Precision Machining Market Size, Share & Trends Analysis Report By Operation (Manual, CNC), By Type (Turning, Grinding), By End Use (Automotive, Industrial), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-459-9

- Number of Report Pages: 130

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2024 - 2030

- Industry: Technology

Precision Machining Market Size & Trends

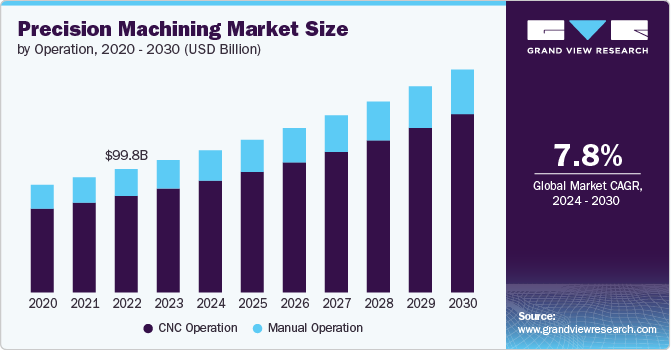

The global precision machining market size was estimated at USD 107.06 billion in 2023 and is expected to grow at a CAGR of 7.8% from 2024 to 2030. The growing adoption of automation and robotics in machining significantly contributes to the market's growth. Manufacturers increasingly incorporate computer numerical control machines and robotic systems into their operations to enhance efficiency, reduce errors, and increase production capacity. These technologies allow for more complex designs and faster turnaround times, making them indispensable in industries such as automotive, aerospace, and medical devices. Integrating AI and machine learning into machining processes is also beginning to revolutionize how machines are programmed and optimized, further boosting productivity.

The rising demand for high-performance materials is another major trend propelling the market. Industries such as aerospace, defense, and medical devices require more advanced materials, including composites, titanium, and other lightweight metals that can withstand extreme conditions. Precision machining is crucial for working with these materials, as it allows for creating parts with exact specifications and tight tolerances. This trend is particularly evident in aerospace, where lightweight components are essential for fuel efficiency and performance in aircraft and space vehicles.

The automotive industry's shift towards electric vehicles (EVs) is also driving demand for precision machining. EVs require different components than traditional internal combustion engine vehicles, and many of these parts, such as electric powertrains, batteries, and lightweight frames, necessitate precision machining. As the automotive sector transitions to more sustainable technologies, manufacturers are investing in precision machining to meet the stringent requirements for accuracy and durability in EV components. The growing focus on reducing vehicle weight to improve efficiency further highlights the importance of precision machining in the automotive industry.

Medical device manufacturing is another critical area where precision machining is gaining momentum. The need for highly accurate and customized components has skyrocketed as the healthcare industry moves toward more complex and minimally invasive surgical tools, implants, and diagnostic equipment. Precision machining enables the production of tiny, intricate parts with the tight tolerances required for medical devices, where precision is critical to ensure safety and performance. The increasing demand for personalized medical treatments, such as custom prosthetics and implants, is further fueling growth in this sector.

Global supply chain shifts are influencing the market. Companies increasingly seek to diversify their supply chains and reduce dependence on single-source regions. This trend has led to reshoring manufacturing activities, particularly in North America and Europe, where investments in precision machining technologies are rising. As a result, the market is seeing increased demand for localized production capabilities to enhance supply chain resilience and reduce lead times. This shift is driving growth in traditional markets and encouraging the adoption of advanced machining technologies in emerging economies.

Operation Insights

Based on operation, the CNC operation segment led the market and accounted for 78.5% of the global revenue in 2023. CNC operation dominates the market because it delivers high precision, efficiency, and scalability. Industries such as automotive, aerospace, and medical devices are increasingly adopting CNC machining to produce complex parts with tighter tolerances and faster production times. The automation involved in CNC operations reduces human error and allows for continuous, round-the-clock manufacturing, driving cost efficiency. Emerging technologies, including AI integration and real-time data analytics, further enhance CNC capabilities, making it the go-to choice for advanced manufacturing.

The manual operation segment is expected to grow significantly from 2024 to 2030. Despite the rise of automation, manual machining remains relevant, especially in custom, small-batch, or specialized work where flexibility is required. Skilled machinists can adjust parameters in real time, making manual operation valuable for intricate, low-volume projects that require a high level of craftsmanship. Sectors such as repair services and smaller manufacturing industries still rely on manual operations for tasks that don’t justify full CNC automation. As industries such as construction and industrial machinery expand, there remains a growing need for manual machining in areas that require a human touch for precise adjustments.

Type Insights

The milling machining segment accounted for the largest market revenue share in 2023. Milling machining is the dominant segment in the market due to its versatility and ability to handle a wide range of materials and complex geometries. It is widely used across industries such as automotive, aerospace, and industrial manufacturing to produce precise components with high accuracy. The flexibility of milling machines to perform multiple operations, such as drilling and cutting, in one setup makes them a crucial tool in modern manufacturing. Advances in multi-axis CNC milling have enhanced their efficiency, allowing for faster production times and reduced operational costs. With its proven reliability and broad applications, milling machining continues to be the backbone of precision machining processes worldwide.

The laser machining segment is expected to grow significantly from 2024 to 2030. Laser machining is an emerging segment with growing potential, particularly in industries such as electronics, medical devices, and aerospace, where high precision and minimal material waste are essential. This technology excels in cutting, engraving, and micro-machining, allowing manufacturers to create intricate designs on small-scale components with exceptional accuracy. The non-contact nature of laser machining also makes it ideal for working with delicate materials that are challenging for traditional methods. As demand for miniaturization and complex parts increases, especially in high-tech sectors, laser machining is poised to grow rapidly. Its ability to handle cutting-edge materials and reduce production times positions it as a key player in the future of precision manufacturing.

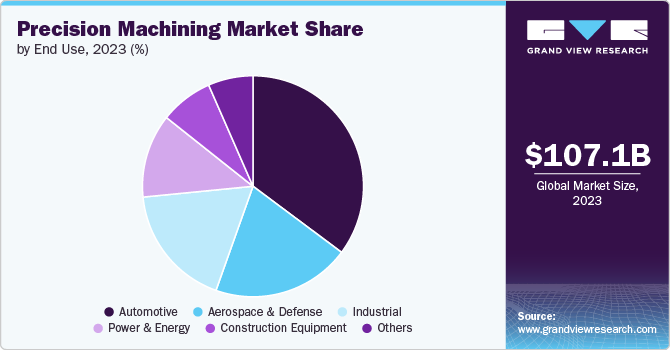

End Use Insights

The automotive segment accounted for the largest market revenue share in 2023. The need for high-precision components in engines, transmissions, and other critical systems drives the segment's growth. Precision machining plays a crucial role in producing the intricate parts required for traditional internal combustion engines and EVs. With the global shift towards EVs and more stringent emissions regulations, automotive manufacturers increasingly rely on precision machining to create lightweight, high-performance parts that improve efficiency. In addition, the demand for high-quality components in the automotive aftermarket continues to support growth in this segment.

The aerospace & defense segment is expected to grow significantly from 2024 to 2030. The aerospace & defense sector is experiencing emerging market growth due to the increasing demand for lightweight, durable, and complex components. Precision machining is essential for producing critical parts such as turbine blades, landing gear, and aircraft structural elements that must meet stringent safety and performance standards. As advancements in aerospace technology, including space exploration and next-generation aircraft, drive innovation, the need for precision-machined parts is becoming more pronounced. In defense, modernization efforts, and more advanced military equipment production also require precision machining for high-tolerance components.

Regional Insights

Asia Pacific precision machining market dominated the global market and accounted for 32.67% in 2023. The region’s booming manufacturing sectors, particularly in China, Japan, and South Korea, significantly contribute to the market's growth. The presence of strong automotive, electronics, and aerospace industries in this region fuels high demand for precision-machined components. Moreover, the rapid industrialization in emerging economies such as India and Southeast Asia is further contributing to the growth of this market. Asia Pacific benefits from a well-established supply chain, competitive labor costs, and the growing adoption of advanced machining technologies. As a result, the region is expected to continue leading the global market in production capacity and innovation.

North America Precision Machining Market Trends

The precision machining marketinNorth America is poised for significant growth from 2024 to 2030. North America is a prominent region in the market, largely due to its advanced aerospace, defense, and automotive industries. The region is home to major aerospace and automotive manufacturers that require high-precision components for complex applications. In addition, the increasing focus on advanced manufacturing technologies, such as CNC machining and additive manufacturing, is driving growth in this region. The region also benefits from a skilled workforce and significant investments in R&D, which help maintain its competitive edge. With the rise of electric vehicles and the ongoing demand for defense equipment, North America is expected to see continued demand for precision machining.

The U.S. precision machining market is anticipated to grow significantly from 2024 to 2030. The U.S. stands out as a major hub for precision machining, driven by its leadership in high-tech industries such as aerospace, defense, and medical devices. The country’s well-established manufacturing sector and focus on innovation make it a key market for advanced machining technologies, such as multi-axis CNC machines and laser machining. Furthermore, the U.S. defense sector’s need for precision components is a significant driver as the government continues to invest in military modernization.

Europe Precision Machining Market Trends

The precision machining market in Europe is poised for significant growth from 2024 to 2030. Countries such as Germany, France, and the U.K. are at the forefront, with well-established engineering industries that rely heavily on precision machining to produce high-quality components. The region also sees increasing adoption of advanced machining technologies to stay competitive in the global market. Europe’s commitment to sustainable practices and the production of lightweight components, particularly in the automotive and aerospace industries, is boosting the need for precision machining.

Key Precision Machining Company Insights

The market players are focusing on technological advancements and strategic partnerships to strengthen their market position. Companies are increasingly adopting automation, CNC technology, and advanced materials to meet growing industry demands for high-precision components in sectors such as aerospace, automotive, and medical devices. Many are also expanding their global footprint through mergers, acquisitions, and collaborations to access new markets and enhance their production capabilities.

Many companies in the market are actively implementing product launch strategies to expand their presence across different regions. For instance, in November 2023, Kennametal India’s WIDMA Machining Solutions launched the VT850, a 2-axis vertical turning lathe, specifically designed for precision machining of large components such as pumps, valves, and automobile parts. Built at their Bangalore facility, the VT850 offers high productivity and multiple machining operations without compromising quality. It features a double row cylindrical bearing for spindle stiffness and FEA-optimized structures for improved rigidity and vibration dampening. The lathe has a maximum turning diameter of 850 mm and includes options for high torque with a single-speed gearbox. Additionally, its 30/22 kW high-power work spindle and LM roller guideways are optimized for heavy and intermittent cutting.

Key Precision Machining Companies:

The following are the leading companies in the precision machining market. These companies collectively hold the largest market share and dictate industry trends.

- Ascentec Engineering

- Astro Machine Works

- Barnes Group Inc.

- DMG Mori Co., Ltd.

- ELCON PRECISION LLC

- GF Machining Solutions Management SA

- GrovTec Machining

- Hexcel Corporation

- M.A.R.'s Engineering Company Inc.

- Oberg Industries

Precision Machining Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 114.94 billion |

|

Revenue forecast in 2030 |

USD 180.25 billion |

|

Growth rate |

CAGR of 7.8% from 2024 to 2030 |

|

Actual data |

2018 - 2023 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company market share, competitive landscape, growth factors, and trends |

|

Segments covered |

Operation, type, end use, region |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; MEA |

|

Country scope |

U.S.; Canada; Mexico; Germany; UK; France; China; India; Japan; South Korea; Australia; Brazil; Kingdom of Saudi Arabia (KSA); UAE; South Africa |

|

Key companies profiled |

Ascentec Engineering; Astro Machine Works; Barnes Group Inc.; DMG Mori Co., Ltd.; ELCON PRECISION LLC; GF Machining Solutions Management SA; GrovTec Machining; Hexcel Corporation; M.A.R.'s Engineering Company Inc.; Oberg Industries |

|

Customization scope |

Free report customization (equivalent to up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Precision Machining Market Report Segmentation

The report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global precision machining market based on operation, type, end use, and region.

-

Operation Outlook (Revenue, USD Billion, 2018 - 2030)

-

Manual Operation

-

CNC Operation

-

-

Type Outlook (Revenue, USD Billion, 2018 - 2030)

-

Milling Machining

-

Laser Machining

-

Electric Discharge Machining

-

Turning

-

Grinding

-

Others

-

-

End Use Outlook (Revenue, USD Billion, 2018 - 2030)

-

Automotive

-

Aerospace & Defense

-

Construction Equipment

-

Power & Energy

-

Industrial

-

Others

-

-

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

-

Middle East & Africa (MEA)

-

UAE

-

Kingdom of Saudi Arabia (KSA)

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global precision machining market size was estimated at USD 107.06 billion in 2023 and is expected to reach USD 114.94 billion in 2024.

b. The global precision machining market is expected to grow at a compound annual growth rate of 7.8% from 2024 to 2030 to reach USD 180.25 billion by 2030.

b. Asia Pacific dominated the precision machining market with a share of 32.67% in 2023. The region’s booming manufacturing sectors, particularly in China, Japan, and South Korea, are a significant factor contributing to the growth of the market.

b. Some key players operating in the precision machining market include Ascentec Engineering, Astro Machine Works, Barnes Group Inc., DMG Mori Co., Ltd., ELCON PRECISION LLC, GF Machining Solutions Management SA, GrovTec Machining, Hexcel Corporation, M.A.R.'s Engineering Company Inc., and Oberg Industries.

b. Key factors that are driving the market growth include the growing adoption of automation and robotics in machining and the rising demand for high-performance materials.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."