Web Coating Equipment Market Size, Share & Trends Analysis Report By Type (Roll-to-roll Coating, Slot-die Coating, Spray Coating), By Application (Flexible Electronics, Packaging), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-435-7

- Number of Report Pages: 152

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

Web Coating Equipment Market Trends

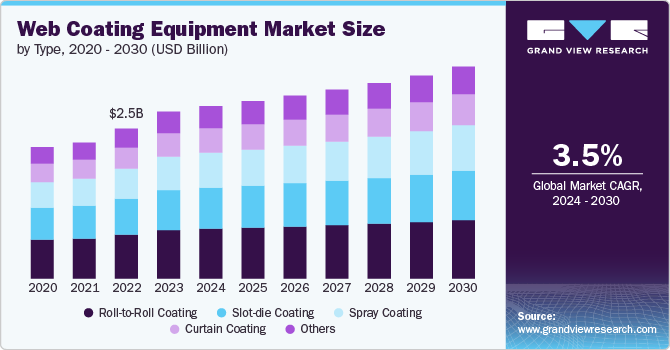

The global web coating equipment market size was estimated at USD 2,821.0 million in 2023 and is projected to grow at a CAGR of 3.5% from 2024 to 2030. The market is currently experiencing robust growth, attributed largely to several key factors. First, the ever-increasing demand for consumer electronics has propelled the need for more advanced web coating technologies. These are essential in producing screens and other components where precision and durability are paramount. Second, the push for sustainability and energy efficiency in various industries has increased the adoption of web-coated products. These products, often used in packaging, automotive, and solar panel sectors, offer enhanced performance while reducing environmental impact.

Furthermore, technological advancements in coating processes have significantly improved the efficiency and capability of web coating equipment. Innovations such as atomic layer deposition (ALD) and chemical vapor deposition (CVD) have enabled manufacturers to produce high-quality coatings with better control and at lower costs. Lastly, the expansion of the pharmaceutical and food packaging industries, which require high standards for safety and hygiene, has also contributed to the growth of the market. In these sectors, web coating technologies are crucial for ensuring product integrity and shelf life, driving further investment into web coating solutions.

Web coating equipment plays a crucial role in various manufacturing processes, particularly in industries such as packaging, electronics, printing, and energy. For instance, in the production of flexible packaging, web coating equipment is used to apply barrier coatings to protect against moisture and oxygen. In the electronics industry, it is employed to deposit conductive materials for circuits or touch screens.

Drivers, Opportunities & Restraints

The market for web coating equipment is driven primarily by the increasing demand for high-quality coated materials across various sectors, such as packaging, electronics, and automotive industries. This surge is attributed to the need for products with enhanced properties, including moisture barrier, thermal insulation, and electrical conductivity. In addition, the growth in flexible packaging due to its convenience and sustainability benefits has propelled the demand for advanced web coating technologies. Technological innovations in coating processes that offer higher efficiency and precision also play a significant role in driving the market forward.

There are significant opportunities in the development and adoption of eco-friendly and energy-efficient coating processes. As industries continue to focus on reducing their environmental footprint, web coating equipment manufacturers have the chance to innovate and offer solutions that minimize solvent use and energy consumption. The burgeoning markets of solar energy and flexible electronics also present lucrative opportunities for the expansion of the market, catering to the demand for high-performance coatings that can enhance the durability and efficiency of solar panels and wearable devices.

The market faces restraints, including the high initial investment costs for web coating equipment, which can inhibit the entry of new players and limit the adoption among small and medium-sized enterprises. Moreover, stringent environmental regulations related to the emission of volatile organic compounds (VOCs) from certain coating processes can also pose challenges.

Type Insights

“The demand for spray coating segment is expected to grow at a CAGR of 4.4% from 2024 to 2030 in terms of revenue”

The roll-to-roll coating segment led the market and accounted for 29.1% of the global revenue share in 2023. The roll-to-roll coating segment is experiencing significant growth, driven by the increasing demand in sectors such as electronics, energy storage, and flexible packaging. This growth is fueled by the advantages of roll-to-roll processes, including efficiency, cost-effectiveness, and the ability to facilitate continuous high-volume production. Innovations in material science and coating technologies further bolster this segment's growth, catering to the increasing need for advanced and flexible substrates in various applications.

Spray coating is gaining traction as a technique due to its versatility and adaptability across a wide range of applications, from thin-film electronics to protective coatings. This method is particularly valued for its ability to provide uniform coatings over large areas with speed and efficiency. Innovations in spray technology, such as precision control systems and advanced nozzle designs, have enhanced the capability to deposit materials with high uniformity and at lower temperatures, making them suitable for sensitive substrates.

Application Insights

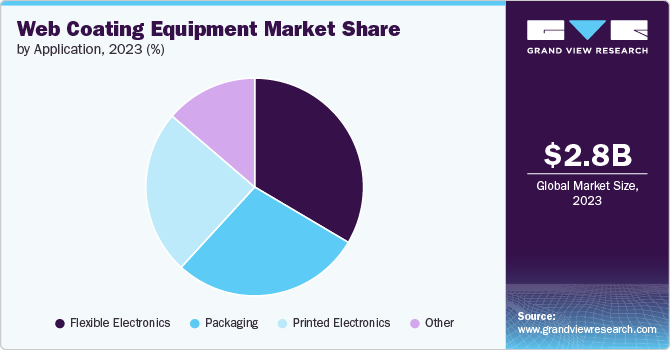

“The demand from printed electronics application segment is expected to grow at a significant CAGR of 4.1% from 2024 to 2030 in terms of revenue”

The flexible electronics segment accounted for 33.5% of the global revenue share in 2023. The flexible electronics segment is driven by the increasing demand for wearable devices, foldable displays, and flexible sensors. This surge is primarily due to the unique attributes of flexible electronics, such as their lightweight, bendability, and durability, which open up new possibilities for consumer electronics, healthcare, and automotive industries, among others. The development of sophisticated web coating technologies, capable of depositing thin, uniform layers on flexible substrates, is critical to this segment. These advancements ensure the functional integrity and performance of flexible electronic devices while enabling mass production. As the market for flexible electronics continues to expand, so does the need for innovative web coating solutions, making it a highly dynamic and promising area within the web coating equipment industry.

The printed electronics segment is anticipated to experience substantial growth over the forecast period. This growth is propelled by the rising demand for lightweight, flexible, and cost-effective electronics. This segment leverages advanced printing and coating techniques to fabricate electronic devices on various substrates, enabling the mass production of components such as RFID tags, OLED displays, and solar cells.

Regional Insights

The North America web coating equipment market is experiencing steady growth, underpinned by the region's advanced manufacturing sector, technological leadership, and high demand for coated products across various industries, including electronics, packaging, and automotive. Significant investments in research and development, coupled with a strong emphasis on innovation and quality, are driving the adoption of new and improved web coating technologies.

Asia Pacific Web Coating Equipment Market Trends

“China to witness fastest market growth at 4.6% CAGR”

The Asia Pacific web coating equipment market holds a significant global share, driven by robust industrial growth, especially in countries such as China, Japan, South Korea, and India. The demand for web coating equipment in the Asia Pacific is further fueled by the expanding automotive, packaging, and solar energy sectors, which rely heavily on coated materials for enhanced performance and durability.

The web coating equipment market in China is estimated to grow at a significant CAGR of 4.6% over the forecast period. This growth is primarily driven by the country's expanding electronics sector, robust manufacturing industry, and increasing investments in renewable energy, particularly solar panels, which require sophisticated coating technologies. China's focus on upgrading its industrial capabilities and enhancing product quality to meet both domestic and international demand is further fuelling market growth for web coating equipment.

Europe Web Coating Equipment Market Trends

The web coating equipment market in Europe is showing robust growth, buoyed by the region's strong emphasis on innovation, sustainability, and high-quality manufacturing standards. Europe's advanced industrial base, with a significant focus on the automotive, electronics, and packaging sectors, is driving the demand for cutting-edge web coating technologies that offer precision, efficiency, and environmental benefits.

Key Web Coating Equipment Company Insights

Some of the key players operating in the market include HanGlory Group, Dürr Systems AG, and Comexi.

-

HanGlory Group specializes in the manufacture and distribution of a wide range of industrial machinery and equipment, with a particular focus on web coating and laminating equipment. Company product portfolio encompasses advanced solutions for coating, laminating, and drying processes, designed to meet the stringent requirements of modern manufacturing operations.

-

Comexi is a globally renowned company in the manufacturing of machinery for the flexible packaging industry. Comexi specializes in the design, production, and distribution of high-tech solutions, including flexographic printing presses, laminators, slitters, and rewinders, among others.

Key Web Coating Equipment Companies:

The following are the leading companies in the web coating equipment market. These companies collectively hold the largest market share and dictate industry trends.

- HanGlory Group

- Dürr Systems AG

- Comexi

- Lamina System AB

- Meyer Burger

- Davis-Standard, LLC

- Kampf Schneid

- Glenro Inc.

- Ferag AG

- Faustel

- KROENERT GmbH & Co KG

- Bobst

- Applied Materials, Inc.

Recent Developments:

-

In June 2023, Applied Materials India teamed up with the Indian Institute of Technology Ropar (IIT Ropar) to create a Centre of Excellence in Thermal Spray Coatings, aiming to pioneer advancements in surface engineering. This strategic collaboration is designed to foster innovation in thermal spray coating technologies, which are critical for enhancing the performance and longevity of materials across various industrial applications, including energy, aerospace, and automotive sectors.

Web Coating Equipment Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 2,913.8 million |

|

Revenue forecast in 2030 |

USD 3,580.5 million |

|

Growth Rate |

CAGR of 3.5% from 2024 to 2030 |

|

Base year for estimation |

2023 |

|

Historical data |

2018 - 2022 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

|

Segments covered |

Type, application, region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Country Scope |

U.S., Canada, Mexico, Germany, France, Italy, UK, Spain, China, Japan, India, South Korea, Australia, Brazil, Argentina, South Africa, Saudi Arabia, UAE |

|

Key companies profiled |

HanGlory Group, Dürr Systems AG, Comexi, Lamina System AB, Meyer Burger, Davis-Standard, LLC, Kampf Schneid, Glenro Inc., Ferag AG, Faustel, KROENERT GmbH & Co KG, Bobst, Applied Materials, Inc.. |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Web Coating Equipment Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global web coating equipment market based on type, application, and region:

-

Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Roll-to-Roll Coating

-

Slot-die Coating

-

Spray Coating

-

Curtain Coating

-

Others

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Flexible Electronics

-

Packaging

-

Printed Electronics

-

Other

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

Japan

-

China

-

India

-

Australia

-

South Korea

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global web coating equipment market size was estimated at USD 2,821.0 million in 2023 and is expected to reach USD 2,913.8 million in 2024.

b. The global web coating equipment market, in terms of revenue, is expected to grow at a compound annual growth rate of 3.5% from 2024 to 2030 to reach USD 3,580.5 million by 2030.

b. Asia Pacific dominated the web coating equipment market with a revenue share of 47.5% in 2023. TThe demand for web coating equipment in Asia Pacific is further fueled by the expanding automotive, packaging, and solar energy sectors, which rely heavily on coated materials for enhanced performance and durability.

b. Some of the key players operating in the web coating equipment market include HanGlory Group, Dürr Systems AG, Comexi, Lamina System AB, Meyer Burger, Davis-Standard, LLC, Kampf Schneid, Glenro Inc., Ferag AG, Faustel, KROENERT GmbH & Co KG, Bobst, Applied Materials, Inc.

b. The web coating equipment market is driven primarily by the increasing demand for high-quality coated materials across various sectors, such as packaging, electronics, and automotive industries. This surge is attributed to the need for products with enhanced properties, including moisture barrier, thermal insulation, and electrical conductivity. Additionally, the growth in flexible packaging due to its convenience and sustainability benefits has propelled the demand for advanced web coating technologies.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."