Disposable Syringes Market: Increase In Blood Donation Volumes Calls For High Demand Of Disposable Syringes

Use of sterilizable syringes and needles in undeveloped countries is one of the key causes for transmission of HIV and Hepatitis B. It also requires additional costs for maintenance, which adds to the government’s expenditure amidst scarce resources. As a result, governments of different countries are shifting to non-sterilizable ones, thus boosting the demand for the same.

Disposable syringe market players recognize Africa as an attractive market as it has high prevalence of infectious diseases and does not have established production facilities. China and European countries are the main exporters to the African continent. Companies such as Jiangsu Jichun Medical Devices have Africa as their key market for infusion set and export 50% of their products for European, African, and Middle Eastern markets.

Companies in the U.S. file tenders to gain contracts to supply fixed or continuous amount of disposable syringes to African countries. For instance, Retractable Technologies supply their product Vanish Point to countries such as Botswana, Nigeria, Kenya, Ethiopia, and Cote d’Ivoire. Industry giants such as B Braun also have a strong presence in this region with more than 600 employees.

Accidental needlestick injuries are responsible for 33,800 HIV infections, 315,000 hepatitis C transmissions, and 1.7 million hepatitis B infections per year globally. Unsafe practices such as multiple uses of a syringe and needle and no precautionary measures undertaken by healthcare practitioners lead to needlestick injuries posing a threat to public health. Conventional disposable syringes provide protection to the recipient, but do not assure the safety of healthcare practitioners.

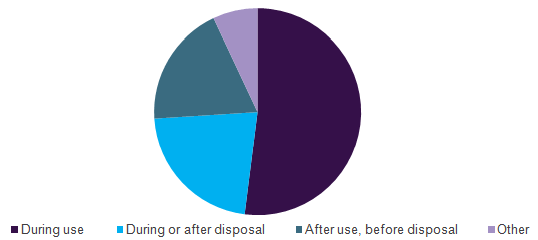

Percentage of event of needle stick injuries, 2015

New product development is the key to cater to the growing demand. Industry players are in a constant process of innovating and are introducing new techniques to make the disposable syringes manufacturing process cost effective and efficient. Companies such as Zahoransky Automation & Molds and ENGEL offer innovative systems for molding and packaging. In October 2013, it demonstrated a fully automated system to manufacture glue-less disposable syringes. The system was capable of carrying out procedures from making moulds to blister free packaging. It was equipped to produce 400 units per minute which add up to 52 million syringes in a year. Moreover, in February 2012, ENGEL developed an integrated production unit which was claimed to reduce cost.

In-depth report on global disposable syringes market by Grand View Research:

In-depth report on global disposable syringes market by Grand View Research:

https://www.grandviewresearch.com/industry-analysis/disposable-syringes-market