- Home

- »

- Advanced Interior Materials

- »

-

Metal Feeler Gauge Market Size And Share Report, 2030GVR Report cover

![Metal Feeler Gauge Market Size, Share & Trends Report]()

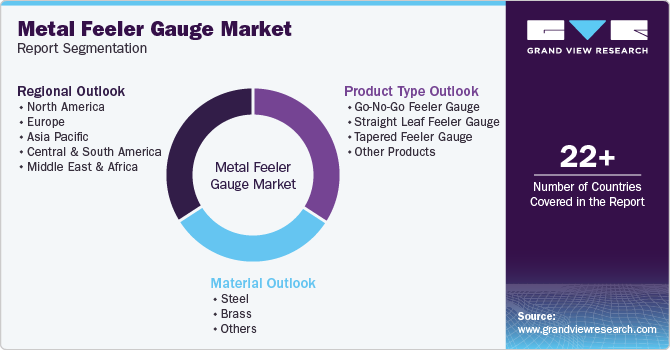

Metal Feeler Gauge Market (2024 - 2030) Size, Share & Trends Analysis Report By Material (Steel, Brass), By Product Type (Go-No-Go Feeler Gauge, Straight Leaf Feeler Gauge, Tapered Feeler Gauge), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-421-5

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Metal Feeler Gauge Market Size & Trends

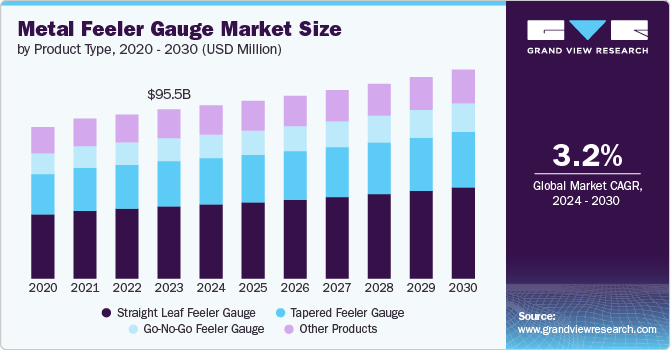

The global metal feeler gauge market size was estimated at USD 95.5 million in 2023 and is expected to grow at a CAGR of 3.2% from 2024 to 2030. The growth of this market can be attributed to the rising focus on precision and quality control in various industries, such as aerospace, automotive, and manufacturing. The need for accurate measuring tools is anticipated to increase with advancements in these industries to ensure mechanical components' smooth functioning and longevity. In addition, growth in maintenance and repair activities due to the increasing complexity of machinery and equipment is further expected to fuel the demand for metal feeler gauges over the forecast period.

The growing demand for go/no-go feeler gauges is driven by several key factors that reflect the increasing relevance and utility of these precision measurement tools across various industries. One significant factor contributing to this demand is the increasing usage of these gauges in engineering and construction applications. Feeler gauges are essential for measuring the gap between two objects, and their application in these fields has become more prevalent, indicating a growing need for these tools. For example, feeler gauges are commonly used for setting the gap on spark plugs in combustion engines, ensuring optimal performance and efficiency.

Furthermore, the awareness of the benefits of feeler gauges across different industries has led to an increased adoption of these tools. As industries recognize the importance of precise measurements and gap adjustments, the demand for high-quality feeler gauges, including go/no-go variants, has surged. This heightened awareness has contributed to this market's expansion and the growing preference for these specialized measurement tools.

Moreover, technological progress in related industries has played a pivotal role in driving the demand for go/no-go feeler gauges. Advancements in engineering, manufacturing, and precision measurement technologies have created opportunities for the integration of these tools into various processes. As a result, the demand for specialized feeler gauges, such as the go/no-go variants, has notably increased, reflecting the evolving needs of modern industrial applications.

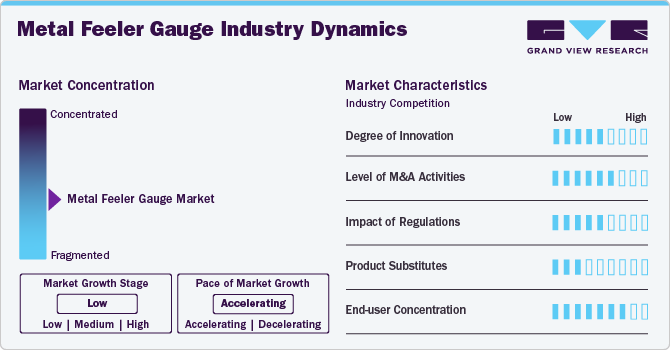

Market Concentration & Characteristics

The metal feeler gauge industry is characterized by a wide range of local and international manufacturers competing to increase their industry shares. Key players are adopting various strategies, such as diversifying their product offerings and research and development, to gain a competitive edge in this market. These players are forming strategic partnerships with industrial manufacturers and suppliers to expand market reach and enhance distribution networks.

The market is considerably fragmented with the presence of several manufacturers. Factors such as product similarities, fixed costs, and exit barriers contribute to the competitive rivalry in the market. Manufacturers compete on factors such as product quality, customization capabilities, delivery times, and pricing.

The key end-use industries using metal gauges are automotive, aerospace, defense, and industrial manufacturing. Therefore, the market encompasses the procurement of raw materials, technological development and manufacturing, supply chain management, and the delivery of the finished product to the end-users. Each stage in the value chain contributes to the overall production and distribution of metal feeler gauges, ultimately leading to customer satisfaction and competitive advantage.

Metal feeler gauge industry is segmented by distribution channels, including both online and offline channels. This segmentation reflects the diverse ways in which these products reach the end-users, catering to different customer preferences and industry requirements. With the increasing prominence of e-commerce, online distribution channels have become a significant avenue for the sales of metal feeler gauges. Online platforms provide a convenient and accessible way for customers to browse, compare, and purchase these precision tools. Companies may leverage e-commerce platforms, their own websites, or online marketplaces to reach a broader customer base and facilitate direct sales to end-users.

Product Type Insights

Straight leaf feeler gauge accounted for the largest market share of 42.7% in 2023 and is expected to grow at a significant rate from 2024 to 2030. The straight leaves of feeler gauges may also be referred to as parallel leaves. These leaves have sides that run parallel from the locking screw to the tip, with smooth, rounded edges for comfort and safety when handling. Straight leaves of these gauges are designed to provide a wide clearance between surfaces that are required to be parallel. Due to this feature, machinists and engineers often choose straight-leaf gauges. The straight blade design ensures that parts are not sliding over the top of the gauge when measuring a clearance. The consistent width also prevents parts from sliding off the sides of the gauge.

Tapered-feeler gauges are crafted from high-grade precision gauge steel. The leaves of these gauges are tapered to make it easy to work with them in tight spaces. Each leaf of tapered-feeler gauges is etched with a size number, thereby indicating its thickness in thousandths of an inch and its millimeter equivalent. A knurled lock nut holds the leaves in the desired position. Tapered leaves are usually narrow toward the tip and are generally shorter than straight leaves.

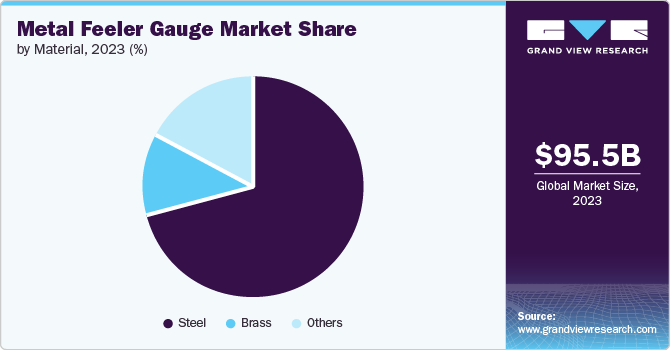

Material Insights

Steel material segment accounted for the largest revenue share in 2023 with over 71.1% in 2023. The steel feeler gauge is made from high-carbon, close-grained spring steel. It is 1/2 inch wide and made of spring steel stock. The carbon content in the steel makes sure that the material does not compress, providing constant accuracy, which is the most critical aspect of this precision tool. The feeler gauge is honed and polished to exact specifications. This tool is primarily used in maintenance, manufacturing, die, and tool operations, where highly tight tolerances or close spacing must be checked.

Stainless steel retains its mechanical properties over various temperatures, from cryogenic to high temperatures. This thermal stability makes stainless steel gauge ideal for marine, aerospace, automotive, and industrial applications. Feeler gauges in these applications must withstand extreme temperature variations without deforming or degrading. Stainless steel feeler is used in marine, automotive, food, and aerospace industries for engine components, exhaust systems, structural assemblies, and others.

Regional Insights

North America includes economies such as the U.S., Canada, and Mexico. The region is experiencing notable expansion, fueled by a rich mix of industrial activities in the region. The increase heavily influences this surge in manufacturing operations across North America, parallelly increasing the demand for metal feeler gauges in the region.

U.S. Metal Feeler Gauge Market Trends

The metal feeler gauge market in the U.S.revenueis expected to grow with a CAGR of 3.3% over the forecast period. Metal feeler gauges are crucial in automotive manufacturing. They also find applications in engine parts for measuring valve clearance, bearing clearance, spark plug gaps, and others. Following the economic challenges of the first half of 2022 due to the pandemic and Russia-Ukraine conflict, the recovery in automotive sales and production has led to a noticeable boost in the need for metal feeler gauges within the U.S.

Asia Pacific Metal Feeler Gauge Market Trends

Asia Pacific metal feeler gauges is projected to be the largest market in terms of revenue over the forecast period. This market in this region was valued at USD 37.1 million in 2023. Rapid industrialization and the expanding manufacturing sector in developing economies such as China, India, and South Korea have increased focus on quality control and precision engineering. Advances in technology and the rising production capabilities of companies have fueled the need for accurate measurement tools to ensure the performance and reliability of machinery. These factors are expected to bolster the demand for metal feeler gauges over the forecast period.

The metal feeler gauge market in India is projected to witness expansion owing to the anticipated growth of automobile and manufacturing sectors over the forecast period. This is because metal feeler gauges are vital components used in these industries to ensure precise automotive products with minimal tolerance for gaps. For instance, in March 2024, Tata Motors signed a Memorandum of Understanding (MoU) with the Government of Tamil Nadu (India) to establish a vehicle manufacturing plant in the state. The project is expected to cost around USD 859 million and will be set up within the next five years.

China metal feeler gauge market is driven by the growth of manufacturing sector in this country. According to the State Council Information Office of China (SCIO), the country's total value-added industrial production was estimated to be around USD 5.6 trillion in 2023. According to the Organization for Economic Co-operation and Development (OECD), China accounted for 35% of the global output in 2023. The country's well-established manufacturing sector generates demand for metal feeler gauges, especially in the automotive, R&D, transportation, die casting, and plastic molding industries. Furthermore, increased investments in special-purpose machinery, automobiles, and electrical machinery in China are also expected to drive the demand for metal feeler gauges in the coming years.

Europe Metal Feeler Gauge Market Trends

The metal feeler gauge market in Europe is the second largest in terms of revenue share. This can be attributed to the presence of developed economies in the region, such as Germany, the UK, France, and Italy, with high automotive production. The strong emphasis on automotive manufacturing is contributing to the growth of this region

Germany metal feeler gauge market is driven by the automotive manufacturing industry is rising as they play a crucial role in precisely adjusting various automotive components, including valve clearances, spark plug gaps, and bearing clearances. The pursuit of engineering precision and the adherence to strict quality standards by automobile manufacturers are key factors driving the increased demand for sophisticated metal feeler gauges, which are essential for improving the performance and dependability of vehicles. With Germany at the forefront of automotive technological innovations, particularly in the development of electric and autonomous vehicles, there is an anticipated growth in the market for specialized metal feeler gauges, designed to fulfill the specific needs of these advanced applications.

Central & South America Metal Feeler Gauge Market Trends

The metal feeler gauge market in Central & South America is expected to grow at a CAGR of 2.6% in terms of revenue over the forecast period. This growth is attributed to the expanding automotive and manufacturing sectors. The rising production of vehicles necessitates precise measurement tools to ensure quality and efficiency, thereby fueling the demand for metal feeler gauges in the region.

Middle East & Africa Metal Feeler Gauge Market Trends

Middle East and Africa metal feeler gauge marketis expected to witness significant growth in the coming years, owing to the growing presence of industrial manufacturing plants in the region which are driving the demand for the product over the coming years.

Key Metal Feeler Gauge Company Insights

Some of the key players operating in the market include Eastern Gage and Stanley Black & Decker, Inc. (Stanley):

-

Eastern Gage, formerly known as Eastern Industries Inc., is a global manufacturer of precision feeler gauges. The company offers its products for various applications, including aerospace and defense, as well as to smaller local players manufacturers, and consumer goods companies. Additionally, the company produces custom products for machine components, medical products, hand tools, automotive parts, and aerospace products.

-

Stanley Black & Decker, Inc. (Stanley) is a global provider of industrial equipment with expertise in manufacturing, marketing, and selling an extensive range of tools, accessories, and engineered fastening systems. Its product portfolio includes hand tools, power tools, related accessories, and cutting-edge equipment for video surveillance, fire alarm monitoring, and system maintenance.

SKF and MW Industries, Inc. are some of the emerging market participants.

-

SKF is an industrial products manufacturing company offering a varied range of high-quality solutions, including bearings, lubrication, magnetic systems, power transmission products, coupling systems, and seals. It has a global presence across approximately 130 countries, boasting over 29 remanufacturing sites, 15 technology centers, and 17,000 distributor locations globally.

-

MW Industries, Inc. is engaged in the manufacture of feeler gauges, coiled springs, machined springs, flat springs, fasteners, metal bellows, and couplings. The company has 30 facilities operating on an international scale. It has several subsidiaries, such as Accurate Screw Machine, Allstar Fasteners, Ameriflex, Elgin Fastener Group, Capital Spring, BellowsTech, Engineered Spring Products, Hyperco, Ideal Fasteners, and RAF Electronic Hardware.

Key Metal Feeler Gauge Companies:

The following are the leading companies in the metal feeler gauge market. These companies collectively hold the largest market share and dictate industry trends.

- Eastern Industries, Inc.

- Starrett

- Stanley Black & Decker, Inc.

- MW Industries, Inc.

- Precision Brand

- SKF

- Yorkshire Precision Gauges

- Bahco

- GEDORE Werkzeugfabrik GmbH & Co. KG

- Vogel Germany GmbH & Co. KG

Recent Developments

-

In April 2024, Waygate Technologies-a Baker Hughes business that offers nondestructive testing solutions for industrial inspection-launched a new ultrasonic precision thickness gauge, namely Krautkramer CL Go+. This versatile and convenient inspection tool is especially suitable for components used in the aerospace and automotive industries. It accurately measures cast and stamped components developed from steel, aluminum, bronze, and copper. Additionally, it is effective for inspecting tubes, machined workpieces, metal plates, plastics parts, chemically milled components, composites, and glass.

Metal Feeler Gauge Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 97.8 million

Revenue forecast in 2030

USD 118.1 million

Growth rate

CAGR of 3.2% from 2024 to 2030

Actual data

2018 - 2023

Forecast period

2024 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2024 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Material, Product type, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK, France; Italy, Spain; Germany, China; India; Japan; Australia; Brazil

Key companies profiled

Eastern Industries, Inc., Starrett, Stanley Black & Decker, Inc., MW Industries, Inc., Precision Brand, SKF, Yorkshire Precision Gauges, Bahco, GEDORE, Werkzeugfabrik GmbH & Co. KG, Vogel Germany GmbH & Co. KG

Customization scope

Free report customization (equivalent up to 8 analysts’ working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Metal Feeler Gauge Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global metal feeler gauge market report based on material, product type, and region:

-

Product Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Go-No-Go Feeler Gauge

-

Straight Leaf Feeler Gauge

-

Tapered Feeler Gauge

-

Other Products

-

-

Material Outlook (Revenue, USD Million, 2018 - 2030)

-

Steel

-

Brass

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

France

-

Italy

-

Spain

-

Germany

-

-

Asia Pacific

-

China

-

India

-

Japan

-

Australia

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global metal feeler gauge market size was estimated at USD 95.5 million in 2023 and is expected to reach USD 97.8 million in 2024.

b. The global metal feeler gauge market is expected to grow at a compound annual growth rate of 3.2% from 2024 to 2030 to reach USD 118.1 million by 2030.

b. Steel material segment market dominated the market with a share of 71.1% in 2023, owing to its gauges owing to their superior strength, durability, and resistance to corrosion, makes them ideal for precision measurement in harsh industrial environments.

b. Some of the key players operating in the metal feeler gauge market are Eastern Industries, Inc., Starrett, Stanley Black & Decker, Inc., MW Industries, Inc., Precision Brand, SKF, Yorkshire Precision Gauges, Bahco, GEDORE, Werkzeugfabrik GmbH & Co. KG, and Vogel Germany GmbH & Co. KG

b. The key factors that drives metal feeler gauge market is rising focus on precision and quality control in various industries, such as aerospace, automotive, and manufacturing.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.