Self-sanitizing Plastics Market Size, Share & Trends Analysis Report By Product (Antimicrobial Additives, Coatings, Inherently Antimicrobial Plastics), By Application (Automotive, Healthcare, Packaging), By Region, And Segment Forecasts, 2025 - 2030

- Report ID: GVR-4-68040-541-5

- Number of Report Pages: 130

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Bulk Chemicals

Self-sanitizing Plastics Market Size & Trends

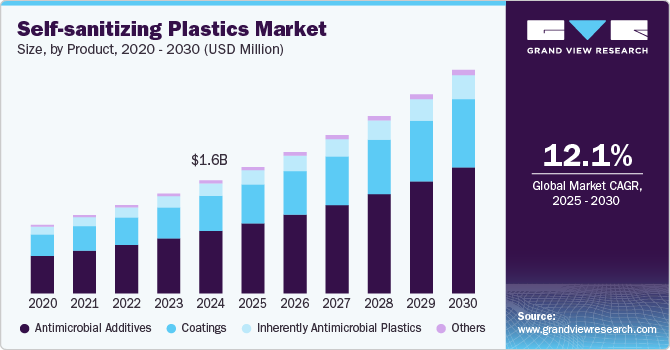

The global self-sanitizing plastics market size was estimated at USD 1.58 billion in 2024 and is projected to grow at a CAGR of 12.1% from 2025 to 2030. The increasing awareness of hygiene and infection prevention, particularly in the wake of the COVID-19 pandemic, has been a significant driver for market growth. Consumers and industries alike are prioritizing solutions that reduce the risk of microbial contamination. In the healthcare sector, self-sanitizing plastics are being widely adopted for medical devices, hospital equipment, and high-touch surfaces to minimize the spread of infections.

The healthcare and packaging industries are among the largest contributors to the growth of the self-sanitizing plastics industry. In healthcare, the need for sterile environments and infection-resistant materials has led to the widespread use of antimicrobial plastics in medical devices, surgical instruments, and hospital infrastructure.

In the packaging sector, self-sanitizing plastics are increasingly being used for food, beverage, and pharmaceutical packaging to extend shelf life and prevent contamination. The growing demand for safe and hygienic packaging solutions, coupled with stringent regulatory standards, is driving innovation and adoption in this segment.

Technological advancements in antimicrobial additives, coatings, and inherently antimicrobial plastics are fueling market growth. Researchers and manufacturers are developing innovative materials that offer long-lasting antimicrobial properties without compromising the durability or functionality of the plastic. For instance, the integration of silver ions, copper, and other antimicrobial agents into plastics has enhanced their effectiveness against a wide range of pathogens.

Advancements in nanotechnology and surface coatings are enabling the creation of self-sanitizing plastics that are more efficient and cost-effective. These innovations are expanding the application scope of self-sanitizing plastics, making them viable for use in automotive, consumer goods, and building & construction industries.

One of the key restraints in the self-sanitizing plastics industry is the high cost of production and raw materials, which can limit widespread adoption, particularly in price-sensitive regions and industries. The incorporation of advanced antimicrobial additives, coatings, or inherently antimicrobial materials often increases manufacturing costs, making these plastics more expensive than conventional alternatives.

The market faces challenges related to regulatory compliance and safety standards. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Chemicals Agency (ECHA), have stringent guidelines for the use of antimicrobial agents in plastics, especially in applications involving food contact, healthcare, and consumer goods.

These regulations ensure that self-sanitizing plastics are safe for human use and environmentally sustainable, but they can also slow down product approvals and increase development costs. Companies must navigate these regulatory hurdles while balancing innovation and compliance, which can act as a barrier to market growth.

Product Insights

The antimicrobial additives segment recorded the largest market revenue share of over 55.33% in 2024 and is projected to grow at the fastest CAGR of 12.5% during the forecast period. These additives, which include silver ions, copper, zinc, and organic compounds, are integrated into plastic materials during the manufacturing process to impart antimicrobial properties. They work by inhibiting the growth of bacteria, viruses, and fungi on the surface of the plastic, making them ideal for applications in healthcare, packaging, and consumer goods. The popularity of antimicrobial additives stems from their cost-effectiveness, ease of incorporation into existing plastic production processes, and versatility across a wide range of industries.

Coatings are another significant product in the market, offering a surface-level solution for antimicrobial protection. These coatings are applied to plastic surfaces to create a barrier that inhibits the growth of microbes, making them ideal for high-touch applications such as medical devices, consumer electronics, and automotive interiors.

The demand for antimicrobial coatings has surged in recent years, particularly in the healthcare sector, where they are used on hospital equipment, surgical tools, and other medical devices to reduce the risk of healthcare-associated infections (HAIs). Coatings are also gaining traction in the packaging industry, where they provide an additional layer of protection against contamination of food and pharmaceutical products.

Inherently, antimicrobial plastics are a specialized product in the market, offering built-in antimicrobial properties without the need for additives or coatings. These plastics are made from materials that naturally resist microbial growth, such as certain polymers or composites infused with antimicrobial agents during the polymerization process. This makes them highly effective for applications where long-term antimicrobial protection is critical, such as in healthcare, building materials, and consumer goods.

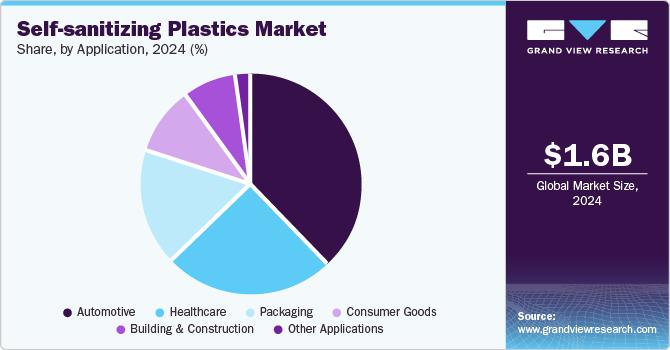

Application Insights

The automotive segment recorded the largest market share of 37.94% in 2024and is projected to grow at the fastest CAGR of 13.1% during the forecast period. The automotive industry is increasingly adopting self-sanitizing plastics to enhance passenger safety and hygiene, particularly in the wake of heightened awareness about cleanliness post-COVID-19. The product is used in high-touch interior components such as door handles, steering wheels, gear shifts, and dashboard surfaces to reduce the risk of microbial contamination. These materials help create a safer in-cabin environment, which is especially important for shared mobility solutions like ride-hailing services and public transportation.

The healthcare sector is one of the critical application areas for self-sanitizing plastics, driven by the urgent need to prevent infections and ensure patient safety. These plastics are widely used in medical devices, hospital equipment, surgical instruments, and high-touch surfaces such as bed rails, IV poles, and door handles. The antimicrobial properties of these materials help reduce the risk of healthcare-associated infections (HAIs), which are a significant concern in medical facilities. The COVID-19 pandemic further accelerated the adoption of self-sanitizing plastics in healthcare as hospitals and clinics sought to enhance infection control measures.

The packaging industry is a major application area for self-sanitizing plastics, particularly in food, beverage, and pharmaceutical packaging. These plastics help prevent microbial contamination, extend shelf life, and ensure product safety, making them essential for maintaining hygiene in the supply chain. For example, antimicrobial packaging is used for fresh produce, meat, and dairy products to reduce spoilage and minimize the risk of foodborne illnesses. In the pharmaceutical sector, self-sanitizing plastics are used for drug packaging to maintain sterility and protect sensitive medications.

Regional Insights

North America self-sanitizing plastics industry’s focus on sustainability and innovation is driving the development of eco-friendly, self-sanitizing plastics. However, high production costs and regulatory challenges can act as barriers to growth. Despite these challenges, North America is expected to maintain its leadership position, supported by continuous technological advancements and strong demand from key industries.

U.S. Self-Sanitizing Plastics Market Trends

The U.S. self-sanitizing plastics industry is largely driven by its advanced healthcare system, robust packaging industry, and high consumer awareness of hygiene. The country's healthcare sector is a major adopter of antimicrobial plastics, using them in medical devices, hospital equipment, and surgical instruments to reduce infection risks. The packaging industry is also a significant contributor, with increasing demand for antimicrobial solutions in food and pharmaceutical packaging. The U.S. market benefits from strong R&D capabilities and a focus on innovation, leading to the development of advanced self-sanitizing materials.

Asia Pacific Self-Sanitizing Plastics Market Trends

Asia Pacific self-sanitizing plastics industry dominated globally with the largest revenue share of over 52.63% in 2024 and is anticipated to grow at the fastest CAGR of 12.6% over the forecast period. Countries like China, India, and Japan are leaders in the adoption of these materials in healthcare, packaging, and consumer goods. The region's large population and expanding middle class are fueling demand for antimicrobial solutions, particularly in food packaging and medical devices. In addition, government initiatives to improve public health infrastructure and stringent regulations on food safety are further boosting market growth.

China self-sanitizing plastics industry accounted for a substantial share of regional demand in 2024. The country's healthcare sector is a major consumer of antimicrobial plastics, particularly for medical devices and hospital equipment, as the government prioritizes infection control. In addition, the packaging industry in China is rapidly adopting self-sanitizing plastics to meet the demand for safe and hygienic food and pharmaceutical packaging. The Chinese market also benefits from strong government support for innovation in materials science and sustainability.

Europe Self-Sanitizing Plastics Market Trends

Europe self-sanitizing plastics marketis significant for self-sanitizing plastics, driven by stringent hygiene regulations, advanced healthcare systems, and growing demand in the automotive and packaging industries. Countries such as Germany, the UK, and France are leading the adoption of these materials, particularly in healthcare and consumer goods. The region's focus on sustainability is also driving innovation in eco-friendly antimicrobial plastics. However, high production costs and regulatory complexities can limit market growth.

The self-sanitizing plastics industry in Germany is primarily driven by its strong healthcare sector, advanced manufacturing capabilities, and focus on innovation. The country's healthcare industry is a major consumer of antimicrobial plastics, using them in medical devices and hospital infrastructure to enhance infection control. Germany's automotive industry is also adopting self-sanitizing plastics for interior components to improve passenger safety. Additionally, the country's emphasis on sustainability is driving the development of eco-friendly antimicrobial materials. However, high costs and regulatory challenges can hinder growth.

Middle East & Africa Self-Sanitizing Plastics Market Trends

The Middle East & Africa self-sanitizing plastics industryis experiencing moderate growth, driven by increasing investments in healthcare infrastructure and construction projects. Countries in the Gulf Cooperation Council (GCC), such as the UAE and Saudi Arabia, are leading the adoption of these materials in healthcare and public infrastructure. The region's growing focus on hygiene and safety, particularly in the wake of the COVID-19 pandemic, is also boosting demand.

Key Self-sanitizing Plastics Company Insights

The self-sanitizing plastics industry is highly competitive, with key players focusing on innovation, strategic partnerships, and expanding their product portfolios to gain a competitive edge. The market is witnessing increased collaboration between manufacturers and end-users to develop customized solutions for specific applications. In addition, sustainability is becoming a key focus, with companies investing in eco-friendly and biodegradable self-sanitizing plastics to meet regulatory and consumer demands. As the market grows, competition is expected to intensify, driving further innovation and cost optimization.

- In February 2022, RMIT University in Australia introduced self-sanitizing bioplastics that repel liquids and dirt. The bioplastic is made from cheap and widely available raw materials-starch and cellulose-to keep production costs low and support rapid biodegradability. The product is ideal for fresh food and takeaway packaging applications.

Key Self-sanitizing Plastics Companies:

The following are the leading companies in the self-sanitizing plastics market. These companies collectively hold the largest market share and dictate industry trends.

- BASF SE

- DuPont

- Microban International

- Milliken & Company

- Parx Plastics

- BioCote Limited

- Lonza Group

- King Plastic Corporation

- Addmaster Limited

- Polychem Alloy Inc.

Self-sanitizing Plastics Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2025 |

USD 1.77 billion |

|

Revenue forecast in 2030 |

USD 3.13 billion |

|

Growth rate |

CAGR of 12.1% from 2025 to 2030 |

|

Historical data |

2018 - 2023 |

|

Forecast period |

2025 - 2030 |

|

Quantitative units |

Revenue in USD million, Volume in Kilotons, and CAGR from 2025 to 2030 |

|

Report Coverage |

Revenue forecast, volume forecast, competitive landscape, growth factors, and trends |

|

Segments Covered |

Product, application, region |

|

States scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

|

Key companies profiled |

BASF SE; DuPont; Microban International; Milliken & Company; Parx Plastics; BioCote Limited; Lonza Group; King Plastic Corporation; Addmaster Limited; Polychem Alloy Inc. |

|

Customization scope |

Free report customization (equivalent to 8 analyst’s working days) with purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Self-sanitizing Plastics Market Report Segmentation

This report forecasts revenue growth at a global level and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global self-sanitizing plastics market report based on product, application, and region:

-

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Antimicrobial Additives

-

Coatings

-

Inherently Antimicrobial Plastics

-

Other Products

-

-

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

Automotive

-

Healthcare

-

Packaging

-

Consumer Goods

-

Building & Construction

-

Other Applications

-

-

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

France

-

UK

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global self-sanitizing plastics market was estimated at around USD 1.58 billion in 2024 and is expected to reach around USD 1.77 billion in 2025.

b. The global self-sanitizing plastics market is expected to grow at a compound annual growth rate of 12.1% from 2025 to 2030, reaching around USD 3.13 billion by 2030.

b. The monomeric vinyl segment recorded the largest market revenue share, over 55.33%, in 2024. These additives work by inhibiting the growth of bacteria, viruses, and fungi on the surface of plastic, making them ideal for applications in healthcare, packaging, and consumer goods.

b. The key players in the self-sanitizing plastics market include BASF SE, DuPont, Microban International, Milliken & Company,Parx Plastics, BioCote Limited, Lonza Group, King Plastic Corporation, Addmaster Limited, Polychem Alloy Inc.

b. The self-sanitizing plastics market is driven by increasing awareness of hygiene and infection prevention, particularly in the wake of the COVID-19 pandemic. Furthermore, the packaging sector increasingly used self-sanitizing plastics for food, beverage, and pharmaceutical packaging to extend shelf life and prevent contamination

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."