- Home

- »

- Advanced Interior Materials

- »

-

Textile Felt Market Size, Share And Growth Report, 2030GVR Report cover

![Textile Felt Market Size, Share & Trends Report]()

Textile Felt Market Size, Share & Trends Analysis Report By Raw Material (Natural Raw Material, Synthetic Raw Material), By Application (Footwear, Rugs, Clothing, Craft Projects, Tents), By Region, And Segment Forecasts, 2023 To 2030

- Report ID: GVR455973

- Number of Report Pages: 70

- Format: PDF, Horizon Databook

- Historical Data: ---

- Forecast Period: 1 - 2030

- Industry: Advanced Materials

Textile Felt Market Size & Trends

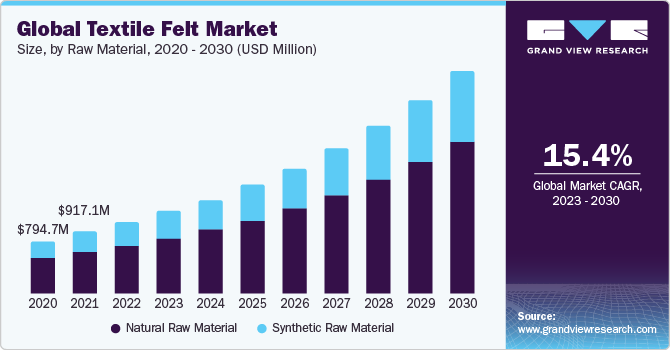

The global textile felt market was valued at USD 917.1 million in 2022 and is expected to grow at a CAGR of 15.4% over the forecast period. The biodegradable nature of the product is increasing its appeal among consumers who prioritize sustainability and eco-friendly materials. As awareness of environmental issues grows, there is a rising demand for organic and biodegradable goods, including textile felt. Furthermore, technological advancements and innovations in the textile industry have led to the development of new applications for the product. It is used in various industries such as automotive, electronics, and industrial applications for its thermal resistance, insulation properties, and sound absorption capabilities. The demand for thermal resistant materials and energy storage solutions has further fueled the growth of the product market.

Textile felt, a versatile and time-honored material, is created through the age-old process of felting, where fibers are meticulously compressed and entangled, resulting in a dense, non-woven fabric. This fabric can be crafted from various fibers, with traditional choices like wool celebrated for their natural resilience and insulating properties. It finds its place in a myriad of applications, from clothing, hats, and footwear where its insulating and moisture-wicking qualities shine, to creative fashion and interior design projects. Beyond aesthetics, felt serves practical functions in industries such as automotive and construction, offering exceptional soundproofing and insulation capabilities. Natural fiber-based felts are also garnering attention for their sustainability, as eco-conscious consumers seek biodegradable and renewable alternatives.

Raw Material Insights

Based on the raw material, the product market is segmented into natural and synthetic raw materials. The natural raw materials include wool, animal fur, and others whereas the synthetic raw materials include polyester, acrylic, rayon, and viscose blend. The natural raw material segment held the largest market share in 2022. The demand for natural raw materials is experiencing notable growth due to growing global emphasis on sustainability and environmental consciousness. Consumers and industries are increasingly seeking eco-friendly alternatives, and natural fibers align with these sustainability goals. They are biodegradable, renewable, and often have a lower carbon footprint than their synthetic counterparts, addressing concerns about the environmental impact of textile production.

Moreover, the qualities of natural fibers such as wool, cotton, silk, and bamboo, among others, make them highly attractive for textile felt production. These materials offer unique attributes such as breathability, moisture-wicking, insulation, and natural comfort, which are essential in applications ranging from clothing and bedding to industrial uses. In a world where consumers appreciate quality and functionality, these natural materials offer a combination of versatility and performance. In addition, as the textile industry undergoes a transformation in response to sustainability challenges, fashion and interior design industries are increasingly adopting natural fiber felts in their creations. They are considered authentic, and their use is often accompanied by stories of responsible sourcing and environmentally friendly production, adding an appealing narrative to the products.

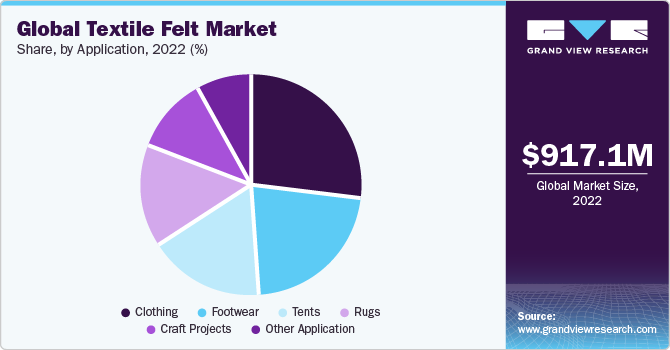

Application Insights

Based on the Application, the product market is segmented into footwear, clothing, tents, rugs, craft projects, and others. The clothing segment held the largest market share in 2022. Sustainability has become a pivotal concern in the fashion industry, and felt, especially when produced from natural fibers such as wool, aligns with eco-friendly principles. This has made felt an attractive choice for environmentally conscious consumers seeking clothing options that are biodegradable and manufactured with minimal ecological impact.

Furthermore, the insulating properties and natural comfort of felt make it a sought-after material for clothing. As consumers increasingly prioritize functionality and comfort, felt garments are gaining prominence, particularly in colder climates where the insulation properties of felt plays a crucial role. Additionally, the unique textural and aesthetic appeal of felt is another driving force behind the rising demand in the clothing sector. Fashion designers are incorporating felt into their creations to offer consumers visually distinctive and textured garments, setting them apart from more conventional fabric options.

Regional Insights

Asia Pacific dominated with the largest market share in 2022. Asia Pacific is home to some of the world's fastest-growing economies, and as a result, there is a significant expansion in various industries, such as automotive, construction, and fashion. These sectors increasingly rely on textile felts for applications like soundproofing, insulation, and innovative clothing designs. Additionally, Asia Pacific countries have witnessed a growing awareness of sustainability and eco-friendliness. Natural fiber-based products, often sourced from the region's abundant raw materials, are gaining favor among environmentally conscious consumers and industries. Wool and bamboo, for instance, are materials readily available in the region and are being used to create sustainable and biodegradable textile felts. According to the Invest India, textile & apparel industry in India stand as the 4th largest exporter in 2021 with textile industry anticipated to reach at USD 250 billion by 2030. Thus, the advancing textile industry in the region is anticipated to drive the product demand over the forecast period.

Competitive Insights

Some of the players operating in the market are Aetna Felt, Pugalia Woolen Mills Private Limited, Swicofil AG, FilzFelt, BWF Group, and Boer Group Recycling Solutions among others. The product market is competitive and evolving, influenced by various factors including technological advancements, sustainability concerns, and changing consumer preferences. Moreover, manufacturers are continually exploring innovative production techniques to improve the quality and performance of the product. Advanced manufacturing processes, such as needle punching and wet felting, are being adopted to enhance the strength, texture, and durability of felt materials.

In June 2023, Boer Group, a global organization specializing in textile recycling, announced its collaboration with trinamiX GmbH. This partnership aims to enhance Boer Group's textile sorting capabilities, ultimately improving the efficiency of its textile felt business operations.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."