- Home

- »

- Micro Molding & Microspheres

- »

-

U.S. Thermoplastics Micro Molding Market Size Report, 2030GVR Report cover

![U.S. Thermoplastics Micro Molding Market Size, Share & Trends Report]()

U.S. Thermoplastics Micro Molding Market (2023 - 2030) Size, Share & Trends Analysis Report By Application (Automotive, Electronics, Medical, Packaging), And Segment Forecasts

- Report ID: GVR-4-68040-060-8

- Number of Report Pages: 110

- Format: PDF

- Historical Range: 2018 - 2021

- Forecast Period: 2023 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Market Size & Trends

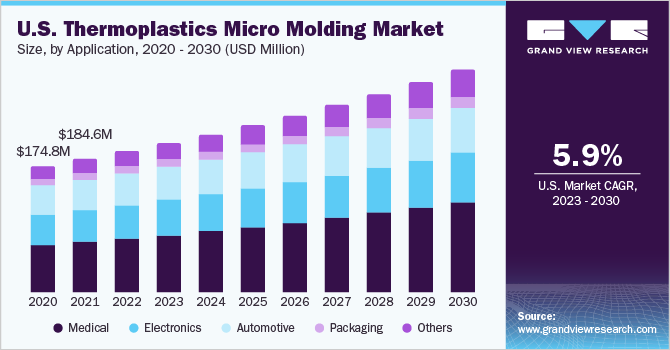

The U.S. thermoplastics micro molding market size was estimated at USD 195.1 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2023 to 2030 owing to its application in the production of micromechanical parts in the medical and electronics industry. Additionally, these moldings are used for precision and robust parts production which are used in automotive in order to produce lightweight and fuel-efficient vehicles. Thus, increasing consumer spending and rising automotive demand in the U.S. is expected to be beneficial for the overall market.

Micro molding is a highly specialized manufacturing process that produces micron-sized, high-precision thermoplastic parts and components. The process begins in a tooling department, where a mold with a cavity in the shape of the desired part is created. Rapid injection of thermoplastic or resin into the cavity results in the creation of the micro component or part.

The U.S. is a major market for thermoplastic micro molding on account of its highly developed economy, growing medical industry combined with a highly skilled workforce, and R&D initiatives to encourage product innovation. The development of electrical & electronics capacity additions and steady growth in the automotive and aerospace sectors are the factors that are expected to augment the market growth over the forecast period.

Prominent companies engaged in the production of thermoplastics micro molding include SMC Corporation, ACCU Mold LLC, ALC Precision (American Laubsher Corp) NY, and Makuta Technics Inc. These manufacturers supply their products to the market through several distribution channels including third-party agreements with wholesalers and vendors, direct supply agreements with automotive companies, and e-commerce portals.

These thermoplastics micro molding components are used in electrical & electronics, medical, and automotive applications owing to their increased toughness, high production volume, and long shelf life, along with easy scrap recycling. Moreover, the government of U.S. has passed stringent regulations regarding the reduction of overall weight of vehicles with the motive of controlling the carbon emission to prevent pollution. This is expected to result in rising demand for thermoplastics micro molding.

Thermoplastics micro molding is light-weighted thus reducing the overall weight of the structures. They have better-resolution feed options that lead to an equal pressure distribution inside the cavity, as micro molding machines can inject fractions of a gram with a high degree of precision. Moreover, micro molds are also employed in micro injection molding which is helpful in manufacturing micro medical components, in turn increasing the product demand.

The use of bioabsorbable polymers in thermoplastics micro molding is increasing due to rapid technological development and increased demand. Bioabsorbable materials are widely used in the medical industry as these polymers can be absorbed and dissolved by the human body. Their use reduces the number of surgical interventions required for specific (usually orthopaedic) treatments. The demand for these materials' applications grows parallelly with their innovations, thus increasing the product demand.

The prices of major raw materials are susceptible to fluctuations. For instance, the price of liquid crystal polymer is increasing owing to a shortage of supply and rising feedstock as well as energy costs. Several manufacturing industries are also involved in the utilization of raw materials necessary for the production of thermoplastic micro molding, which positively influences the bargaining power of suppliers. However, the manufacturers are also involved in backward integration, which eliminates the need for suppliers.

Additionally, thermoplastics micro molding is also considered sustainable and environmentally friendly. The material is recyclable and reusable and has the capability of becoming soft when heated, which allows molding, and when cooled, it returns back to its stiff state. The property of thermoplastics micro molding, including ease of remolding and reheating, allows manufacturers to recycle them for use in new applications, thus boosting the market demand.

Application Insights

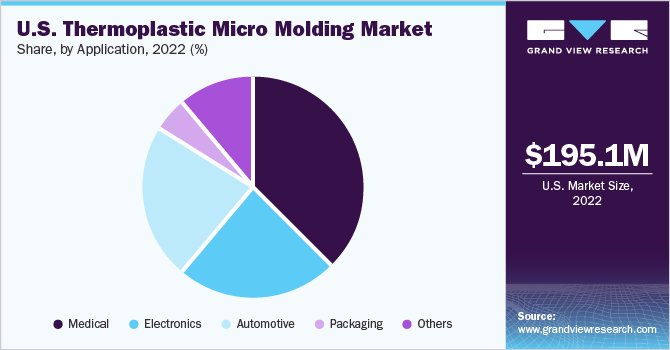

The U.S. thermoplastic micro molding market is segmented into automotive, electronic, medical, and packaging based on applications. The medical application exhibited as the largest and fastest growing market segment which accounted for 37.8% of the market. The use of small and sophisticated medical instruments are offering lucrative market opportunities for the thermoplastics micro molding market.

Additionally, thermoplastics micro molding is widely used in the manufacture of medical devices such as drug delivery devices, catheters, diagnostic systems, and optical, and hearing aid components. It is moreover useful for instruments used in minimally invasive surgeries, for instance, neurosurgery and aortic treatments. The abovementioned factors are projected to benefit the market growth over the forecast period.

Thermoplstics micromoulding is also widely used for manufacturing automobiles’ components which frequently require light and small components. Thermoplastics micromoulding is used for car underhood parts (e.g., engine or brakes) as well as various other automotive industry components such as various washers, clips, various buttons, door locking mechanism parts, micro plastic gear manufacturing, and switches. The above-mentioned factors are expected to boost market demand over the forecast period.

Thermoplastic micro molding can be used for production of variety of electronic components such as micro-optics, smart phones, laser-based devices, prisms, and lenses. Additionally, microelectronic components for communication technologies, computers, musical instruments, and other microelectronic products including connectors, plugs, computer chips, and switches. Microelectromechanical systems (MEMS) frequently require thermoplastic micro moulding manufacturing as well owing to an increased demand for innovative micromoulding products in the manufacturing industry.

For instance, BioMEMS (Biomedical Micro-Electro-Mechanical Systems), Point-of-Care diagnosing and Next Generation Sequencing (NGS) are under development for its potential usage in the thermoplstics micro molding industry. The rapid development of such modern technologies is expected to lead to a dramatic growth of thermoplastics micro molding in electronic industries.

Key Companies & Market Share Insights

The U.S. thermoplastics micro molding market is characterized by strong competition on account of the presence of prominent manufacturers serving major geographies across the U.S. These prominent manufacturers compete based on product quality and prices to increase their applications in the end-use industries. These players focus on achieving long-term contracts with players in the application industry to gain a competitive advantage.

Companies in the market are investing in R&D activities to provide the best suitable structure and product technology. Investment in research & development is expected to provide new opportunities for the players. In addition, properties such as low manufacturing cost, good insulation, and low processing cost are expected to attract new players into the market.

The manufacturers manufacture their products based on specification standards in the form of micro components, that are capable of operating in harsh environments prone to damages and adverse temperature. The product pricing quoted by manufacturers is based on the purchase volume and duration of the agreement with the company.

Medical, automotive, aerospace & defense, and electrical & electronics, marine industries are the major end-users of composites. Leading manufacturers in the industry are focusing improving product’s strength, durability, and temperature & pressure resistance, to compete with the threat of new entrants. In addition, the focus of manufacturers on improved quality is increasing as automotive manufacturers are emphasizing solutions for weight reduction and increase fuel economy. Some prominent players in the U.S. thermoplastics micro molding market include:

-

SMC CORPORATION

-

ACCU Mold LLC

-

American Precision Products

-

Isometric Micro Molding Inc

-

Makuta Technics Inc

-

MTD Micro Molding

-

Stack Plastics

-

Veejay Plastic Injection Molding Company

-

ALC Precision (American Laubsher Corp) NY

-

Micro Molding Solutions Inc.

U.S. Thermoplastics Micro Molding Market Report Scope

Report Attribute

Details

Revenue forecast in 2030

USD 308.1 million

Growth Rate

CAGR of 5.9% from 2023 to 2030

Base year for estimation

2022

Actual estimates/Historical data

2018 - 2021

Forecast period

2023 - 2030

Quantitative units

Revenue in USD Million and CAGR from 2023 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Country scope

U.S.

Segments covered

Application

Key companies profiled

SMC CORPORATION; ACCU Mold LLC; American Precision Products; Isometric Micro Molding Inc; Makuta Technics Inc; MTD Micro Molding; Stack Plastics; Veejay Plastic Injection Molding Company; ALC Precision (American Laubsher Corp) NY; Micro Molding Solutions Inc.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

U.S. Thermoplastics Micro Molding Market Report Segmentation

This report forecasts revenue growth at country level and provides an analysis of the industry trends of the sub-segment from 2018 to 2030. For this study, Grand View Research has segmented the U.S. thermoplastics micro molding market on the basis of application:

-

Application Outlook (Revenue, USD Million; 2018 - 2030)

-

Automotive

-

Electronics

-

Medical

-

Packaging

-

Others

-

Frequently Asked Questions About This Report

b. The U.S. thermoplastics micro molding market size was estimated at USD 195.1 million in 2022 and is expected to reach USD 206.3 million in 2023.

b. The U.S. thermoplastics micro molding market is expected to grow at a compound annual growth rate of 5.9% from 2023 to 2030 to reach USD 308.1 million by 2030.

b. Medical application dominated the U.S. thermoplastics micro molding market with a share of 37.8% in 2022 as it is used for manufacturing medical devices such as drug delivery devices, catheters, diagnostic systems, optical, and hearing aid components.

b. Some of the key players operating in the U.S. thermoplastics micro molding market include SMC CORPORATION, ACCU Mold LLC, American Precision Products, Isometric Micro Molding Inc, Makuta Technics Inc.

b. The key factor which is driving the U.S. thermoplastics micro molding market is their primary use in medical and automotive industries owing to their toughness, high production volume, long shelf life, and easy scrap recycling.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.