- Home

- »

- Advanced Interior Materials

- »

-

Electrospun Fibers Market Size, Share & Growth Report 2030GVR Report cover

![Electrospun Fibers Market Size, Share & Trends Report]()

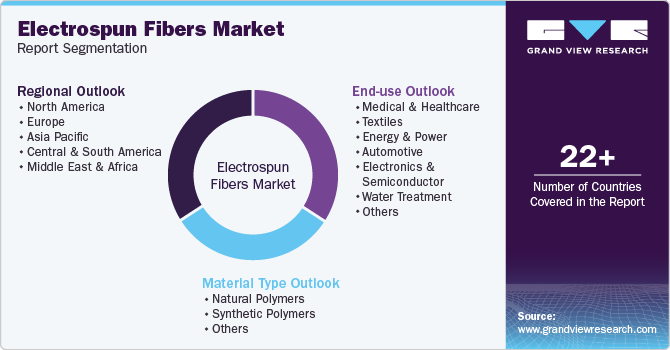

Electrospun Fibers Market (2024 - 2030) Size, Share & Trends Analysis Report By Material Type (Natural Polymers, Synthetic Polymers), By End-use (Medical & Healthcare, Aerospace & Defense), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-458-3

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

Electrospun Fibers Market Summary

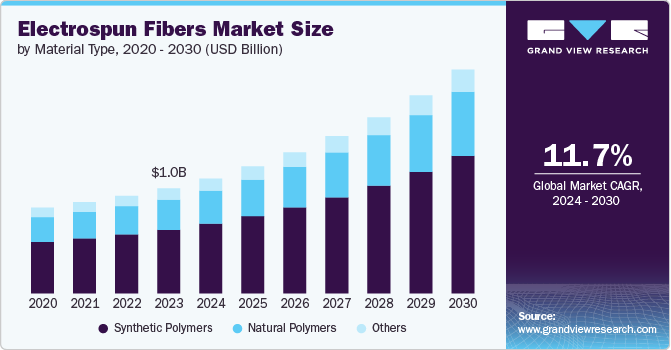

The global electrospun fibers market size was estimated at USD 1.0 billion in 2023 and is projected to reach USD 2.1 billion by 2030, growing at a CAGR of 11.7% from 2024 to 2030. Electrospun fibers have distinct characteristics such as a high surface area-to-volume ratio, small pore size, and high porosity, which make them ideal for a wide range of applications.

Key Market Trends & Insights

- The North America electrospun fibers market dominated the industry with the highest revenue share of 38.1% in 2023.

- The U.S. is a global leader in healthcare innovation, with heavy investment in medical devices, tissue engineering, and drug delivery systems.

- Based on material type, the synthetic polymer segment led the market with the largest revenue share of 60.7% in 2023 and is forecasted to grow at a significant CAGR from 2024 to 2030.

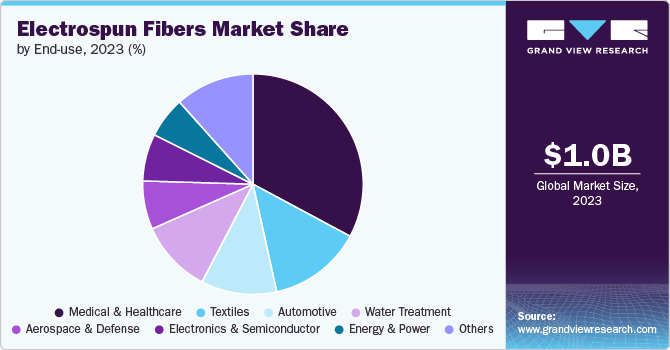

- In terms of end use, the medical & healthcare dominated the market with a revenue share of 32.8% in 2023.

Market Size & Forecast

- 2023 Market Size: USD 1.0 billion

- 2030 Projected Market Size: USD 2.1 billion

- CAGR (2024-2030): 11.7%

- North America: Largest market in 2023

These fibers can be produced from various polymers and materials, allowing for flexibility in their mechanical, thermal, and chemical properties. This versatility drives innovation in industries such as filtration, biomedical applications, and energy storage, where specialized materials are increasingly required for more efficient and high-performance solutions.

In the medical and healthcare sectors, electrospun fibers are being widely adopted for applications such as drug delivery systems, wound dressings, tissue engineering scaffolds, and medical implants. The biocompatibility and the ability to fabricate fibers at a nanoscale enable better integration with biological tissues, enhancing their effectiveness in medical treatments. With the rise in chronic diseases, aging populations, and increasing healthcare expenditure globally, the demand for electrospun fibers in medical applications is expected to expand significantly.

There is also a growing demand for electrospun fibers in environmental applications, particularly in filtration systems. Electrospun membranes are used for air and water purification due to their fine fiber structure that can trap pollutants and particles at a nanoscale level. As concerns about environmental sustainability, pollution control, and water scarcity increase, industries are seeking advanced filtration technologies. The electrospun fibers market benefits from this trend as companies look to adopt more effective and eco-friendly solutions in their processes.

The growth in demand is also supported by advancements in electrospinning technology. Innovations in manufacturing processes have made the production of electrospun fibers more cost-effective and scalable, making them more accessible for commercial applications. As the technology matures, economies of scale are driving down costs, further increasing adoption across industries.

Material Type Insights

The synthetic polymer segment led the market with the largest revenue share of 60.7% in 2023 and is forecasted to grow at a significant CAGR from 2024 to 2030. Synthetic polymers, such as polyethylene oxide (PEO), polyvinyl alcohol (PVA), polycaprolactone (PCL), and poly(lactic-co-glycolic acid) (PLGA), hold the largest industry share. Synthetic polymers offer a wide range of properties like strength, flexibility, and thermal resistance, which are crucial in various applications such as filtration, medical devices, and textiles. Their adaptability to different needs makes them the preferred choice for manufacturers.

Moreover, these are generally more affordable to produce in large quantities compared to natural polymers, which makes them more viable for industrial-scale applications. These materials can be easily modified to achieve specific properties like hydrophilicity or hydrophobicity, which makes them suitable for sectors such as biomedical engineering, where precise material behavior is necessary.

Natural polymers like cellulose, chitosan, collagen, and silk fibroin are gaining momentum but occupy a smaller market share than synthetics. These are favored in biomedical and pharmaceutical applications due to their inherent biocompatibility and biodegradability. This makes them ideal for medical implants, tissue scaffolds, and drug delivery systems that require minimal inflammatory responses or environmental impact.

While traditionally, natural polymers were challenging to process into electrospun fibers due to their complex molecular structures, advancements in electrospinning technology have improved their viability. This has encouraged further research and development, expanding the range of applications for natural polymer-based electrospun fibers. Despite these advantages, natural polymers still have limitations such as higher costs and more variable mechanical properties compared to synthetics, which has kept their market share relatively smaller. However, with increasing regulatory pressures to adopt sustainable materials, this segment is expected to grow steadily.

End Use Insights

The medical & healthcare dominated the market with a revenue share of 32.8% in 2023. This is expected to grow at the highest CAGR of 12.3% from 2024 to 2030. This sector is the largest consumer of electrospun fibers, driven by their extensive use in applications such as wound dressings, drug delivery systems, tissue engineering, and medical implants. Electrospun fibers are increasingly used as scaffolds for tissue engineering due to their biocompatibility and ability to mimic the extracellular matrix, promoting cell growth and tissue regeneration.

Moreover, these are ideal for fabricating nanofibrous mats that can encapsulate drugs and provide controlled release, improving the efficiency of treatments. Additionally, in wound care, these nanofibers are utilized for wound dressings that promote faster healing and prevent infection. Their porous structure allows for controlled drug release, enhancing therapeutic outcomes.

Electrospun fibers are used in developing smart textiles, which include functional fabrics with enhanced capabilities such as conductivity, moisture control, and thermal regulation. Furthermore, the use of nanofibers in protective gear such as masks, gloves, and hazmat suits has surged, particularly due to the COVID-19 pandemic. Their fine structure can trap microorganisms and pollutants, offering superior filtration performance. The demand for high-performance textiles, such as in sportswear and fashion, along with increased awareness around protective clothing, is fueling growth.

Regional Insights

The North America electrospun fibers market dominated the industry with the highest revenue share of 38.1% in 2023. North America holds a significant share of the global electrospun fibers industry, primarily due to its advanced healthcare and biotechnology sectors, alongside strong demand from the defense, aerospace, and energy industries.

U.S. Electrospun Fibers Market Trends

The U.S. is a global leader in healthcare innovation, with heavy investment in medical devices, tissue engineering, and drug delivery systems. The widespread use of electrospun fibers in these applications, particularly in wound healing, drug encapsulation, and tissue scaffolding, drives demand. Moreover, the U.S. has a well-established defense and aerospace sector. Such fibers are used in lightweight composites and protective armor, which are crucial for reducing aircraft weight and improving the performance of military gear.

Europe Electrospun Fibers Market Trends

Europe is another major region for the electrospun fibers market, driven by stringent environmental regulations, strong healthcare infrastructure, and growing demand for advanced textiles and sustainable materials. Additionally, European nations are focusing heavily on environmental sustainability, which has increased the demand for eco-friendly materials, including biodegradable electrospun fibers used in packaging, water filtration, and pollution control.

Asia Pacific Electrospun Fibers Market Trends

The Asia Pacific region is witnessing the fastest growth in the electrospun fibers market due to rapid industrialization, growing demand in healthcare, and advancements in energy and filtration technologies. Countries like China, India, and Japan are investing heavily in their healthcare infrastructure, which drives demand for electrospun fibers in medical devices, wound care, and drug delivery systems. The increasing population and aging demographic in the region also contribute to this growth. Moreover, Asia Pacific is a global leader in textile manufacturing, and the adoption of electrospun fibers for functional textiles, such as moisture-wicking fabrics, antimicrobial textiles, and protective clothing, is growing rapidly.

Key Electrospun Fibers Company Insights

Some key players operating in the market include Donaldson Company, Inc., and FibeRio Technology Corporation

-

Donaldson Company, Inc., established in 1915, is involved in filtration technologies. The company serves a wide range of industries, including aerospace, agriculture, construction, and industrial manufacturing. The company integrates electrospun nanofibers into its advanced filtration media, such as its Tetratex® nanofiber technology, to improve filtration efficiency by capturing ultra-fine particles.

-

FibeRio Technology Corporation is an innovative player in the field of industrial-scale electrospun fiber production. Established in 2009, FibeRio has developed Forcespinning® technology, which allows the mass production of nanofibers at a lower cost compared to traditional electrospinning methods. This technology enables the scalable production of nanofibers for various applications, such as filtration, textiles, and medical devices.

Espin Technologies is one of the emerging market participants in the market.

- Espin Technologies is a growing company that focuses on producing nanofiber materials for the medical and filtration industries. The company is a specialist in electrospun nanofibers that are used in wound care, drug delivery systems, and high-performance filtration applications.

Key Electrospun Fibers Companies:

The following are the leading companies in the electrospun fibers market. These companies collectively hold the largest market share and dictate industry trends.

- Nanopharma

- NanoFiber Solutions

- Espin Technologies

- Revolution Fibres

- FibeRio Technology Corporation

- Elmarco

- Donaldson Company, Inc.

- Nippon Paper

Recent Developments

-

In August 2023, FibeRio Technology Corporation announced an expansion of its production capabilities with a new facility dedicated to scaling up its Forcespinning® technology. This expansion aims to increase their capacity to produce nanofibers for diverse applications, including filtration and energy storage. The new facility is expected to enhance its ability to meet growing demand and develop new product lines.

Electrospun Fibers Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 1.1 billion

Revenue forecast in 2030

USD 2.1 billion

Growth rate

CAGR of 11.7% from 2023 to 2030

Actual data

2018 - 2023

Forecast period

2024 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2024 to 2030

Report coverage

Revenue forecast, competitive landscape, growth factors, and trends

Segments covered

Material type, end use, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan;; Brazil; Saudi Arabia

Key companies profiled

Nanopharma; NanoFiber Solutions; Espin Technologies; Revolution Fibres; FibeRio Technology Corporation; Elmarco, Donaldson Company, Inc.; Nippon Paper

Customization scope

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Electrospun Fibers Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the segments from 2018 to 2030. For this study, Grand View Research has segmented the global electrospun fibers market report based on the material type, end use, and region:

-

Material Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Natural Polymers

-

Synthetic Polymers

-

Others

-

-

End Use Outlook (Revenue, USD Million, 2018 - 2030)

-

Medical & Healthcare

-

Textiles

-

Energy & Power

-

Automotive

-

Electronics & Semiconductor

-

Water Treatment

-

Aerospace & Defense

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

India

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Saudi Arabia

-

-

Frequently Asked Questions About This Report

b. The global electrospun fibers market size was estimated at USD 1,000.5 million in 2023 and is expected to reach USD 1,095.5 million in 2024.

b. The global electrospun fibers market is expected to grow at a compound annual growth rate (CAGR) of 11.7% from 2024 to 2030 to reach USD 2,133.2 million by 2030.

b. Among material, Synthetic Polymers accounted for the largest market in 2023 with a revenue share of 60.6% and the growing demand for synthetic polymers in applications such as drug delivery systems, wound healing, and filtration membranes is driving their market expansion..

b. Some key players operating in the electrospun fibers market include Nanopharma, NanoFiber Solutions, Espin Technologies, Revolution Fibres, FibeRio Technology Corporation, Elmarco, Donaldson Company, Inc., and Nippon Paper

b. The key factors that are driving the electrospun fibers market are its unique properties and versatility in applications.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.