- Home

- »

- Advanced Interior Materials

- »

-

Glass Lined Equipment Market Size, Industry Report, 2033GVR Report cover

![Glass Lined Equipment Market Size, Share & Trends Report]()

Glass Lined Equipment Market (2025 - 2033) Size, Share & Trends Analysis Report By Product (Reactors, Agitators, Storage Tanks, Heat Exchangers), By End Use (Pharmaceutical, Chemicals, Agriculture, Food & Beverage), And Segment Forecasts

- Report ID: GVR-4-68040-142-3

- Number of Report Pages: 169

- Format: PDF

- Historical Range: 2021 - 2024

- Forecast Period: 2025 - 2033

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Glass Lined Equipment Market Summary

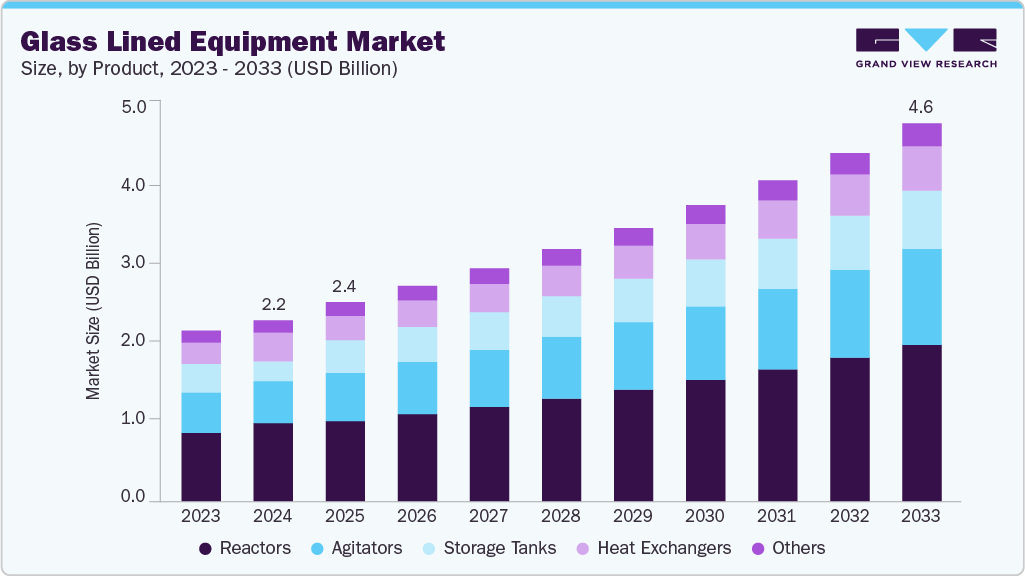

The global glass lined equipment market size was estimated at USD 2,229.3 million in 2024 and is projected to reach USD 4,571.5 million by 2033, growing at a CAGR of 8.3% from 2025 to 2033. The demand for glass-lined equipment is primarily driven by its exceptional corrosion resistance and durability, making it a preferred choice in industries such as pharmaceuticals, chemicals, and food processing.

Key Market Trends & Insights

- Asia Pacific dominated the glass lined equipment market with the largest revenue share of 40.1% in 2024.

- The glass lined equipment market in India is expected to grow at a rapid CAGR of 10.2% from 2025 to 2033.

- Based on product, the agitators segment is projected to expand at a CAGR of 9.0% over the forecast period.

- Based on end use, the pharmaceuticals segment is expected to grow at a CAGR of 9.0% from 2025 to 2033 in terms of revenue.

Market Size & Forecast

- 2024 Market Size: USD 2,229.3 Million

- 2033 Projected Market Size: USD 4,571.5 Million

- CAGR (2025-2033): 8.3%

- Asia Pacific: Largest market in 2024

The inert nature of glass lining ensures product purity, crucial for industries with stringent quality standards. In addition, the increasing focus on environmental sustainability has propelled the demand for glass-lined equipment, as it is a recyclable and eco-friendly alternative. Moreover, stringent regulatory standards regarding product safety and hygiene further contribute to market growth, as glass-lined equipment effectively meets these criteria. The rising investments in infrastructure development and the expansion of manufacturing facilities globally also play a significant role in the market's upward trajectory.

Market Concentration & Characteristics

The glass lined equipment industry exhibits a moderate to high level of concentration, with a few global manufacturers, including Pfaudler, De Dietrich Process Systems, Thaletec, and GMM Pfaudler, holding significant market shares. These players dominate due to their strong technological expertise, extensive product portfolios, and established relationships with end users in the chemical, pharmaceutical, and food processing industries. Smaller regional manufacturers primarily compete on cost and customization, although entry barriers remain high due to stringent quality requirements and specialized production processes. Consolidation through mergers and acquisitions has further strengthened the dominance of top-tier players, expanding their geographic reach and service capabilities.

Ongoing advancements in material durability, coating technologies, and digital monitoring systems drive innovation in the glass lined equipment industry. Manufacturers are developing enhanced glass formulations with higher corrosion and thermal shock resistance to extend equipment lifespan and performance under aggressive chemical conditions. Integration of IoT-based monitoring and predictive maintenance solutions is emerging as a differentiating factor, enabling users to optimize operational efficiency and minimize downtime. In addition, growing emphasis on custom-engineered reactor designs and modular configurations reflects the market’s shift toward tailored process solutions that meet diverse industry-specific needs.

The market is strongly influenced by safety, environmental, and manufacturing regulations, particularly in end-use sectors such as pharmaceuticals, food & beverages, and specialty chemicals. Compliance with standards such as ASME, ISO, and FDA requirements governs the selection of materials, design of equipment, and quality assurance procedures. Environmental regulations promoting safer chemical processing and containment of hazardous materials have increased the adoption of glass-lined reactors and storage vessels. Furthermore, stricter Good Manufacturing Practice (GMP) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) compliance obligations drive end users to prioritize certified suppliers, reinforcing the importance of regulatory adherence as a competitive differentiator.

Product Insights

Based on product, the reactors segment led the market, accounting for 40.2% of the global market share in 2024. Reactors are a crucial component of production lines in modern process plants, and they are widely employed in various industries, including pharmaceuticals, petrochemicals, pesticides, light industries, food, dyes, and scientific research. In the chemical and pharmaceutical industries, glass lined reactors are used owing to their chemical compatibility.

The increasing demand for glass-lined agitators is primarily driven by their pivotal role in enhancing mixing efficiency and optimizing chemical processes across various industries, including pharmaceuticals, chemicals, and food processing. These agitators provide a corrosion-resistant and inert solution, essential for maintaining product purity and quality in harsh chemical environments. As industries strive for operational excellence and adherence to stringent quality standards, the reliability and durability of these agitators become indispensable, making them a key enabler for efficient mixing, reaction control, and overall process optimization.

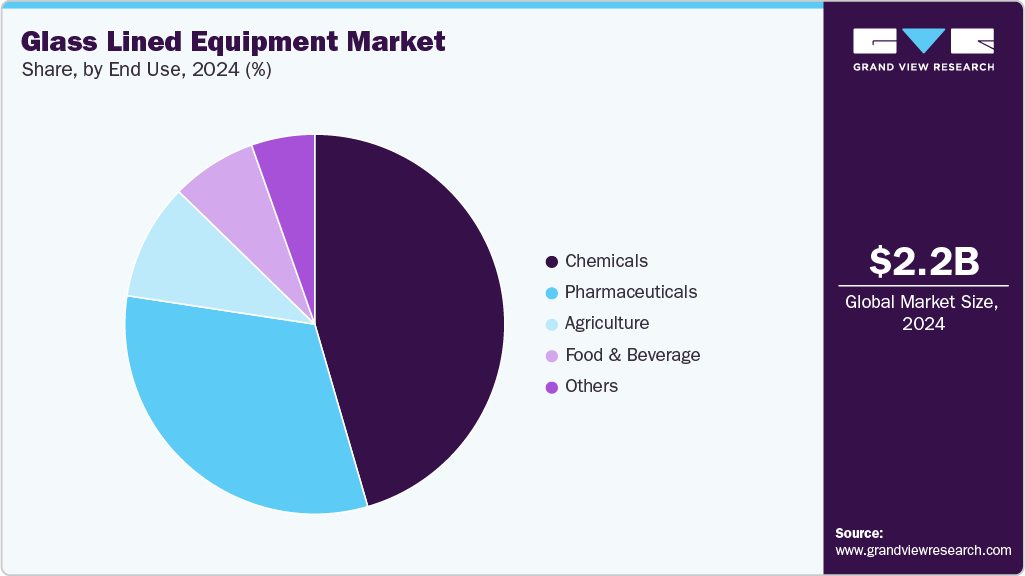

End Use Insights

The chemicals segment led the market, accounting for 45.5% of the global market share in 2024. Glass-lined agitators are essential for crude oil storage tanks, as well as for the refining and processing phases in the petrochemical industry. In crude oil storage tanks, the deposition of sludge, which is composed of both inorganic and organic materials, must be agitated to ensure that it remains suspended off the bottom. This reduces the difficulty of the downstream process and prevents settling in the tank, which can impact the tank's capacity and the agitator's performance.

Various types of glass lined equipment are utilized in the pharmaceutical manufacturing industry. The functions and applications of a pharmaceutical department are to determine the criteria for selecting glass lined equipment for vessels. In the pharmaceutical industry, some departments use this equipment as their primary vessel, for instance, the injectable department, where the use of conventional equipment is not feasible.

Regional Insights

The Asia Pacific glass lined equipment market dominated the global revenue share in 2024, accounting for a 40.1% market share. The pharmaceutical industries in China, Japan, and India are anticipated to experience significant growth in the coming years, driven by the continuous increase in the aging populations of these countries. This is anticipated to lead pharmaceutical companies to invest in the region. All these factors are expected to increase the adoption of technologically advanced processes in the region, driving market expansion.

China Glass Lined Equipment Market Trends

The glass lined equipment market in China is expanding rapidly, driven by growth in the chemical, pharmaceutical, and specialty manufacturing sectors. Strong government support for sustainable and high-quality industrial processes has boosted demand for corrosion-resistant and contamination-free systems. With ongoing investments in domestic production and export capacity, China continues to strengthen its role as a global manufacturing hub for glass-lined equipment.

India glass lined equipment market is growing steadily, supported by rising demand from the pharmaceutical, agrochemical, and specialty chemical industries. The increasing focus on environmental compliance, process safety, and equipment durability is driving adoption, while government initiatives promoting local manufacturing under the “Make in India” program are enhancing domestic production. Replacement demand and modernization in existing plants are also contributing to sustained market growth.

North America Glass Lined Equipment Market Trends

The glass lined equipment market in North America is propelled by the expansion of the pharmaceutical, biotechnology, and food processing industries, sectors that demand high-purity, corrosion-resistant systems. The region’s mature regulatory environment, including stringent safety and hygiene standards, supports strong adoption of glass-lined reactors and storage vessels designed for process safety and product integrity.

The U.S. glass lined equipment market is underpinned by strong demand from the pharmaceutical, biotechnology, and specialty chemical sectors, where purity, corrosion resistance, and regulatory compliance are critical. Domestic manufacturers are investing in improved glass formulations and modular reactor systems to meet the evolving requirements of high-purity processing environments. At the same time, growth is being supported by upgrades and capacity expansions in life-sciences manufacturing and food-grade processing that favour glass-lined vessels for their inert surfaces.

Europe Personal Glass Lined Equipment Market Trends

The glass lined equipment market in Europe is driven by the demand of the chemical and pharmaceutical industries for high-performance and hygienic equipment, as well as the presence of engineering-intensive manufacturing hubs. European operators increasingly invest in glass-lined equipment due to its ability to meet rigorous contamination control, durability, and regulatory compliance requirements in batch processing and specialty manufacturing.

Germany glass lined equipment market is supported by the country’s advanced chemical-processing and engineering base, stringent industrial safety standards, and high expectations for equipment longevity and reliability. German users are increasingly favouring glass-lined reactors and storage tanks in the food & beverage, chemical intermediates, and pharmaceutical industries due to the material’s combination of inertness, cleanability, and provenance. Local manufacturers and engineering firms are responding with tailored designs, enhanced process documentation, and certifications to align with German and European quality standards.

The glass lined equipment market in the UK is benefiting from strong demand in the pharmaceutical and food-processing segments, where hygiene, contamination control, and corrosion resistance are paramount. UK suppliers and licensors emphasise glass-lined equipment as a competitive solution for batch-process industries, supported by the country’s regulatory framework around safety and product purity. As manufacturing operations shift to higher-value, lower-volume production, the UK market is seeing rising uptake of modular and custom glass-lined systems that address flexibility, cleanability, and rapid turnaround.

Latin America Glass Lined Equipment Market Trends

The glass lined equipment market in Latin America is emerging as industrial facilities in pharmaceutical, agrochemical, and food processing sectors upgrade their infrastructure. Growth is anchored by increasing investments in manufacturing modernization and stronger importation of advanced process equipment, even though local capacity and technological adoption remain in early stages.

Brazil glass lined equipment market is growing as pharmaceutical, agrochemical, and food processing industries expand and modernize. The drive for higher manufacturing standards and chemical-process safety is leading Brazilian operators to invest in glass-lined reactors and vessels that offer enhanced corrosion-resistance and contamination control. While local capacity remains more limited compared to mature markets, growth opportunities are emerging as Brazil emphasizes advanced manufacturing and seeks to upgrade its process-equipment base.

Middle East & Africa Glass Lined Equipment Market Trends

The glass lined equipment market in the Middle East & Africa region is gaining momentum as a growth market, supported by industrial diversification and infrastructure development, particularly in the Gulf Cooperation Council (GCC) states. The need for durable, corrosion-resistant systems suitable for harsh operating environments and specialized chemical processing drives demand. However, market maturity and regional supply chains are still under development.

Saudi Arabia glass lined equipment market growth is closely tied to the kingdom’s investment in chemical, pharmaceutical, and food-processing infrastructure as part of its industrial diversification plans. As local and regional manufacturing facilities are developed, the demand for glass-lined equipment that can handle corrosive reagents, maintain product purity, and meet international quality standards is increasing. Suppliers are leveraging this to introduce glass-lined reactors and storage tanks suited to the harsh operating conditions and high-reliability requirements of the Middle East region.

Key Glass Lined Equipment Company Insights

Some of the key players operating in the market include GMM Pfaudler and Buchiglasuster.

-

GMM Pfaudler is a global engineering and manufacturing company specializing in corrosion-resistant technologies and systems for the chemical, pharmaceutical, food, and process industries. The company offers a broad product range, including glass-lined equipment, reactors, filtration systems, and drying systems. Originating in India, the company has a global footprint spanning multiple continents, focusing on integrated process and system solutions, as well as lifecycle services.

-

Buchiglasuster is a Swiss manufacturer specializing in advanced reactor systems and pilot plants for the chemical and pharmaceutical industries, delivering equipment from laboratory scale through to production. Known for its glass, glass-lined steel, and pressure-reactor solutions, the company emphasizes high performance under challenging conditions (corrosion, pressure). It supports customers through a full lifecycle of services, from design to after-sales.

Key Glass Lined Equipment Companies:

The following are the leading companies in the glass lined equipment market. These companies collectively hold the largest market share and dictate industry trends.

- GMM Pfaudler

- Büchiglasuster

- SGT Glass-Lined Equipment Co., Ltd.

- HLE Glascoat

- THALETEC

- 3V Tech S.p.A.

- Standard Group of Companies Ltd.

- Zibo Taiji Industrial Enamel Co., Ltd.

- Jiangsu Yangyang Chemical Equipments Manufacture Co., Ltd.

- SACHIN INDUSTRIES LTD.

- JUNG HYUN PLANT

- Goel Scientific Glass Works Ltd.

- Glasigen Lined Equipment PVT LTD.

- TANGLIAN

- PFG GLASSKEM INC.

Recent Developments

-

In May 2025, Zibo Taiji Industrial Enamel Co., Ltd. announced the successful production of a 100,000-liter large-scale glass-lined reactor. This milestone marks a significant advancement in the company’s engineering innovation and manufacturing capabilities, enhancing its ability to supply high-capacity, reliable equipment to the global chemical, pharmaceutical, and process industries.

-

In May 2025, Standard Glass Lining Technology Ltd. (SGLTL) announced a partnership with AGI Group to develop glass-lined shell and tube heat exchangers in India jointly. This collaboration grants SGLTL a 20-year manufacturing and marketing license, enhancing its technical capabilities and market reach.

Glass Lined Equipment Market Report Scope

Report Attribute

Details

Market size value in 2023

USD 2,408.9 million

Revenue forecast in 2033

USD 4,571.5 million

Growth rate

CAGR of 8.3% from 2025 to 2033

Base year for estimation

2024

Historical data

2021 - 2024

Forecast period

2025 - 2033

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2033

Report coverage

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends

Segments covered

Product, end use, region

Regional scope

North America; Europe; Asia Pacific; Middle East & Africa; Central & South America

Country Scope

U.S.; Canada; Mexico; Germany; France; Italy; UK; Spain; China; India; Japan; South Korea; Australia; Brazil; Argentina; Saudi Arabia; South Africa

Key companies profiled

GMM Pfaudler; Büchiglasuster; SGT Glass-Lined Equipment Co., Ltd.; HLE Glascoat; THALETEC; 3V Tech S.p.A.; Standard Group of Companies Ltd.; Zibo Taiji Industrial Enamel Co., Ltd.; Jiangsu Yangyang Chemical Equipments Manufacture Co., Ltd.; SACHIN INDUSTRIES LTD.; JUNG HYUN PLANT; Goel Scientific Glass Works Ltd.; Glasigen Lined Equipment Pvt. Ltd.; TANGLIAN; PFG GLASSKEM INC.

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Glass Lined Equipment Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2021 to 2033. For this study, Grand View Research has segmented the global glass lined equipment market based on product, end use, and region:

-

Product Outlook (Revenue, USD Million, 2021 - 2033)

-

Reactors

-

Agitators

-

Heat Exchangers

-

Storage Tanks

-

Others

-

-

End Use Outlook (Revenue, USD Million, 2021 - 2033)

-

Pharmaceuticals

-

API

-

Others

-

-

Chemicals

-

Petrochemicals

-

Specialty Chemical

-

Others

-

-

Agriculture

-

Food & Beverage

-

Others

-

-

Region Outlook (Revenue, USD Million, 2021 - 2033)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

France

-

Italy

-

UK

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

Australia

-

India

-

South Korea

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Saudi Arabia

-

South Africa

-

-

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.