacturing sectors. The rapid growth of e-commerce, automotive, electronics, and pharmaceutical industries in countries like China, India, Japan, South Korea, and Southeast Asian nations is fueling the demand for automated storage and retrieval systems (ASRS), including VLMs. Moreover, the e-commerce sector in Asia Pacific is booming, driven by increasing internet penetration, a growing middle class, and a shift in consumer purchasing behavior. E-commerce businesses require efficient and accurate order fulfillment operations, where VLMs can significantly enhance efficiency and storage density

The vertical lift module market in China is estimated to grow at a significant CAGR of 9.9% over the forecast period. China's vast manufacturing sector, which ranges from electronics, automotive, machinery to consumer goods, requires efficient storage and retrieval solutions to manage parts and finished products. VLMs offer a significant advantage in optimizing space and streamlining operations, driving their adoption in manufacturing facilities. Further, as companies continue to seek solutions for improving operational efficiency and reducing costs, the demand for VLMs in China is expected to grow at a substantial pace over the forecast period.

North America Vertical Lift Module Market Trends

North American vertical lift module market is witnessing significant growth, buoyed by the increasing adoption of automation and efficiency-enhancing solutions across various industry sectors. The drive towards optimizing warehouse operations, coupled with the rising demand for space-saving storage solutions, is propelling the deployment of VLMs across the U.S. and Canada. As companies seek to improve operational efficiency, reduce costs, and enhance worker safety, VLMs are becoming an integral part of modern warehousing and manufacturing facilities.

Europe Vertical Lift Module Market Trends

The vertical lift module market in Europe is experiencing robust growth, driven by the region's focus on automation and efficiency in manufacturing and warehousing sectors, coupled with stringent regulations on occupational health and space optimization. Europe's strong manufacturing base in automotive, aerospace, and machinery, along with a rapidly expanding e-commerce sector, is pushing the demand for advanced storage solutions like VLMs. Furthermore, the emphasis on sustainability and the need to reduce operational costs are influencing European businesses to invest in VLM technology.

Key Vertical Lift Module Company Insights

Some of the key players operating in the market include Kardex Group, Hanel Storage Systems, Ferretto Group S.p.a, AutoCrib, Inc. among others.

-

The Kardex Group is a prominent global player in the automated storage solutions and material handling industry, specializing in Vertical Lift Modules (VLMs) among other technologies. Renowned for its innovative and efficient storage solutions, Kardex has established itself as a leader in the VLM market with its Kardex Remstar division. The company's VLM offerings, including the highly acclaimed Shuttle XP and Megamat RS models, cater to a wide array of industries seeking to optimize warehouse space, improve inventory management, enhance operational efficiency, and boost productivity.

-

Hanel Storage Systems is a leading international provider of innovative automated storage and retrieval solutions, including Vertical Lift Modules (VLMs) tailored for a wide range of industry requirements. Renowned for its pioneering advancements in the field of office and industrial storage, Hanel Storage Systems offers efficient and ergonomic VLM solutions such as the Lean-Lift and the Rotomat systems, which are distinguished by their ability to maximize storage density, enhance inventory control, and significantly improve retrieval times.

Savi Automation, Craftsman Storage Systems, Vidir Solutions, Inc. are some of the emerging market participants in the vertical lift module market.

-

Savi Automation specializes in providing state-of-the-art VLM systems tailored to meet the specific requirements of diverse industries, aiming to optimize warehouse and manufacturing operations through space-saving, efficiency-enhancing, and cost-effective storage solutions. Savi Automation's approach to leveraging advanced technologies, including robotics, IoT, and smart software interfaces, enables its VLM offerings to stand out by enhancing operational productivity, accuracy in inventory management, and overall workplace safety.

-

Craftsman Storage Systems specializing in the design and manufacture of VLMs that cater to a broad spectrum of industry sectors, company emphasizes enhancing operational efficiency, maximizing space utilization, and improving inventory management for its clients.

Key Vertical Lift Module Companies:

The following are the leading companies in the vertical lift module market. These companies collectively hold the largest market share and dictate industry trends.

- Kardex Group

- Hanel Storage Systems

- Ferretto Group S.p.a

- AutoCrib, Inc.

- Modula Inc.(System Logistics)

- Weland Lagersystem AB

- Schaefer Systems International Inc.

- Automha SPA

- Green Automated Solutions, Inc.

- Stanley Black & Decker Storage Solutions

- Savi Automation

- Craftsman Storage Systems

- Vidir Solutions, Inc.

Recent Developments

-

In March 2024, Greenspace Industrial recently unveiled its groundbreaking Modula Vertical Lift Module (VLM), marking a significant leap forward in the realm of automated storage and retrieval solutions. The Modula VLM is designed to revolutionize how businesses approach warehouse management and inventory control, offering unparalleled efficiency, space optimization, and accessibility.

-

In February 2023, Modula Inc. introduced a new range of dual-level delivery VLMs with enhanced safety features and improved performance for warehouse and manufacturing applications.

Vertical Lift Module Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 1,652.6 million

Revenue forecast in 2030

USD 2,783.8 million

Growth rate

CAGR of 9.1% from 2024 to 2030

Base year for estimation

2023

Historical data

2018 - 2022

Forecast period

2024 - 2030

Quantitative units

Revenue in USD million and CAGR from 2024 to 2030

Report coverage

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends

Segments covered

Delivery type, storage type, end-use, region

Regional scope

North America; Europe; Asia Pacific; Latin America; Middle East & Africa

Country Scope

U.S.; Canada; Mexico; Germany; France; Italy; UK; Spain; China; Japan; India; South Korea; Australia; Brazil; Argentina; South Africa; Saudi Arabia; UAE

Key companies profiled

Kardex Group; Hanel Storage Systems; Ferretto Group S.p.a; AutoCrib, Inc.; Modula Inc.(System Logistics); Weland Lagersystem AB; Schaefer Systems International Inc.; Automha SPA; Green Automated Solutions, Inc.; Stanley Black & Decker Storage Solutions; Savi Automation; Craftsman Storage Systems; Vidir Solutions, Inc.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Vertical Lift Module Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the vertical lift module market report based on delivery type, storage type, end- use, and region:

-

Delivery Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Single Level Delivery

-

Dual Level Delivery

-

-

Storage type Outlook (Revenue, USD Million, 2018 - 2030)

-

Non-refrigerated Type

-

Refrigerated Type

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Automotive

-

Metals & Machinery

-

Food & Beverages

-

Semiconductor & Electronics

-

E-commerce

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

Japan

-

China

-

India

-

Australia

-

South Korea

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global vertical lift module market size was estimated at USD 1,558.9 million in 2023 and is expected to reach USD 1,652.6 million in 2024

b. The global vertical lift module market, in terms of revenue, is expected to grow at a compound annual growth rate of 9.1% from 2024 to 2030 to reach USD 2,783.8 million by 2030

b. Asia Pacific dominated the vertical lift module market with a revenue share of 46.9% in 2023. Market driven by the growing focus on enhancing operational efficiency, inventory management, and space utilization in warehousing and manufacturing sectors. The rapid growth of e-commerce, automotive, electronics, and pharmaceutical industries in countries like China, India, Japan, South Korea, is fueling the demand for automated storage and retrieval systems (ASRS), including VLMs.

b. Some of the key players operating in the vertical lift module market include Kardex Group, Hanel Storage Systems, Ferretto Group S.p.a, AutoCrib, Inc., Modula Inc.(System Logistics), Weland Lagersystem AB, Schaefer Systems International Inc., Automha SPA, Green Automated Solutions, Inc., Stanley Black & Decker Storage Solutions, Savi Automation , Craftsman Storage Systems, Vidir Solutions, Inc.

b. The vertical lift module market is experiencing significant growth due to the increasing demand for automated storage and retrieval systems (ASRS) across multiple sectors. VLMs are an integral part of modern warehousing, logistics, and distribution centers, offering efficient storage solutions that save floor space, reduce worker fatigue, and improve inventory management through automated controls

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.