- Home

- »

- Advanced Interior Materials

- »

-

Bearing Isolators Market Size, Share & Growth Report, 2030GVR Report cover

![Bearing Isolators Market Size, Share & Trends Report]()

Bearing Isolators Market (2025 - 2030) Size, Share & Trends Analysis Report By Material, By End Use (Oil & Gas, Chemical, Mining, Paper & Pulp, Metal Processing, Manufacturing), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-370-7

- Number of Report Pages: 109

- Format: PDF

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Segmentation

- Methodology

- Download FREE Sample

-

Download Sample Report

Bearing Isolators Market Size & Trends

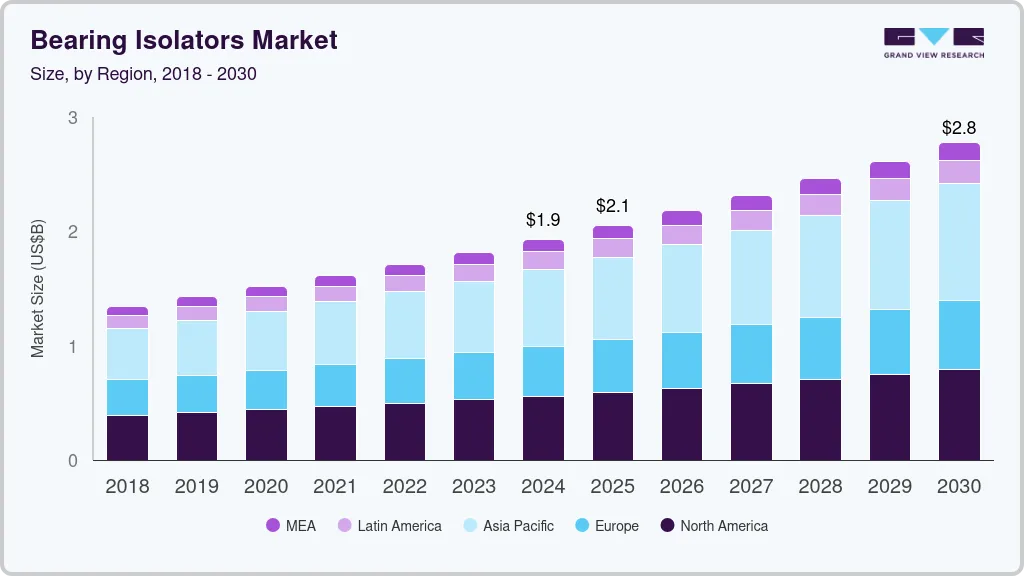

The global bearing isolators market size was estimated at USD 1,931.3 million in 2024 and is projected to grow at a CAGR of 6.2% from 2025 to 2030. This growth is attributed to the shift from reactive to proactive maintenance strategies which is increasing the demand for reliable sealing solutions like bearing isolators. By preventing premature equipment failures, this product support predictive maintenance practices, thereby optimizing maintenance schedules and reducing overall operational costs.

Industries across manufacturing, oil & gas, automotive, and others are prioritizing minimizing downtime and enhancing equipment reliability. This has increased the demand for bearing isolators as they offer superior protection against contamination and lubricant loss, thereby extending equipment life and reducing maintenance costs. In addition, stringent regulatory requirements regarding emissions, safety, and efficiency are pushing industries to adopt more effective sealing which contribute to improvement of environmental performance and operational safety. Thereby, driving product growth in the global market.

Ongoing advancements in materials, design, and manufacturing processes are enhancing the performance and reliability of bearing isolators. These innovations are expanding the application scope of this product in demanding environments such as high temperatures, corrosive chemicals, and abrasive particles. Furthermore, end users are increasingly focused on reducing maintenance costs, energy consumption, and downtime which is further driving market demand. Bearing isolators helps in improving equipment reliability and efficiency, thereby contributing to lower operational costs.

Initial cost of high-performance bearing isolators can act as a barrier to adoption of product. In addition, its compatibility with existing equipment and retrofitting challenges can hinder their adoption, especially in older machinery where modifications may be complex or costly.

The market is characterized by the presence of numerous suppliers and manufactures offering a wide range of products with varying quality and performance characteristics. In addition, collaborations between product manufacturers and industrial equipment OEMs can facilitate product development and market penetration, increasing competition in the market.

Material Insights

Based on material, the market is segmented into metallic and non-metallic materials. The metallic material segment led the market with the largest revenue share of 65.50% in 2023 and is further expected to grow at the fastest CAGR over forecast period. Metallic materials include stainless steel and bronze which are preferred for bearing isolators in applications involving high temperatures, where thermal stability and resistance to oxidation are crucial. In addition, they are well-suited for applications in harsh environments where exposure to moisture, chemicals, or abrasive particles is a concern. Stainless steel bearing isolators are known for their long service life and reliability.

The non-metallic bearing isolators are commonly made from high-performance polymers such as PTFE (Polytetrafluoroethylene) and UHMWPE (Ultra-High Molecular Weight Polyethylene). These materials offer excellent chemical resistance, low friction coefficients, and compatibility with various operating conditions. They are lightweight, non-corrosive, and can handle high speeds and temperatures, making them suitable for diverse industrial applications.

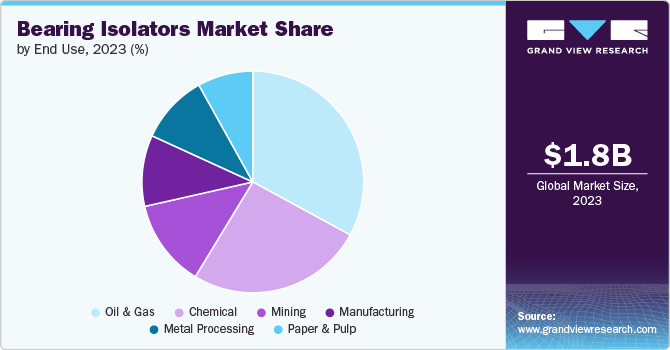

End Use Insights

Based on end use, the market is segmented into oil & gas, chemical, mining, paper & pulp, metal processing, and manufacturing. The oil & gas segment led the market with the largest revenue share of 33.0% in 2023 and is further expected to grow at the fastest CAGR over forecast period. This product is utilized in oil & gas industry for sealing rotating equipment such as pumps, compressors, and turbines. These components operate in demanding environments with high pressures, temperatures, and exposure to abrasive contaminants like sand and drilling fluids, which makes bearing isolators an ideal option.

Facilities in chemical sector handle corrosive chemicals, acids, solvents, and high temperatures, requiring robust sealing solutions to prevent leakage and contamination of process fluids. Thereby, this product plays a critical role in sealing pumps, mixers, agitators, and other rotating equipment in chemical processing plants. Moreover, in metal processing plants metallic isolators offer durability and resistance to mechanical wear, while non-metallic materials provide flexibility, chemical resistance, and effective sealing performance.

Regional Insights

The bearing isolators market in North America is expected to grow at a significant CAGR over the forecast period. This demand is supported by presence of environmental regulations and workplace safety standards in North America that necessitates use of reliable sealing solutions to prevent leaks and minimize environmental impact.

U.S. Bearing Isolators Market Trends

The bearing isolators market in the U.S. is anticipated to grow at the fastest CAGR of 5.1% over the forecast period. The U.S. is home to a significant industrial base across sectors such as manufacturing, oil & gas, automotive, and mining. The need to enhance equipment reliability and minimize maintenance costs is driving the adoption of advanced sealing solutions such bearing isolators in country.

Asia Pacific Bearing Isolators Market Trends

Asia Pacific dominated the bearing isolators market with the revenue share of 34.36% in 2023 and is further expected to grow at a fastest CAGR over forecast period. Countries in Asia Pacific are investing in advanced manufacturing technologies to enhance productivity and quality. This is increasing demand for product as it contributes to this effort by reducing downtime and improving operational efficiency in manufacturing facilities. In addition, region’s growing automotive and electronic industries is a key driver for bearing isolator demand as they utilize the product in applications such as assembly lines, machining centers, and automated production equipment.

Europe Bearing Isolators Market Trends

The bearing isolators market in Europe is expected to grow at the fastest CAGR during the forecast period. Industries in Europe are increasingly focusing on automation and efficiency to remain competitive globally. The product plays a crucial role in ensuring the reliability and uptime of automated manufacturing processes, thereby driving demand. In addition, need to upgrade existing machinery with modern sealing solutions is also driving market for product in Europe.

Key Bearing Isolators Company Insights

Some of the key players operating in the market AESSEAL, Flowserve Corporation and Garlock Sealing Technologies:

-

Flowserve Corporation, founded in 1997 and headquartered in Irving, Texas, USA, is a manufacturers of fluid motion and control products and services. The company specializes in designing, manufacturing, and servicing of pumps, valves, seals, and related equipment for various industrial applications

-

AESSEAL, a UK based company was established in 1979 and is a manufacturer of mechanical seals, bearing protectors, and sealing systems. Furthermore, it has operations in over 104 countries and extensive network of sales offices

Isomag Corporation and Inpro/Seal are some of the emerging participants in the market.

-

Isomag Corporation specializes in the design and manufacture of magnetic bearing seals and bearing isolators. Founded in 1985 and based in U.S., company serves diverse industries including oil & gas, chemical processing, food & beverage, and power generation

-

Inpro/Seal is headquartered in Illinois, U.S. and is founded in 1977. It is a leading manufacturer of bearing isolators and air sealing solutions. Furthermore, Inpro/Seal's products are utilized across various industries including manufacturing, chemical processing, mining, and power generation

Key Bearing Isolators Companies:

The following are the leading companies in the bearing isolators market. These companies collectively hold the largest market share and dictate industry trends.

- Timken Company

- AESSEAL

- Flowserve Corporation

- Parker Hannifin Corporation

- John Crane

- Garlock Sealing Technologies

- Baldor Electric Company

- Advanced Sealing International

- Isomag Corporation

- Inpro/Seal

Recent Developments

- In August 2022,Inpro/Seal launched its new product magnetic bearing isolator named VBMag. This product will find application in challenging situations such as high oil splash, oil mist, and flood. Furthermore, it uses magnetic force in order to create seal and provide protection against contamination ingress and lubrication loss

Bearing Isolators Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 2,051.8 million

Revenue forecast in 2030

USD 2,777.0 million

Growth rate

CAGR of 6.2% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2030

Report coverage

Revenue forecast, competitive landscape, growth factors, and trends

Segments covered

Material, end use, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan; South Korea; Brazil; Argentina

Key companies profiled

Timken Company; AESSEAL; Flowserve Corporation; Parker Hannifin Corporation; John Crane; Garlock Sealing Technologies; Baldor Electric Company; Advanced Sealing International; Isomag Corporation; Inpro/Seal

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Bearing Isolators Market Report Segmentation

This report forecasts revenue growth at regional & country levels and provides an analysis of the industry trends in each of the segments from 2018 to 2030. For this study, Grand View Research has segmented the global bearing isolators market report based on material, end use, and region:

-

Material Outlook (Revenue, USD Million; 2018 - 2030)

-

Metallic

-

Non-metallic

-

-

End Use Outlook (Revenue, USD Million; 2018 - 2030)

-

Oil & Gas

-

Chemical

-

Mining

-

Paper & Pulp

-

Metal Processing

-

Manufacturing

-

-

Regional Outlook (Revenue, USD Million; 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global bearing isolators market is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030 to reach USD 2.78 billion by 2030.

b. Oil & gas end use accounted for largest revenue share of 33% in 2023 and is further expected to grow at a fastest rate over forecast period. This product is utilized in oil & gas industry for sealing rotating equipment such as pumps, compressors, and turbines.

b. Some key players operating in the bearing isolators market include Timken Company, AESSEAL, Flowserve Corporation, Parker Hannifin Corporation, John Crane, Garlock Sealing Technologies, Baldor Electric Company, Advanced Sealing International, Isomag Corporation, Inpro/Seal

b. The key factors that are driving the bearing isolators market growth is the shift from reactive to proactive maintenance strategies which is increasing the demand for reliable sealing solutions like bearing isolators.

b. The global bearing isolators market size was estimated at USD 1.82 billion in 2023 and is expected to reach USD 1.93 billion in 2024.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.