Material Handling Equipment Market In Biomass Power Plant Size, Share & Trends Analysis Report By Product (Industrial Trucks, Continuous Handling Equipment), By Application, By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-385-8

- Number of Report Pages: 100

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

Market Size & Trends

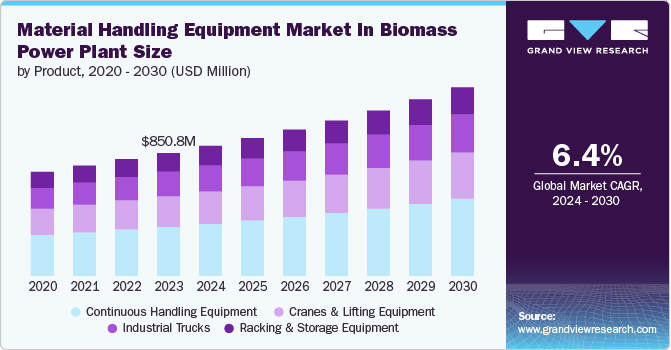

The global material handling equipment market in biomass power plant size was estimated at USD 850.8 million in 2023 and is projected to grow at a CAGR of 6.4% from 2024 to 2030. This growth is driven by the increasing adoption of biomass power as a sustainable energy source and the need for efficient material handling solutions in biomass power plants. Material handling equipment plays a crucial role in the transportation, storage, and processing of biomass feedstock, which includes pellets, wood chips, agricultural residues, and municipal solid waste (MSW).

The market is witnessing significant advancements in automation and control technologies, enhancing the efficiency and reliability of material handling operations. The integration of Internet of Things (IoT) and artificial intelligence (AI) in material handling equipment offers real-time monitoring and predictive maintenance capabilities, reducing downtime and operational costs. Furthermore, government incentives and policies promoting renewable energy projects are further propelling the demand for advanced material handling equipment in the biomass power sector. This technological evolution is expected to drive substantial growth and transformation within the market.

Drivers, Opportunities & Restraints

The growth of the material handling equipment market in biomass power plants is primarily driven by the rising demand for renewable energy sources and the increasing focus on reducing carbon emissions. Biomass power plants require efficient and reliable material handling solutions to manage various types of biomass feedstock, ensuring a continuous and smooth supply chain. Additionally, government incentives and policies promoting renewable energy projects are further propelling the demand for advanced material handling equipment in the biomass power sector.

The market also benefits from the expansion of biomass power projects in emerging economies, providing lucrative opportunities for market players to tap into new markets and expand their global footprint. Emerging markets are increasingly focusing on renewable energy to meet their growing energy demands and reduce dependence on fossil fuels. The growing environmental awareness and supportive government policies in these regions are likely to drive the demand for material handling equipment in biomass power plants.

However, the high initial investment and maintenance costs associated with material handling equipment pose a challenge to market growth. The complexity of handling diverse types of biomass feedstock and the need for specialized equipment and technology may also hinder the adoption of material handling solutions in some regions. Additionally, fluctuations in biomass feedstock supply and quality can affect the efficiency and performance of material handling systems, posing a challenge for market players.

Product Insights

“The demand for industrial trucks segment is expected to grow at a CAGR of 6.6% from 2024 to 2030 in terms of revenue”

Continuous handling equipment segment led the market, accounting for 39.8% of the global revenue share in 2023. Continuous handling equipment, such as conveyors and bucket elevators, are crucial for the continuous movement of biomass feedstock from storage areas to processing units. These systems ensure a steady and efficient flow of materials, reducing manual handling and operational delays.

Industrial trucks, including forklifts and loaders, are widely used for the transportation and loading of biomass materials within the power plant premises. The demand for industrial trucks is driven by their versatility and ability to handle various types of biomass feedstock. Racking and storage equipment play a vital role in the organized storage and retrieval of biomass feedstock. These systems help in optimizing storage space and ensuring quick and easy access to materials, enhancing overall operational efficiency.

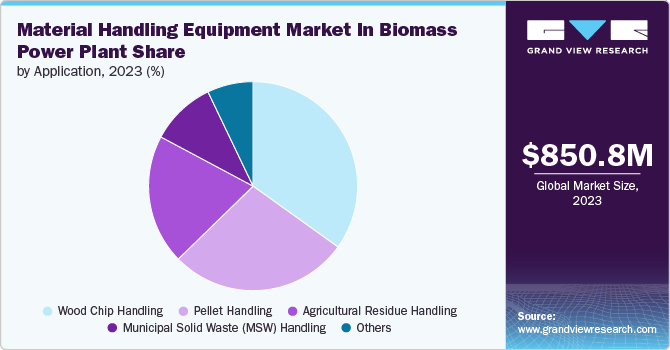

Application Insights

“The pellet handling application segment is expected to grow at a significant CAGR of 7.0% from 2024 to 2030 in terms of revenue”

The wood chip handling application segment held the largest revenue share in 2023, accounting for 34.9% of global market . Wood chip handling equipment is essential for the transportation and processing of wood chips, which are a primary feedstock in many biomass power plants. The growing use of wood chips as a renewable energy source contributes to the demand for advanced handling solutions.

The pellet handling segment is expected to witness significant growth from 2024 to 2030. The increasing use of biomass pellets as a fuel source in power plants drives the demand for specialized handling equipment designed to manage pellets efficiently. The agricultural residue handling segment is projected to grow steadily, driven by the utilization of crop residues and other agricultural by-products as biomass feedstock. Efficient handling equipment is required to manage the bulk and variability of agricultural residues.

Regional Insights

“Germany to witness market growth at 6.6% CAGR over the forecast period”

Europe material handling equipment in biomass power plants market is leading, supported by stringent environmental regulations and ambitious renewable energy goals. The region's focus on sustainability and circular economy principles promotes the adoption of advanced material handling solutions in biomass power projects. Countries like Germany, the UK, and France are at the forefront of implementing renewable energy initiatives, which drive the demand for material handling equipment.

The material handling equipment in biomass power plants market in Germany is a significant due to its strong commitment to renewable energy and stringent environmental regulations. The country has been a pioneer in adopting sustainable energy practices and has set ambitious targets for renewable energy generation. The demand for efficient and advanced material handling solutions in biomass power plants is driven by Germany's focus on reducing carbon emissions and promoting energy efficiency.

Asia Pacific Material Handling Equipment Market In Biomass Power Plant Trends

The Asia Pacific region is expected to witness the fastest growth from 2024 to 2030, driven by rapid industrialization, increasing energy demand, and government initiatives to promote renewable energy. Countries like China, India, and Japan are investing heavily in biomass power projects, creating significant opportunities for market players. The region's large population and growing energy needs make it a lucrative market for material handling equipment in biomass power plants.

North America Material Handling Equipment Market In Biomass Power Plant Trends

North America holds a substantial share of the material handling equipment market in biomass power plants, driven by the presence of established biomass power projects and supportive government policies. The region's focus on renewable energy and sustainable practices further boosts the demand for advanced material handling solutions. Additionally, the technological advancements and high adoption rate of automation in the industrial sector contribute to the market's growth in North America.

Key Material Handling Equipment Market In Biomass Power Plant Company Insights

Some key players operating in the market include BEUMER GROUP; Daifuku Co., Ltd.; ANDRITZ.,and KION GROUP AG among others

-

BEUMER GROUP is one of the leading players in the material handling equipment market, known for its innovative solutions in the biomass power sector. The company specializes in providing high-performance equipment such as conveyors, sorters, and palletizers that enhance efficiency and reliability in biomass power plants. BEUMER GROUP’s focus on integrating advanced technologies, such as automation and data analytics, into its material handling systems helps address the complexities of biomass feedstock handling and contributes to optimizing plant operations.

-

Daifuku Co., Ltd. Offer a comprehensive range of equipment for biomass power plants. The company’s product portfolio includes automated storage and retrieval systems, conveyors, and robotic solutions designed to handle various types of biomass feedstock efficiently. Daifuku's emphasis on automation and smart technology enables it to provide advanced material handling solutions that enhance operational efficiency and reduce downtime in biomass power facilities.

-

ANDRITZ is a prominent player in the material handling equipment market, renowned for its expertise in providing tailored solutions for the biomass power sector. The company offers a range of equipment, including conveyors, cranes, and storage systems, designed to handle biomass materials such as wood chips, pellets, and agricultural residues.

-

KION GROUP AG is a leading provider of industrial trucks and material handling solutions, including equipment used in biomass power plants. The company’s offerings encompass a wide range of products, from forklifts and reach trucks to automated guided vehicles (AGVs).

Key Material Handling Equipment Market In Biomass Power Plant Companies:

The following are the leading companies in the material handling equipment market in biomass power plants market. These companies collectively hold the largest market share and dictate industry trends.

- BEUMER GROUP

- Daifuku Co., Ltd.

- ANDRITZ

- KION GROUP AG

- Mecalux, S.A.

- Murata Manufacturing Co., Ltd.

- SSI SCHAEFER

- Swisslog Holding AG

- TOYOTA INDUSTRIES CORPORATION

- Vanderlande Industries B.V.

Recent Developments

-

In July 2023, Metso agreed to acquire Brouwer Engineering, an Australian firm specializing in automation, control systems, and electrical solutions for bulk material handling. This acquisition will integrate Brouwer Engineering's expertise in electrical and control systems with Metso's extensive experience in bulk material handling equipment and services. The combination aims to enhance Metso’s ability to offer a more comprehensive suite of solutions to its customers.

-

In May 2023, Toyota Material Handling (TMH) introduced three new electric forklift models, enhancing its already extensive range of material handling products and solutions. The latest additions include a Side-Entry End Rider, a Center Rider Stacker, and an Industrial Tow Tractor. These new models provide operators with a forward-facing position for improved visibility during load handling and feature a distinctive multifunction ergonomic control handle for enhanced ease of use.

Material Handling Equipment Market In Biomass Power Plant Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 900.7 million |

|

Revenue forecast in 2030 |

USD 1,306.5 million |

|

Growth rate |

CAGR of 6.4% from 2024 to 2030 |

|

Base year for estimation |

2023 |

|

Historical data |

2018 - 2022 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million/billion, and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

|

Segments covered |

Product, Application, region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Country Scope |

U.S., Canada, Mexico, Germany, France, Italy, UK, Spain, China, Japan, India, South Korea, Australia, Brazil, Argentina, South Africa, Saudi Arabia, UAE |

|

Key companies profiled |

BEUMER GROUP; Daifuku Co., Ltd.; ANDRITZ.; KION GROUP AG; Mecalux; S.A.; Murata Manufacturing Co., Ltd.; SSI SCHAEFER; Swisslog Holding AG; TOYOTA INDUSTRIES CORPORATION, Vanderlande Industries B.V. |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Material Handling Equipment Market In Biomass Power Plant Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global material handling equipment market in biomass power plants report based on the product, application, and region:

-

Product Outlook (Revenue, USD Million, 2018 - 2030)

-

Cranes & Lifting Equipment

-

Industrial Trucks

-

Continuous Handling Equipment

-

Racking & Storage Equipment

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Pellet Handling

-

Wood Chip Handling

-

Agricultural Residue Handling

-

Municipal Solid Waste (MSW) Handling

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

Japan

-

China

-

India

-

Australia

-

South Korea

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global material handling equipment market in biomass power plant size was estimated at USD 850.8 million in 2023 and is expected to reach USD 900.7 million in 2024.

b. The material handling equipment market in biomass power plant, in terms of revenue, is expected to grow at a compound annual growth rate of 6.4% from 2024 to 2030 to reach USD 1,306.5 million by 2030.

b. Europe dominated the material handling equipment market in biomass power plant with a revenue share of 35.2% in 2023. Countries like Germany, the UK, and France are at the forefront of implementing renewable energy initiatives, which drive the demand for material handling equipment in the region.

b. Some of the key players operating in the material handling equipment market in biomass power plant include BEUMER GROUP; Daifuku Co., Ltd.; ANDRITZ.; KION GROUP AG; Mecalux; S.A.; Murata Manufacturing Co., Ltd.; SSI SCHAEFER; Swisslog Holding AG; TOYOTA INDUSTRIES CORPORATION, Vanderlande Industries B.V.

b. The material handling equipment market in biomass power plant is driven by the rising demand for renewable energy sources and the increasing focus on reducing carbon emissions.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."