Logistics Automation Market Size, Share & Trends Analysis Report By Component, By Function, By Logistics Type, By Organization Size, By Software Application, By Vertical, By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-066-6

- Number of Report Pages: 250

- Format: PDF

- Historical Range: 2017 - 2023

- Forecast Period: 2024 - 2030

- Industry: Technology

Logistics Automation Market Size & Trends

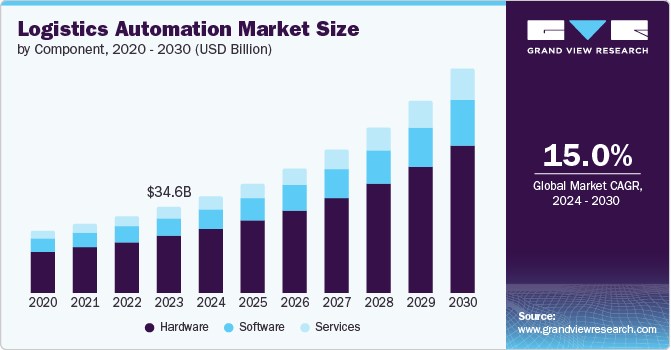

The global logistics automation market size was estimated at USD 34.56 billion in 2023 and is expected to grow at a CAGR of 15.0% from 2024 to 2030. Logistics automation includes hardware and software solutions to automate logistics processes such as transport, storage, retrieval, and data management processes. Automating these processes improves efficiency, minimizes errors, and reduces the turnaround time. Automation solutions aid in scaling up businesses as larger volumes can be easily managed with autonomous robots, conveyor systems, and automated storage systems.

The growing consumer inclination toward online shopping and rising demand for short delivery timelines is one of the major factors fueling the market's growth. High consumer demands have led to a surge in fulfillment centers for last-mile and quick deliveries. The fulfillment centers are incrementally adopting automation from mechanized support to operator-free equipment. As automated vehicle and robotics technologies mature with time, their applications in logistics and warehousing will broaden significantly and create growth opportunities for the target market during the forecast period.

The logistics automation sector faces several challenges, including intense market competition, a lack of industry standardization, and a shortage of skilled labor needed to operate advanced systems. The complexity of automation devices and software demands specific expertise, and the scarcity of trained personnel, particularly in developing countries like India and China, can hinder market growth. Additionally, the absence of standardization complicates the creation of uniform supply chain solutions, resulting in high costs for developing specialized systems.

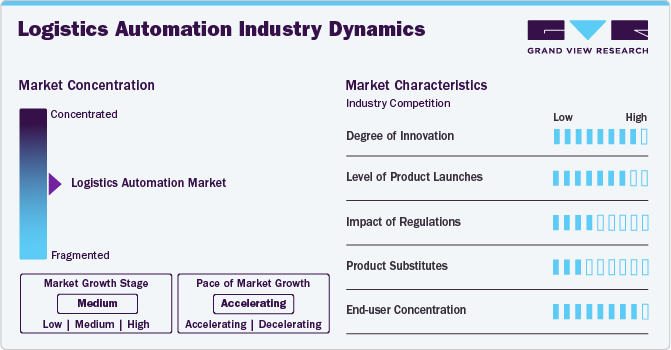

Market Concentration & Characteristics

The degree of innovation in the market is high. Cutting-edge technologies such as artificial intelligence, machine learning, and robotics are continually being developed and integrated into logistics operations. These innovations enhance efficiency, accuracy, and speed in supply chain management. Advanced automation systems, including autonomous vehicles and drones, are revolutionizing last-mile delivery. Smart warehouses equipped with IoT devices and sensors are optimizing inventory management and reducing operational costs. Developing countries, in particular, struggle with the adoption of these advanced systems due to a lack of expertise.

The high level of partnerships and collaboration in the market is primarily driven by the need to pool resources and expertise to tackle the complex challenges the industry faces. Companies often collaborate to combine their technological strengths and create more comprehensive and effective automation solutions. Partnerships allow firms to share the financial burden of research and development, making innovation more affordable and feasible.

Additionally, collaboration helps companies expand their market reach by leveraging each other's distribution networks and customer bases. The rapid pace of technological advancements necessitates continuous learning and adaptation, which is more efficiently achieved through collaborative efforts. Joint ventures and alliances also facilitate the standardization of technologies and practices, addressing the industry's need for uniformity. Furthermore, partnerships enable access to a broader talent pool, helping mitigate the shortage of skilled labor. Thus, by working together, companies can better navigate regulatory landscapes and enhance their competitive edge in a highly competitive market.

The impact of regulation on the market is moderate. Regulatory frameworks ensure safety and quality standards, which are crucial for the adoption of automated systems. However, these regulations can also impose additional compliance costs and administrative burdens on companies. While regulations aim to create a level playing field, they can sometimes slow down the pace of innovation and market entry for new players. In developing countries, regulatory environments may be less stringent, providing more flexibility but also leading to variability in standards. Overall, regulations play a balancing role, fostering both challenges and opportunities in the market.

The impact of product substitutes in the market is also moderate. Alternative solutions, such as manual labor or traditional mechanized systems, still play a significant role in many regions, particularly where labor costs are low. However, these substitutes often need more efficiency, accuracy, and scalability provided by advanced automation technologies. As automation systems become more cost-effective and accessible, their advantages over substitutes become more pronounced. Despite this, the initial investment and complexity of automation can make traditional methods more appealing in the short term. Thus, while substitutes exist, their impact is balanced by the growing benefits of automation.

End-use concentration is high in the market, with a significant portion of demand coming from large enterprises in sectors such as e-commerce, manufacturing, and retail. These industries have substantial logistical needs and are early adopters of automation technologies to enhance efficiency and reduce operational costs. The high volume of goods handled by these sectors necessitates advanced automation solutions to manage inventory, streamline supply chains, and ensure timely deliveries. Smaller businesses also contribute to market demand, but their adoption rates are slower due to budget constraints and scale of operations. The focus of automation providers on catering to the needs of large, high-volume clients further amplifies this concentration.

Additionally, large enterprises often require customized and integrated solutions, driving the demand for sophisticated automation systems. The reliance on these major sectors creates a concentrated market dynamic, where a few key industries dominate the landscape. This concentration can also lead to increased competition among automation providers to secure contracts with these large end-users.

Component Insights

Based on components, the hardware segment dominated the market with the largest revenue share of 66.6% in 2023. Based on the hardware, the market is further segmented into automated sorting systems, autonomous robots, conveyor systems, de-palletizing/palletizing systems, automated storage and retrieval systems, automatic identification and data collection. Due to the increasing demand for automated transportation, the autonomous robots category holds the largest market share among hardware solutions. Autonomous guided vehicles are expected to draw most of the spending in autonomous robots.

The software segment is expected to grow at a CAGR of 15.2% over the forecast period. This segment is further divided into warehouse management system and transportation management system. The warehouse management software automates and optimizes several warehouse processes, such as tracking, storing inventory, receiving, and workload planning, among others, and is expected to be the fastest-growing software solution during the forecast period. The market's continued expansion is primarily due to the increased demand for the deployment and integration of logistics automation.

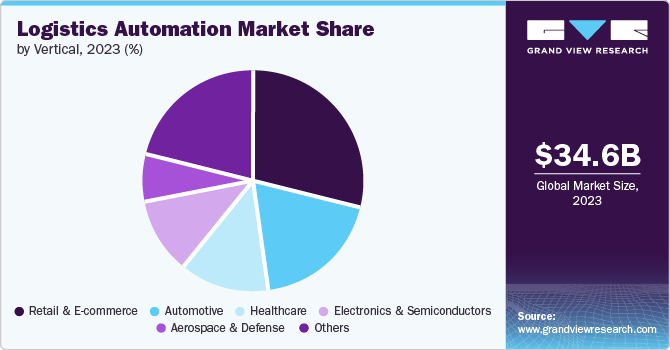

Vertical Insights

Based on vertical, the retail and e-commerce segment dominated the market with the largest revenue share in 2023. The sector uses logistics automation solutions in order to meet the increasing volumes of orders and shipments. Logistics automation solutions improve reliability and ensure timely delivery, which aligns with the retail and e-commerce industry's interest.

The healthcare segment is anticipated to register a significant growth over the forecast period. Logistics automation solutions for the healthcare industry provide safe and secure handling, storage, and retrieval of healthcare products such as pharmaceuticals and vaccines. The healthcare sector demands a high level of accuracy and accountability in order to ensure the safety of the products, and automation significantly helps to ensure it. Pharmaceutical products require precise inventory management to avoid shortages and track expiration duration.

Function Insights

Based on functions, the market is segmented into inventory & storage management and transportation management. The transportation management segment dominated the market with the largest revenue share in 2023. Autonomous robots, conveyor systems, and de-palletizing/palletizing systems are used for transportation management. Autonomous robots such as autonomous guided vehicles (AGV) and autonomous mobile robots (AMR) are motorized solutions that transport materials and products throughout the warehouse or manufacturing facility.

The inventory & storage management segment is expected to grow at the fastest CAGR of 16.2% over the forecast period. The inventory & storage management includes automated storage systems and automated retrieval systems. Autonomous storage systems enable the warehouses with the automated storage of crates or pallets on racks or shelves, while automated retrieval systems handle the product dispatch from the warehouse. Automating the inventory and storage process simplifies and accelerates tracking and tracing products in large warehouses.

Logistics Type Insights

Based on logistics type, sales logistics dominated the market with the largest revenue share in 2023. Sales logistics is the most critical aspect of the supply chain as it involves moving or delivering the goods to the end consumer. Sales logistics include order management, inventory management, shipping management, and vendor management. Automation solutions such as autonomous robots and automated storage and retrieval systems improve efficiency and reduce delivery turnaround time and hence are being increasingly adopted in sales logistics operations.

The production logistics segment is expected to grow at the fastest CAGR over the forecast period. Businesses heavily emphasize optimizing production processes, including time and cost optimization, to improve profitability. Logistics is one of the major expenditures of a business, and automation highly aids in minimizing or at least optimizing the expenditures to a large extent. Production logistics includes inventory management of raw materials, transportation within the manufacturing unit, and distribution.

Organization Size Insights

Based on organization size, large enterprises dominated the market with the largest revenue share in 2023. Large enterprises handle huge volumes of products through the entire supply chain processes, which include raw materials, inventory, and final products. Given the enhanced productivity, large enterprises are increasingly adopting automation solutions such as robots in manufacturing units and inventory warehouses for raw material handling.

The SME segment is expected to grow at the fastest CAGR over the forecast period. Small and medium enterprises focus heavily on cost efficiency and adopt automation solutions to minimize labor costs. Numerous startups are emerging in the e-commerce fulfillment service industry, with fulfillment centers increasingly adopting automated sorting systems for processes like kitting and bundling. Automation allows small and medium enterprises to compete more effectively with large enterprises.

Software Application Insights

Based on software applications, the market is segmented into inventory management, yard management, order management, labor management, vendor management, shipping management, customer support, and others. Among these, the order management segment dominated the market with the largest revenue share in 2023. Order management includes management of the entire lifecycle, including order entry, fulfillment of the order, delivery, and post-sale services. The adoption of order management is increasing as it offers visibility to both businesses and customers.

The inventory management segment is expected to grow at the fastest CAGR over the forecast period. Inventory management includes keeping track of the inventory levels, managing the inventory of each product, forecasting demand, and accounting for the entire inventory. Efficient inventory management is critical for a successful business as both excess and low inventory can be disastrous in the probability of a company. The demand forecasting of products depending on historical sales is highly beneficial in the maintenance of optimum inventory levels.

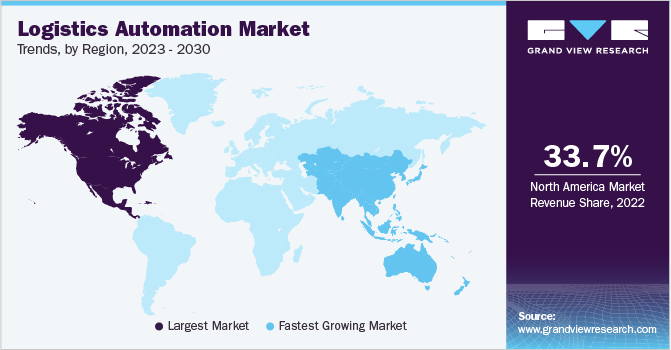

Regional Insights

North America led the logistics automation market in 2023, with a revenue share of 35.5%. The region's growth can be attributed to the presence of several logistics automation solution providers and several logistics companies, such as DHL, UPS, and FedEx Corporation, among others, in North America. In addition, the speedy implementation of modern technologies and the existence of modern infrastructure in the region a supportive factor in the growth of the target market. The U.S. is expected to retain its dominance over the forecast period owing to the rapid boom of the e-commerce sector in the country.

U.S. Logistics Automation Market Trends

The logistics automation market in the U.S. is driven by its well-established technological infrastructure and the presence of IT giants like Google, Microsoft, and Meta. The U.S. leads in technological infrastructure, ranking first in the frontier technologies readiness index in 2022, and is a major hub for robotics research and logistics automation, with significant contributions from companies like FORTNA Inc. and Honeywell International Inc. The rapid growth of automation is expected to drive the demand for logistics solutions. For instance, according to the International Federation of Robotics (IFR), in 2021, 34,987 robots were installed in the U.S. This represents the rapid growth of automation in the country. The trend is expected to propel the demand for logistics automation solutions such as Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs).

Asia Pacific Logistics Automation Market Trends

The logistics automation market in Asia-Pacific is expected to grow at the fastest CAGR of 15.5% over the forecast period. Asia Pacific is expected to experience rapid economic growth, especially in e-commerce. Moreover, Asia Pacific includes several countries which are hubs of logistical activity, such as Singapore, Indonesia, China, India, etc. Furthermore, the rising technological advancements and rising adoption of Industry 4.0 in countries such as China, India, Japan, and Southeast Asia countries are expected to boost the demand for logistics automation significantly over the forecast period.

China logistics automation market is experiencing rapid growth, fueled by the country's leadership in Research and Development (R&D) of advanced technologies. With a substantial number of patents in frontier technologies, such as the Internet of Things (IoT) and Artificial Intelligence (AI), China is poised for significant advancements in automation. Additionally, China's industrial sector, the largest globally, provides a solid foundation for the adoption of logistics automation systems, supported by substantial growth in equipment and high-tech manufacturing. The combination of these factors is driving robust growth in the logistics automation market in China.

Europe Logistics Automation Market Trends

The logistics automation market in Europe is growing due to the well-developed technological infrastructure, coupled with rising internet adoption and online shopping trends in the region. Countries such as Sweden, the Netherlands, Germany, and Finland are at the forefront of frontier technology readiness, further boosting the region's potential for automation. Leading companies in the region, including Cargotec, KNAPP AG, TGW Logistics Group, and Swisslog Holding AG, are contributing to market growth. Government investments in R&D, combined with increasing online shopping and proactive government initiatives, are key factors propelling the growth of logistics automation in Europe.

UK logistics automation market is growing due to the country's well-developed technological infrastructure and high internet adoption rates, which create a conducive environment for automation. Furthermore, the increasing demand for online shopping is driving the need for efficient logistics solutions, prompting companies to invest in automation. Moreover, government initiatives and support for R&D in automation technologies are further fueling the growth of the market in the UK.

Key Logistics Automation Company Insights

Some of the key companies operating in the logistics automation market include SAP., Jungheinrich AG, and Daifuku Co., Ltd., among others.

-

Jungheinrich AG is a supplier of warehousing technology and material handling equipment, offering extensive products and services. Its diverse product portfolio encompasses a wide range of equipment, including reach trucks, tow tractors, counterbalanced forklift trucks, shuttle and pallet carriers, order pickers, driverless transport systems, high rack stackers, rack servicing cranes, automatic high-rack silo conveyors, and materials handling systems. In addition, Jungheinrich AG provides various electric pedestrian trucks, explosion-proof forklifts, electric pedestrian stackers, batteries, and associated accessories. The company specializes in internal logistics services and delivers innovative solutions in warehousing technology.

-

Daifuku Co., Ltd. is an engineering, designing, manufacturing, installation, consultation, and after-sales service company for logistics systems and material handling equipment. The company caters to various industries, including automobile, transportation & warehousing, and commerce & retail. It has operations in 26 countries across Asia Pacific, Europe, and North America.

Kardex and One Network Enterprises are some of the emerging companies in the target market.

-

Kardex is a specialized supplier that provides material handling systems and automated storage solutions. Its extensive range of offerings is designed to meet the diverse needs of various industries. These offerings include buffering and sequencing solutions, automated storage and retrieval systems, document storage solutions, order fulfillment-controlled systems, and general contractor solutions. Kardex also offers specific modules, such as the horizontal carousel module, vertical buffer module, and storage solutions for totes, bins, trays, pallets, as well as heavy or oversized loads.

-

One Network Enterprises is a global technology company specializing in the development and implementation of advanced supply chain management solutions. With a focus on creating intelligent, end-to-end networks, the company offers a transformative platform that enables organizations to optimize their supply chain operations, collaborate effectively, and drive superior business outcomes. One Network Enterprises differentiates itself by offering a unique, cloud-based platform known as the Real Time Value Network (RTVN).

Key Logistics Automation Companies:

The following are the leading companies in the logistics automation market. These companies collectively hold the largest market share and dictate industry trends.

- Dematic (Kion Group AG)

- Daifuku Co., Ltd.

- Swisslog Holding AG (KUKA AG)

- Honeywell International Inc.

- Murata Machinery, Ltd.

- Jungheinrich AG

- KNAPP AG

- TGW Logistics Group

- Kardex

- Mecalux, S.A.

- BEUMER GROUP

- SSI SCHÄFER AG

- Vanderlande Industries B.V.

- WITRON Logistik

- Oracle

- One Network Enterprises

- SAP

Recent Developments

-

In February 2024, Dematic announced a partnership with Canadian logistics company Groupe Robert and opened Quebec's first fully automated cold storage facility for third-party logistics. The facility features a high-capacity Automated Storage and Retrieval System (AS/RS) with 130-foot-tall cranes for managing fresh and frozen products. It also prioritizes sustainability and advanced fire safety measures and aims to enhance supply chain efficiency and serve as a central hub for manufacturers distributing products across North America.

-

In May 2023, Swisslog Holding AG announced a partnership with Northern Tool + Equipment to implement a Swisslog Automation Solution within the latter’s facility in Fort Mill in the U.S. state of South Carolina. The collaboration was aimed at addressing the omnichannel distribution requirements of Northern Tool + Equipment. The solution designed by Swisslog Holding AG’s experts features the AutoStore system optimized using Swisslog Holding AG’s SynQ software. Anticipated to be fully operational by October 2023, the solution would significantly enhance the efficiency and effectiveness of Northern Tool + Equipment's operations.

-

In March 2023, Jungheinrich AG announced the acquisition of Storage Solutions, a material handling solution provider based in the U.S. Storage Solutions provides warehouse and distribution centers with solutions and services, such as lifecycle services, workflow optimization, and safety inspections. Jungheinrich AG was looking forward to leveraging the acquisition to expand its presence in the U.S.

Logistics Automation Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 38.89 billion |

|

Revenue forecast in 2030 |

USD 90.0 billion |

|

Growth Rate |

CAGR of 15.0% from 2024 to 2030 |

|

Actual Data |

2017 - 2023 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

|

Segments covered |

Component, function, logistics type, organization size, software application, vertical, region |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; MEA |

|

Country scope |

U.S.; Canada; Mexico; UK; Germany; France; China; Japan; India; South Korea; Australia; Brazil; KSA; UAE; and South Africa |

|

Key companies profiled |

Dematic (Kion Group AG); Daifuku Co., Ltd.; Honeywell International Inc.; Swisslog Holding AG (KUKA AG); Murata Machinery, Ltd.; Jungheinrich AG; TGW Logistics Group; KNAPP AG; Kardex; Mecalux, S.A.; BEUMER GROUP; SSI SCHÄFER AG; Vanderlande Industries B.V.; WITRON Logistik; Oracle; One Network Enterprises; SAP. |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Logistics Automation Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global logistics automation market report based on component, function, logistics type, organization size, software application, vertical, region:

-

Component Outlook (Revenue, USD Million, 2017 - 2030)

-

Hardware

-

Autonomous Robots (AGV, AMR)

-

Automated Storage and Retrieval Systems (AS/RS)

-

Automated Sorting Systems

-

De-palletizing/Palletizing Systems

-

Conveyor Systems

-

Automatic Identification and Data Collection (AIDC)

-

-

Software

-

Warehouse Management System

-

Transportation Management System

-

-

Services

-

Consulting

-

Deployment & Integration

-

Support & Maintenance

-

-

-

Function Outlook (Revenue, USD Million, 2017 - 2030)

-

Inventory & Storage Management

-

Transportation Management

-

-

Logistics Type Outlook (Revenue, USD Million, 2017 - 2030)

-

Sales Logistics

-

Production Logistics

-

Recovery Logistics

-

Procurement Logistics

-

-

Organization Size Outlook (Revenue, USD Million, 2017 - 2030)

-

Large Enterprises

-

Small & Medium Enterprises

-

-

Software Application Outlook (Revenue, USD Million, 2017 - 2030)

-

Inventory Management

-

Order Management

-

Yard Management

-

Shipping Management

-

Labor Management

-

Vendor Management

-

Customer Support

-

Others

-

-

Vertical Outlook (Revenue, USD Million, 2017 - 2030)

-

Retail & E-commerce

-

Healthcare

-

Automotive

-

Aerospace & Defense

-

Electronics & Semiconductors

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2017 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

-

Middle East and Africa (MEA)

-

KSA

-

UAE

-

South Africa

-

-

Frequently Asked Questions About This Report

b. The global logistics automation market size was estimated at USD 34.56 billion in 2023 and is expected to reach USD 38.89 billion in 2024.

b. The global logistics automation market is expected to grow at a compound annual growth rate of 15.0% from 2024 to 2030 to reach USD 90.00 billion by 2030.

b. Inventory and storage management function is forecasted to register the highest CAGR of 16.2% from 2024 to 2030. The inventory & storage management ensures the stocks are maintained at optimum levels, and the demand for each product determines the stock levels.

b. Major players operating in the logistics automation market include Dematic Corp. (Kion Group AG), Daifuku Co. Limited, Swisslog Holding AG (KUKA AG), Honeywell International Inc., Jungheinrich AG, Murata Machinery Ltd, and Knapp AG.

b. The major factors attributing to the growth of the logistics automation market are the rapid growth of the e-commerce sector, which has led to a surge of e-commerce fulfillment centers; increasing adoption of automation equipment such as robots, conveyor systems, and storage systems; and supportive government initiatives to build a robust logistics infrastructure.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."