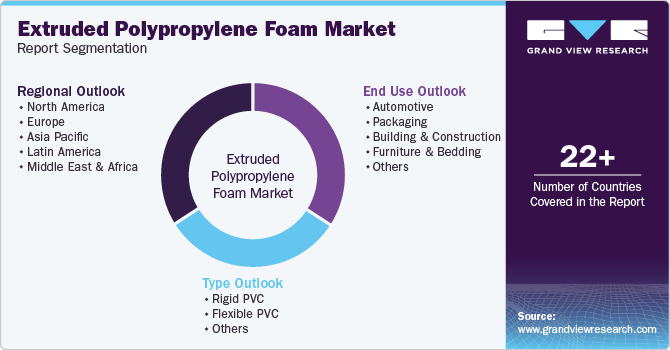

Extruded Polypropylene Foam Market Size, Share & Trends Analysis Report By Type (Rigid PVC, Flexible PVC), By End-use (Automotive, Packaging, Building & Construction, Furniture & Bedding), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-1-68038-511-3

- Number of Report Pages: 100

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Bulk Chemicals

Extruded Polypropylene Foam Market Trends

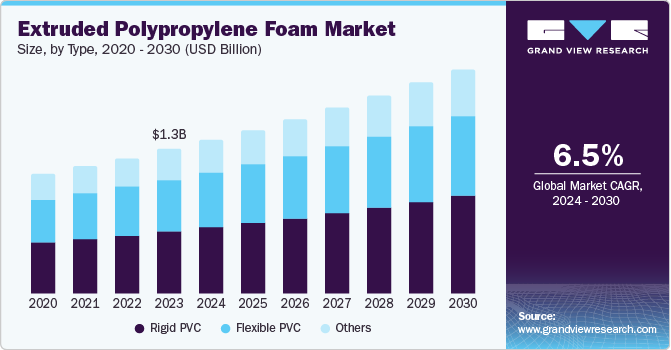

The global extruded polypropylene foam market size was valued at USD 1.30 billion in 2023 and is projected to grow at a CAGR of 6.5% from 2024 to 2030. The increasing consumer demand for eco-friendly packaging materials for FMCG products has primarily driven the market growth. These foams offer superior shock absorbency and high melt strength, making them ideal for protecting products during transportation.

In addition, the demand for XPP foams is projected to increase rapidly due to the automotive industry’s adoption of new technologies focused on reducing vehicle weight. Implementing new global emission regulations is expected to emphasize the importance of lightweight materials in key automotive components such as seats for their cushioning properties. Their application extends to engine sheds, door liners, and roof trunk liners. Moreover, the growing awareness about lightweight vehicles and improved fuel efficiency is anticipated to drive the consumption of these products further.

Furthermore, the booming growth of the construction sector has led to an increased demand for XPP foam for energy efficiency. These foams are used as insulating materials in homes and refrigerators. They align with building codes by reducing heating and cooling costs and promoting energy-efficient structures. These foams are stiff, noise-resistant, lightweight, and can provide high impact resistance. They offer moisture protection in buildings, preventing harmful molds and mildew.

Type Insights

Rigid PVC foams dominated the market with a share of 43.2% in 2023, owing to the growth of the construction industry. Rigid PVC is durable, corrosion-resistant, low maintenance, and has a lower environmental impact than other plastics. This has led to widespread adoption in the construction industry for insulation, piping, and other structural components. These XPP foams are used to build insulating materials, helping improve energy efficiency by reducing heating and cooling costs. The increasing adoption of energy-efficient building codes and the rising focus on sustainable construction practices have boosted the demand for these foams in this sector. In addition, the versatility of these foams in providing moisture resistance and preventing mold growth in buildings has made them a valuable material in the construction industry.

Flexible PVC foams will emerge as the fastest-growing segment over the forecast period. One of the primary drivers is the increasing demand for lightweight and energy-efficient materials, particularly required in the automotive and aerospace industries. Its flexibility allows for easy molding and shaping, which is essential for creating complex components in these sectors. Furthermore, this shift is largely influenced by stringent global emission regulations that emphasize using lightweight materials to enhance fuel efficiency and reduce carbon emissions. As a result, XPP foams, known for their excellent strength-to-weight ratio, have become a preferred choice for automotive manufacturers. These foams are used in various automotive components, including door panels, roof liners, and seat cushions, providing structural integrity and weight reduction.

Furthermore, the rising awareness and demand for eco-friendly packaging solutions have propelled the market growth. These XPP foams have been increasingly utilized in the packaging industry due to their superior shock absorbency, insulation properties, recyclability, and lower environmental impact than other foams, such as polyurethane (PU) and polyethylene (PE). They help protect products during transportation and storage, reducing damage and waste.

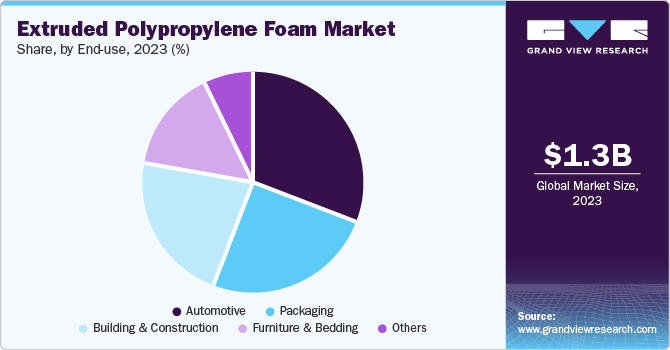

End-use Insights

The automotive segment dominated the market in 2023. The key market drivers of XPP foams in this sector were centered on the material’s lightweight, energy-absorbing, and environment-friendly properties. XPP foam is significantly lighter than traditional materials, including PU and PP, which helps reduce the overall weight of vehicles. This weight reduction translates to better fuel economy and lower carbon emissions, aligning with global regulatory standards and consumer preferences for greener cars. Its excellent energy-absorbing properties make it ideal for use in automotive components such as bumpers, door panels, and interior padding.

The packaging segment is projected to grow at a CAGR of 6.7% during the forecast period, owing to the increased adoption of XPP foams for sustainable packaging solutions. Their superior shock absorbency ensures product protection during transportation and storage, making them ideal for packaging applications. XPP foam is widely used for packaging fragile electronic products and appliances as it protects against impact during transportation. Its high melting point allows food containers to withstand microwave heating, making it suitable for food packaging. Furthermore, the easy availability and affordability of XPP foam have led to increased usage of the foam in the packaging industry.

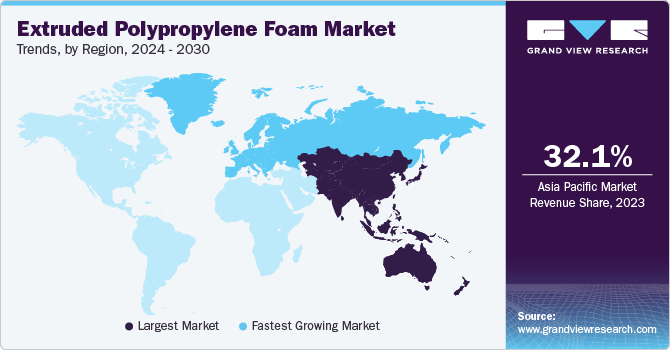

Regional Insights

The extruded polypropylene foam market in North America is expected to grow at the significant rate over the forecast period. The significant expansion in the automotive and construction sectors drives this growth. In addition, there is rising demand in the automotive and packaging industries. The shift towards electric and fuel-efficient vehicles drives the need for lightweight, high-performance materials, making XPP foam an attractive option. Furthermore, the packaging industry increasingly utilizes XPP foam for its protective qualities and recyclability, aligning with consumer preferences for sustainable solutions. These factors collectively support robust market growth in North America.

U.S. Extruded Polypropylene Foam Market Trends

The growth of the U.S. extruded polypropylene foam market was augmented by the rising demand for private and commercial vehicles and growth in the construction industry. Construction companies have extensively used XPP foam to improve the insulation of the buildings, reducing the cost of cooling and heating. In addition, automotive companies manufacturing private and commercial vehicles, including trucks and buses, have contributed to the market growth.

Asia Pacific Extruded Polypropylene Foam Market Trends

The Asia Pacific extruded polypropylene foam market dominated the global market with the largest revenue share of 32.1% in 2023. Rising urbanization in countries such as China, India, and Japan has led to an increased demand for products that cater to the needs of the growing urban population. These foams align with the increased demand for eco-friendly materials and superior absorbency for product protection. Furthermore, the booming automobile industry and rising disposable incomes will positively impact market growth.

The extruded polypropylene (XPP) foam market in China is expected to witness significant growth. This growth is driven by the country's constantly increasing construction and manufacturing activity. XPP foam is widely used in the automotive, packaging, building, and construction industries due to its superior characteristics, such as high-temperature resistance, chemical resistance, high strength-to-weight ratio, and recyclability. The rising demand for lightweight vehicle components and insulation materials in the construction sector is fueling the market growth in China.

Europe Extruded Polypropylene Foam Market Trends

The Europe extruded polypropylene foam market held a significant share of the global revenue in 2023. The increasing demand from the automotive and construction industries primarily drives this growth. The automotive sector focuses on lightweight materials to enhance fuel efficiency, while the construction industry seeks superior insulation solutions. In addition, stringent environmental regulations push manufacturers towards sustainable materials, further boosting the adoption of XPP foam due to its recyclability and eco-friendly properties. This trend is expected to contribute significantly to market expansion in the region.

Key Extruded Polypropylene Foam Company Insights

The global extruded polypropylene foam market is highly competitive, featuring numerous multinational corporations and small manufacturers with high production volumes. Some major extruded polypropylene foam market companies are DS Smith, LyondellBasell Industries Holdings B.V., Borealis AG., and others. These companies are extensively integrated, managing everything from the production of the foam to the sales and distribution of their products across various locations. They have increasingly focused on product improvement and mitigation of rising demand for EPP foam with the help of technological advancements, mergers and acquisitions, collaborations, and more.

-

LyondellBasell Industries Holdings B.V. is a global leader in the production of chemicals, polymers, and advanced polyolefin products. The company operates across Europe, North America, and the Asia-Pacific region and is renowned for its innovative material solutions and recycling technologies, which contribute to a more sustainable future.

- DS Smith is an international packaging company specializing in sustainable, fiber-based packaging solutions, integrated recycling services, and paper products. The company operates in over 37 countries and focuses on creating 100% recyclable packaging.

Key Extruded Polypropylene Foam Companies:

The following are the leading companies in the extruded polypropylene foam market. These companies collectively hold the largest market share and dictate industry trends.

- DS Smith

- LyondellBasell Industries Holdings B.V.

- Borealis AG

- Mitsubishi Chemical Group Corporation.

- Formosa Plastics Corporation, U.S.A.

- BASF SE

- Braskem

- Toray Industries Inc

- KURARAY CO., LTD.

Recent Developments

-

In June 2024, LyondellBasell Industries Holdings B.V. announced the start of operations at its Dalian facility under the Advanced Polymer Solutions (APS) business. This new production line manufactures polypropylene compounds for the automotive sector. The expansion enhances the company’s ability to meet the growing market demand.

Extruded Polypropylene Foam Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 1.39 billion |

|

Revenue forecast in 2030 |

USD 2.02 billion |

|

Growth rate |

CAGR of 6.5% from 2024 to 2030 |

|

Base year for estimation |

2023 |

|

Historical data |

2018 - 2022 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million, volume in kilotons and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

|

Segments covered |

Type, end-use, region |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; MEA |

|

Country scope |

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; Netherlands; Denmark; Sweden; Norway; China; India; Japan; South Korea; Thailand; Indonesia; Brazil; Argentina; South Africa; Saudi Arabia; UAE. |

|

Key companies profiled |

LyondellBasell Industries Holdings B.V.; Borealis AG.; Mitsubishi Chemical Group Corporation.; Formosa Plastics Corporation; U.S.A.; BASF SE; Braskem; Toray Industries Inc; KURARAY CO.; LTD. |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Extruded Polypropylene Foam Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global extruded polypropylene foam market report based on type, end-use and region.

-

Type Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

Rigid PVC

-

Flexible PVC

-

Others

-

-

End Use Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

Automotive

-

Packaging

-

Building & Construction

-

Furniture & Bedding

-

Others

-

-

Regional Outlook (Revenue, USD Million, Volume in Kilotons, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

Spain

-

Netherlands

-

Denmark

-

Sweden

-

Norway

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Thailand

-

Indonesia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East and Africa (MEA)

-

Saudi Arabia

-

South Africa

-

UAE

-

-

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."