- Home

- »

- Advanced Interior Materials

- »

-

White Cement Market Size, Share And Trends Report, 2030GVR Report cover

![White Cement Market Size, Share & Trends Report]()

White Cement Market (2025 - 2030) Size, Share & Trends Analysis Report By Product (While Portland Cement, While Masonry Cement), By Application (Residential, Commercial), By Region, And Segment Forecasts

- Report ID: GVR-4-68040-145-1

- Number of Report Pages: 80

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

- Report Summary

- Table of Contents

- Interactive Charts

- Methodology

- Download FREE Sample

-

Download Sample Report

White Cement Market Summary

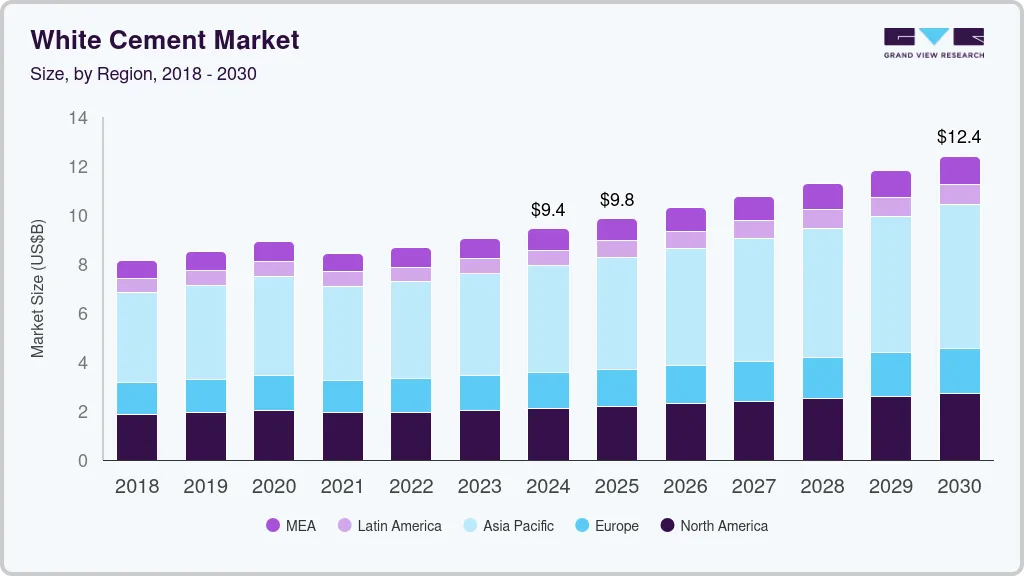

The global white cement market size was estimated at USD 9.43 billion in 2024 and is projected to reach USD 12.39 billion by 2030, growing at a CAGR of 4.7% from 2025 to 2030. The market growth is due to growing construction expenditures of economies around the globe.

Key Market Trends & Insights

- Asia Pacific dominated the market with the largest revenue share of 46.1% in 2024.

- The white cement market in U.S. is anticipated to grow at the fastest CAGR during the forecast period.

- In terms of product, the white portland cement segment led the market with the largest revenue share of 52.9% in 2024.

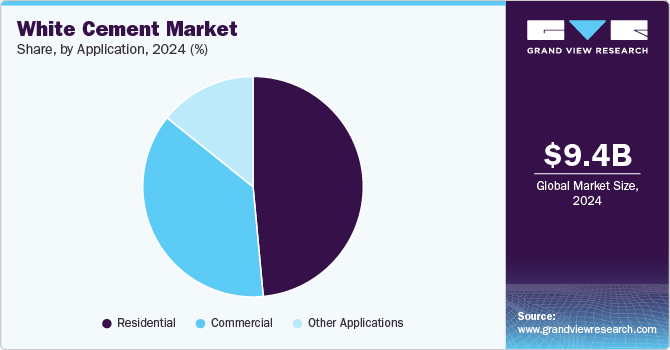

- In terms of application, the residential segment led the market with the largest revenue share of 48.52% in 2024.

Market Size & Forecast

- 2024 Market Size: USD 9.43 Billion

- 2030 Projected Market Size: USD 12.39 Billion

- CAGR (2025-2030): 4.7%

- Asia Pacific: Largest market in 2024

One of the key factors drivers for market growth is the strong development of the industrial sector in developing economies such as India, Mexico, and Brazil after the recovery from the COVID-19 pandemic. As a result, the overall industry is expected to grow over the forecast period. The value-added features such as heat reflection and increased aesthetic appeal have led to white cement often being employed as an alternative to grey cement. The product demand is higher in countries with warmer climates owing to the resulting white concrete surface which reflects more heat than regular grey concrete. Furthermore, it is a commonly available concrete element that is effective well in a variety of applications as it improves the aesthetics and performance of pavements, buildings, and other structures.The market in the U.S. has witnessed higher growth in recent years due to increasing product demand by ongoing commercial and residential construction projects. According to the n 2022, commercial construction spending in the U.S. was around USD 97.00 billion, while single-family residential building spending was USD 404.00 billion. In addition, the multifamily residential construction spending in the U.S. was USD 119.00 billion in 2022, with a forecasted spending of USD 123.00 billion by the end of 2023, which is a 4% increase in construction spending. The value chain of the market comprises raw material suppliers, manufacturers, distributors, and end users. Companies operating as raw material suppliers are involved in providing various machinery, tools, limestone, and additives to the manufacturers. The manufacturers then are involved in griding, processing, and finishing the raw materials to produce white cement.

White cement is made from non-iron raw materials including China clay and white limestone, as well as materials with low levels of coloring components like Fe, Mn, Cr, and Ti. Furthermore, as white cement is produced in a separate kiln, it is more costly than standard Portland cement. The whiteness content of white cement is its most essential feature. It is also available in 325, 400, and 475 strength classifications.

The applications of white cement are majorly based on the factors involving the construction practices in the country, purchasing power of the people, GDP of the country, and campaigns by the manufacturers and other stakeholders to raise awareness of new uses of white cement in construction. The primary applications of white cement in residential construction are in repair works, tile installation, and prefabricated items owing to their quality, usage, aesthetics, and product range.

Developing countries such as India, China, Mexico, Brazil, and Indonesia are expected to generate staggering demand for the product over the coming years, owing to the presence of major manufacturers in these countries. For instance, UltraTech Cement Ltd. is India's largest producer of white cement, grey cement, and RMC (white concrete). It has operations in the UAE, India, Bahrain, Bangladesh, and Sri Lanka. It is also India's largest cement exporter, extending out to countries in the Middle East. The company sells white cement under the brand name Birla White in the Indian market and has a manufacturing plant with a capacity of 0.68 metric tonnes per annum (MTPA).

Product Insights

The white portland cement segment led the market with the largest revenue share of 52.9% in 2024. White Portland cement, as the name suggests, is a kind of cement that is white. Except for the color and fineness, it is identical to standard grey Portland cement.The segment is expected to grow over the forecast period as it is made from iron oxide and manganese oxide, making them ideal for applications such as designer flooring, paver tiles, concrete walls, grit wash walls, and tyrolean walls.

The use of white cement for architectural and decorative concrete has the benefit of providing a neutral tinting foundation and uniform color results. It is available in every color, from pure whites to vibrant and pastel hues. White cement is prepared in accordance with the American Society for Testing and Materials (ASTM International) C 150 standard called ‘Portland Cement Specification’. The most widespread are Types I and III, but Types II and V are also manufactured.

The white masonry cement segment is expected to grow at a significant CAGR over the forecast period, as they are designed to be used instantly at the construction site. White masonry cement yields reliable workability improves board life and provides a more cohesive mix. There are two main types of white masonry cement, namely, Type N and Type S. Type N is majorly used for normal masonry construction, whereas Type S is used in masonry structures that require more than double the strength of a Type N.

Application Insights

Based on application, the residential segment led the market with the largest revenue share of 48.52% in 2024. The residential segment is inclusive of residential buildings, apartments, complexes, and small houses. White cement is majorly used in residential applications on account of its high compressive strength, low alkali content, and aesthetic looks. The growing housing sector in emerging economies such as India is expected to trigger the product demand owing to their high usage in used in cast-in-situ floorings, marble/tile laying, mosaic tile manufacturing, wall finishes, whitewashing, and repair work.

The favorable growth of the residential sector in emerging markets, including Turkey, South Africa, India, China, and Middle East countries, on account of the easy availability of home loans is expected to have a strong impact on market growth over the next seven years. In addition, innovation in product varieties using advanced technology and hassle-free installation is projected to drive the market growth from the residential application segment over the forecast period.

The commercial segment is expected to grow at a notable CAGR over the forecast period, owing to the rising demand for highly durable and cost-efficient cement for use in high-traffic commercial sectors. The development of new products such as RMC, dry mix mortars (various ready-to-use products), and stamped concrete has considerably driven the market growth. In addition, white cement is emerging as cost cost-effective solution used in various sectors, including healthcare, office, institution, retail, and other commercial areas owing to an increase in understanding of architectural concepts of the end-users.

The other segment include industrial and infrastructural applications, which are increasing due to their rising preference by designers and architects. Moreover, the expansion of modern manufacturing plants, factories, warehouses, and rapid industrialization in developing economies are expected to propel market growth over the forecast period.

Regional Insights

The white cement market in North America is expected to witness at a significant CAGR over the forecast period, on account of the increasing construction of residential and commercial buildings in the region. The market is witnessing a rapid shift toward the domestic production of white cement, which is backed by the growing demand from flooring and walling applications. The need for the upgradation of existing buildings and structures in the region is expected to augment the demand for white cement in both residential and commercial constructions.

U.S. White Cement Market Trends

The white cement market in U.S. is anticipated to grow at the fastest CAGR during the forecast period. In the United States specifically, white cement demand is on the rise as part of a broader trend toward premium construction materials. High-profile projects, luxury developments, and government buildings often use white cement to achieve a high-end, polished look. The demand for white cement in decorative applications-like polished floors, precast concrete panels, and detailed finishes-is significant, as it allows designers to create bright, appealing spaces. The U.S. market also emphasizes sustainability, with a push toward materials that align with energy-efficient and environmentally conscious standards. White cement reflects more light, helping reduce energy usage in buildings, which appeals to both commercial developers and residential builders aiming for energy-saving benefits. This environmental benefit complements the U.S. interest in green building certifications, such as LEED, further driving the adoption of white cement across the country.

Asia Pacific White Cement Market Trends

Asia Pacific dominated the market with the largest revenue share of 46.1% in 2024 and is expected to continue its dominance over the forecast period. High product demand from residential and non-residential construction segments in emerging economies of Asia Pacific, including China and India is expected to provide growth opportunities for the market. The product has majorly penetrated the regional construction sector owing to the widespread availability of prominent manufacturers such as UltraTech Cement Ltd., Shree Cement Limited, and, Ambuja Cements Limited.

The white cement market in China has surged the demand due to rapid urbanization and extensive infrastructure projects that call for premium construction materials. White cement is preferred for its ability to produce visually striking, durable structures, fitting well with China’s focus on high-quality, long-lasting buildings. Beyond practical uses, white cement aligns with cultural preferences in China, where it’s seen as a premium product that conveys a clean and high-status aesthetic, making it highly desirable for upscale projects.

Europe White Cement Market Trends

The white cement market in Europe is closely tied to architectural trends that prioritize aesthetics, clean lines, and minimalist designs. In both residential and commercial construction, white cement is often selected for creating bright, modern spaces that align with the current design trends. In historical restoration projects, too, white cement is valued for matching older materials, blending with existing structures while enhancing durability.

Central & South America White Cement Market Trends

The white cement market in Central & South America is anticipated to witness at a substantial CAGR during the forecast period, on account of the flourishing construction industry. Emerging economies, such as Argentina, Brazil, and Peru, are witnessing population growth coupled with rapid urbanization. These factors are triggering the construction of commercial units in Central & South America, thereby fueling the product demand in the region.

Key White Cement Company Insights

Some key players operating in the market include Cementir Holding NV and J.K. Cement Company:

-

Cementir Holding NV, an Italian multinational, is a global leader in the production and distribution of white cement, known for its high quality and wide range of applications. With over 70 years in the industry, the company has a diversified portfolio that includes cement, ready-mixed concrete, aggregates, and other building materials. Cementir has operations in over 18 countries, which allows it to maintain a substantial global footprint.

-

UltraTech Cement, part of the Aditya Birla Group, is a major cement manufacturer in India and has a growing presence in the white cement segment. Although known primarily for its gray cement products, UltraTech has been expanding its white cement offerings, recognizing the growing demand for high-quality, aesthetic construction materials in India and abroad. The company’s entry into white cement marks a significant expansion into this niche segment.

Some of the emerging players in the market include:

-

J.K. Cement, based in India, is one of the largest producers of white cement in the country and has also established a significant presence internationally. Founded in 1975, J.K. Cement operates several manufacturing plants and has made substantial investments to increase its production capacity. The company is particularly known for its white cement brand, J.K. White Cement, which is widely used in high-end architectural applications.

Key White Cement Companies:

The following are the leading companies in the white cement market. These companies collectively hold the largest market share and dictate industry trends.

- Cementir Holding N.V.

- Çimsa Çimento Sanayi ve Ticaret A.Ş

- Royal White Cement

- LafargeHolcim

- Aditya Birla (Grasim Industries Limited)

- Cimsa

- Dyckerhoff GMBH

- Federal White Cement

- India Cements Ltd

- J.K. Cement Company

- Ultratech Cement Ltd

- Saudi White Cement Company

Recent Developments

-

In 2022, UltraTech Cement, a subsidiary of Aditya Birla Group, inaugurated a state-of-the-art putty plant in Rajasthan with an annual capacity of 400,000 metric tons. This facility is dedicated to producing UltraTech's renowned WallCare brand of white cement-based putty

-

In 2022, Cementir Holding introduced its innovative Futurecem limestone calcined clay cement into the Benelux and French cement markets. This groundbreaking cement leverages Cementir Holding's patented processes to replace over 35% of clinker in cement with limestone and calcined clay. This substitution not only maintains the cement's strength and quality but also significantly reduces its carbon footprint by approximately 30% compared to ordinary Portland cement (OPC)

White Cement Market Report Scope

Report Attribute

Details

Market size value in 2025

USD 9.85 billion

Revenue forecast in 2030

USD 12.39 billion

Growth rate

CAGR of 4.7% from 2025 to 2030

Base year for estimation

2024

Historical data

2018 - 2023

Forecast period

2025 - 2030

Quantitative units

Revenue in USD million/billion and CAGR from 2025 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan; Australia; Brazil; Argentina

Segments covered

Product, application, region

Key companies profiled

Cementir Holding N.V.; Çimsa Çimento Sanayi ve Ticaret A.Ş; Royal White Cement; LafargeHolcim; Aditya Birla (Grasim Industries Limited); Cimsa; Dyckerhoff GMBH; Federal White Cement; India Cements Ltd; J.K. Cement Company; Ultratech Cement Ltd; Saudi White Cement Company

Customization scope

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global White Cement Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis on the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global white cement market report based on the product, application, and region:

-

Product Outlook (Revenue, USD Million, 2018 - 2030)

-

While Portland Cement

-

While Masonry Cement

-

Others

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Residential

-

Commercial

-

Other Applications

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

India

-

Australia

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. Some of the key players operating in the white cement market include Cementir Holding N.V., Çimsa Çimento Sanayi ve Ticaret A.Ş, Royal White Cement, LafargeHolcim, Aditya Birla (Grasim Industries Limited), and Cimsa.

b. The key factors driving the white cement market are the growing construction expenditures of economies around the globe and the rise in industrial and commercial activities.

b. The global white cement market size was estimated at USD 9.43 billion in 2024 and is expected to reach USD 9.85 billion in 2025.

b. The global white cement market is expected to grow at a compound annual growth rate of 4.7% from 2025 to 2030 to reach USD 12.39 billion by 2030.

b. Among products, white Portland cement dominated the white cement market with approximately 52.9% share in 2024 owing to their versitality, durability, and enhanced aesthetics.

Share this report with your colleague or friend.

Need a Tailored Report?

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

ISO 9001:2015 & 27001:2022 Certified

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

Trusted market insights - try a free sample

See how our reports are structured and why industry leaders rely on Grand View Research. Get a free sample or ask us to tailor this report to your needs.