- Home

- »

- Advanced Interior Materials

- »

-

Self Compacting Concrete Market Size & Share Report, 2030GVR Report cover

![Self Compacting Concrete Market Size, Share & Trends Report]()

Self Compacting Concrete Market Size, Share & Trends Analysis Report By Type (Powder, Viscosity, Combination), By End-use (Infrastructure, Oil & Gas, Building & Construction), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-322-3

- Number of Report Pages: 100

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

Self Compacting Concrete Market Trends

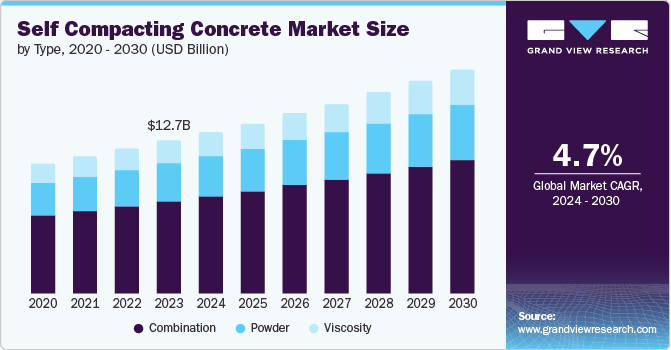

The global self compacting concrete market size was estimated at USD 12.71 billion in 2023 and is projected to grow at a CAGR of 4.7% from 2024 to 2030. This demand for self-compacting concrete (SCC) is growing due to its numerous benefits and applications in the global construction industry. One of the primary drivers is its exceptional workability and ease of use. SCC has the ability to flow under its own weight and completely fill formworks without the need for mechanical vibration. This property significantly reduces labor costs and construction time, while also minimizing the risk of accidents.

Additionally, SCC's capacity to reach and fill intricate spaces and densely reinforced areas makes it especially advantageous for complex structural projects and architectural designs that would be challenging to execute with conventional concrete. The market growth is attributed to the rising implementation of strict building codes and energy efficiency standards to reduce carbon footprints and promote sustainable development. Incentives such as tax benefits, subsidies, and grants around the world.

Another significant factor propelling the industry demand for SCC is its contribution to improved construction quality and durability. The uniformity and density achieved with SCC lead to higher-quality finished structures with enhanced strength and longevity. The elimination of mechanical vibration ensures a superior surface finish and reduces the potential for defects and weak points in the concrete, which can compromise structural integrity over time. This level of quality assurance is particularly critical in infrastructure projects such as bridges, tunnels, and high-rise buildings, where safety and durability are paramount.

Type Insights

The combination segment led the industry with the largest revenue share of 60.3% in 2023 and is forecasted to grow at a significant CAGR from 2024 to 2030. Combination-type SCC integrates the benefits of both viscosity modifying admixtures (VMA)-based and powder-type SCC. It incorporates viscosity-modifying agents to enhance the concrete's flow ability and stability, while also utilizing fine powders to improve the overall cohesion and resistance to segregation. This dual approach allows combination-type SCC to achieve superior performance characteristics, making it highly suitable for a wide range of applications. The versatility of combination-type SCC enables it to be effectively used in complex and densely reinforced structures, as well as in projects requiring high aesthetic quality and durability.

Powder type SCC is expected to grow at the highest CAGR of 5.1% from 2024 to 2030. Different types of cementitious materials, including Portland cement, fly ash, slag, and other supplementary cementitious materials, are utilized in SCC formulations. The choice of powder type directly impacts the mix's strength, durability, and environmental characteristics. The type and proportion of these cementitious materials significantly influence the compressive strength and overall performance of SCC. For instance, the addition of materials such as fly ash or slag can enhance long-term strength and reduce the heat of hydration. This results in more durable concrete with fewer thermal cracks, thereby extending the lifespan of the structure.

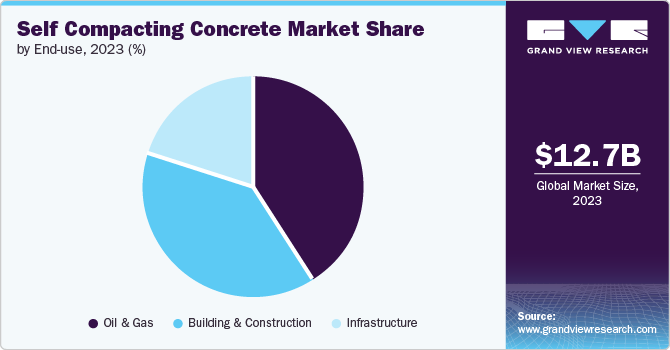

End-use Insights

The oil & gas segment dominated the self compacting concrete market in 2023 with the revenue share of 40.5%. This is expected to grow at a fastest CAGR of 4.9% from 2024 to 2030. This oil and gas industry often involves constructing facilities and infrastructure in complex and challenging environments, such as offshore platforms, refineries, and storage tanks. These structures require materials that can ensure high durability and reliability under harsh conditions, including exposure to chemicals, extreme temperatures, and high pressure. SCC’s ability to provide a dense, homogeneous mix with minimal voids makes it ideal for creating structures that can withstand such demanding environments.

This demand for self-compacting concrete (SCC) is high in building and construction applications due to its remarkable properties and advantages that align perfectly with the needs of modern construction projects. One of the foremost factors is SCC’s superior workability. SCC can flow under its own weight to completely fill formworks, even in highly congested areas with dense reinforcement, without the need for mechanical vibration. This property significantly reduces labor costs and construction time, making it highly desirable in the building and construction sector, where efficiency and cost-effectiveness are crucial.

Another critical factor driving the high demand for SCC in the building and construction industry is the enhanced quality and durability it offers. SCC ensures uniformity and density in the final structure, resulting in improved strength and longevity. The elimination of mechanical vibration minimizes the risk of voids and weak points, which are common in conventional concrete and can lead to structural failures. This aspect is particularly important in infrastructure projects such as bridges, roads, and tunnels where structural integrity and safety are paramount. The high-quality finish achieved with SCC also reduces the need for additional finishing work, further lowering overall project costs.

Regional Insights

The rate of adoption of newer technologies is higher in North America. SCC, with its superior workability and ease of placement, fits well into the region’s drive towards more efficient and innovative construction methods. This ability of SCC to flow under its own weight and fill intricate formworks without mechanical vibration reduces labor costs and speeds up construction timelines. This efficiency is particularly valuable in a market where labor shortages are a growing concern.

U.S. Self Compacting Concrete Market Trends

The construction industry in the U.S. is governed by stringent regulatory and industry standards that emphasize quality, safety, and sustainability. SCC meets these standards by providing a reliable and high-performance concrete solution that enhances the overall quality and safety of construction projects. The material’s consistent performance and compliance with industry regulations further drive its adoption across the country.

Europe Self Compacting Concrete Market Trends

Environmental sustainability is a significant concern in the Europe construction industry. SCC supports sustainable construction practices by incorporating supplementary cementitious materials such as fly ash, slag, and silica fume. These materials not only improve the properties of the concrete but also reduce the carbon footprint associated with cement production. Additionally, the use of SCC eliminates the need for mechanical vibration, thereby reducing noise pollution and energy consumption on construction sites. These environmental benefits align with the growing regulatory requirements and green building certifications in Europe.

Asia Pacific Self Compacting Concrete Market Trends

Asia Pacific region dominated the global self compacting concrete market with the largest revenue share of 45.8% in 2023 and is forecasted to grow at a fastest CAGR of 5.1% from 2024 to 2030. Asia Pacific is experiencing continuous urbanization and the development of infrastructure to support growing populations and economic activities. SCC is particularly well-suited for large-scale infrastructure projects due to its ability to enhance construction productivity and ensure high-quality outcomes. The material’s ability to flow and self-leveling properties make it ideal for constructing complex and large-scale projects efficiently, addressing the demands of urban expansion and modernization.

Key Self Compacting Concrete Company Insights

Some of the key players operating in the market include Cemex, and BASF SE

-

Cemex is engaged in manufacturing and distribution of self compacting concrete, ready-mix concrete, cement, and other aggregates in almost 50 countries across the world. Cemex along with its subsidies produces sells and distribute various construction materials, admixtures; concretes etc. apart from these, the company also provide complimentary products such as roof tiles, concrete blocks, asphalt products, concrete pipes and many other products for sewer and sanitary applications as well as in other precast areas including bridges, rail products, concrete floors, drainage basins etc.

-

BASF operates in major six segments including industrial solution, chemicals, agricultural solutions, materials, surface technologies and nutrition & care. This company has 361 production sites in over 90 countries worldwide, with footprints in various regions covering North America, South and Central America, Asia, Middle East and Africa.

Fletcher Building Group, and others are some of the emerging market participants in the market.

-

Fletcher Building Group, which is a multinational company that manufactures and distributes building products and services. Fletcher Building operates through six business divisions, namely building products, distribution, concrete, residential & development, and construction. Its product portfolio offers products including thermal insulation, acoustic insulation, fire rated insulation, building membranes, vapor permeable membranes, and tapes and accessories.

Key Self Compacting Concrete Companies:

The following are the leading companies in the self compacting concrete market. These companies collectively hold the largest market share and dictate industry trends.

- BASF SE

- CEMEX S.A.B. de C.V

- ACC Limited

- SIKA AG

- LafargeHolcim

- Kilsaran

- HEIDELBERGCEMENT AG

- Tarmac

- Unibeton Ready Mix

- Ultratech Concrete

- Fletcher Building

Recent Developments

-

In July 2022, Holcim signed an agreement with Ol-Trans, the leader in ready-mix concrete in the Gdansk-Sopot-Gdynia area, to acquire the latter's five concrete plants. The move is likely to strengthen Holcim's local ready-mix concrete network and firmly establish it as the leader in Northam Poland.

Self Compacting Concrete Market Report Scope

Report Attribute

Details

Market size value in 2024

USD 13.41 billion

Revenue forecast in 2030

USD 18.49 billion

Growth rate

CAGR of 4.7% from 2024 to 2030

Base year for estimation

2023

Historical data

2018 - 2022

Forecast period

2024 - 2030

Quantitative units

Revenue in USD million and CAGR from 2024 to 2030

Report coverage

Revenue forecast, company ranking, competitive landscape, growth factors, and trends

Segments covered

Type, end-use, region

Regional scope

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa

Country scope

U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; China; Japan; India; South Korea; Brazil; Saudi Arabia

Key companies profiled

BASF SE; CEMEX S.A.B. de C.V; ACC Limited; SIKA AG; LafargeHolcim; Kilsaran; HEIDELBERGCEMENT AG; Tarmac; Unibeton Ready Mix; Ultratech Concrete; Fletcher Building

Customization scope

Free report customization (equivalent up to 8 analysts’ working days) with purchase. Addition or alteration to country, regional & segment scope.

Pricing and purchase options

Avail customized purchase options to meet your exact research needs. Explore purchase options

Global Self Compacting Concrete Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global self compacting concrete market report based on type, end-use, and region:

-

Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Powder

-

Viscosity

-

Combination

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Oil & gas

-

Infrastructure

-

Building & Construction

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

-

Central & South America

-

Brazil

-

-

Middle East & Africa

-

Saudi Arabia

-

-

Frequently Asked Questions About This Report

b. The global self compacting concrete market size was estimated at USD 12.71 billion in 2023 and is expected to reach USD 13.41 billion in 2024.

b. The self compacting concrete market is expected to grow at a compound annual growth rate of 4.7% from 2024 to 2030 to reach USD 18.49 billion by 2030.

b. Among type, combination type segmented accounted for the largest market in 2023 with a revenue share of 60.4% as Combination-type SCC integrates the benefits of both VMA-based and powder-type SCC. Moreover, combination-type SCC offers significant advantages in terms of environmental sustainability.

b. Some of the key players operating in the self compacting concrete market include BASF SE, CEMEX S.A.B. de C.V, ACC Limited, SIKA AG, LafargeHolcim, Kilsaran, HEIDELBERGCEMENT AG, Tarmac, Unibeton Ready Mix, Ultratech Concrete, Fletcher Building

b. The key factor that is driving the self compacting concrete includes the rising construction activities in the developing countries around the world.

Share this report with your colleague or friend.

![gvr icn]()

NEED A CUSTOM REPORT?

We can customize every report - free of charge - including purchasing stand-alone sections or country-level reports, as well as offer affordable discounts for start-ups & universities. Contact us now

![Certified Icon]()

We are GDPR and CCPA compliant! Your transaction & personal information is safe and secure. For more details, please read our privacy policy.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."