Direct To Shape Printer Market Size, Share & Trends Analysis Report By Technology (Inkjet, Laser), By Type (Single Pass, Multi Pass), By Ink Type (UV-based, Solvent-based, Aqueous-based), By End-use, By Region, And Segment Forecasts, 2025 - 2030

- Report ID: GVR-4-68040-524-7

- Number of Report Pages: 100

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

Direct To Shape Printer Market Size & Trends

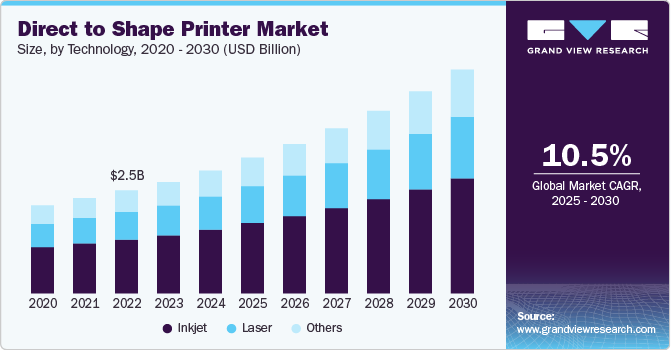

The global direct to shape printer market size was valued at USD 2.92 billion in 2024 and is projected to grow at a CAGR of 10.5% from 2025 to 2030. A key driver fostering market growth is the increasing demand for customized products, which direct to shape printers can efficiently produce. Additionally, advancements in 3D printing technology have led to improved print quality and speed, making the process more appealing to various industries.

Cost-effectiveness and the ability to print on irregular surfaces have expanded the market’s Ink Types across sectors like automotive, packaging, and consumer goods. Furthermore, the growing trend of personalized and on-demand manufacturing is pushing businesses to adopt direct to shape, also referred to as direct to object printing solutions.

Market Concentration & Characteristics

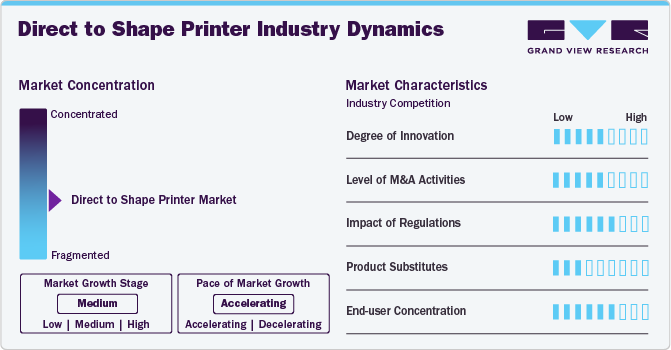

The global direct to shape printer industry is moderately fragmented, with a mix of large multinational corporations and smaller regional players competing for market share. Leading manufacturers focus on developing high-quality, versatile printers that can cater to a wide array of industries, including automotive, consumer goods, packaging, and healthcare. Innovation in this market is driven by the increasing demand for personalized products, reduced production costs, and the need for efficient, waste-reducing manufacturing processes. As businesses strive for higher levels of customization, direct to shape printers offer a solution that aligns with these growing demands.

Market dynamics are also shaped by the rise of sustainability concerns and eco-friendly manufacturing practices. As consumers and businesses increasingly prioritize environmentally responsible products, direct to shape printing technologies, which minimize waste and energy consumption, have become a significant point of focus for manufacturers. Regulations in various regions, especially around sustainability and waste reduction, push the industry toward the development of more energy-efficient and eco-friendly printing technologies. Companies that innovate with green solutions-such as printers using recyclable or biodegradable materials-are well-positioned to capture a share of the growing market driven by eco-conscious consumers and businesses.

Despite the market’s growth, the direct to shape printer market faces competition from traditional manufacturing methods as well as other advanced printing technologies like 3D printing. To remain competitive, manufacturers must continually innovate and integrate new technologies, such as AI and IoT, to offer smarter, more efficient solutions. As industries seek more sustainable and customizable production options, the direct to shape printer market must adapt to changing consumer preferences, technological advancements, and regulatory pressures to maintain its momentum. Emphasizing flexibility, eco-friendliness, and cost-efficiency will be key to sustaining market leadership in this dynamic, evolving industry.

Drivers, Opportunities & Restraints

The most significant driving factors for the industry include the increasing demand for customization and personalization across various industries. As consumers increasingly seek unique, tailored products, businesses are turning to direct to shape printing for cost-effective, efficient solutions to meet this need.

The restraints affecting the industry include high initial setup costs, which can deter small and medium-sized businesses from adopting the technology. There are also limitations in material compatibility, as not all materials work well with direct to shape printers. Furthermore, the technology still faces challenges related to print durability and surface quality, which can affect product reliability and consumer satisfaction.

Opportunities for growth in the industry lie in the increasing adoption of Industry 4.0 principles, as businesses seek to optimize production efficiency and customize offerings. Furthermore, expansion into emerging markets also presents opportunities, as local manufacturers adopt advanced technologies to enhance their product offerings and meet demand for unique, custom items.

Technology Insights

The inkjet segment dominated the market in 2024, accounting for 52% of the revenue share due to its ability to offer high-resolution, vibrant, and detailed prints across a wide range of substrates. This flexibility makes it ideal for industries like packaging, cosmetics, and consumer goods, where customization and quality are key differentiators. As demand for personalized and on-demand printing increases, especially in sectors such as food and beverage, inkjet printing technology is gaining traction for its cost-effective, high-quality output.

Laser technology in direct to shape printers is becoming increasingly popular due to its precision, speed, and efficiency in printing high-quality, durable markings on various surfaces. Its growing adoption in industries like automotive, electronics, and packaging is driven by the need for high-definition prints that can withstand harsh conditions such as abrasion and temperature variations. Additionally, laser printing provides a cleaner, more sustainable alternative to traditional ink-based printing methods, contributing to its growing preference in industrial applications.

End-use Insights

The food & beverage segment dominated the market in 2024, accounting for a 23.8% revenue share driven by the increasing need for packaging customization and high-quality branding. With an increasing emphasis on product differentiation and sustainability, manufacturers are turning to direct to shape printing to achieve unique packaging designs while maintaining the high print quality that meets food safety standards. Additionally, the need for efficient, on-demand printing solutions to accommodate shorter production runs and varying product batches is pushing growth in this sector.

The toys and sporting goods industry is witnessing growing adoption of direct to shape printers driven by the need for customized branding and intricate designs on products. As consumer preferences shift toward personalized products, manufacturers are seeking cost-effective and efficient ways to produce high-quality prints on irregular shapes such as sports equipment and toy figurines. Direct-to-shape printing provides the flexibility, speed, and precision necessary to meet these demands while reducing lead times and costs.

Ink Type Insights

Ther UV-based segment dominated the market in 2024, accounting for a 48.9% share. UV-based ink technology is expanding rapidly in the direct to shape printer market due to its ability to cure ink instantly using ultraviolet light, allowing for high-quality, durable prints on various surfaces. This technology is especially beneficial for industries that require fast production cycles and long-lasting prints, such as automotive and electronics. UV-based inks also offer the advantage of being more environmentally friendly than solvent-based inks, further driving their adoption in applications that require sustainability and efficiency.

Solvent-based inks are a popular choice in the direct to shape printer market due to their ability to produce durable, vibrant prints on a wide range of materials. These inks are particularly suited for applications that demand resistance to weathering, abrasion, and chemicals, making them ideal for industries such as packaging, automotive, and outdoor signage. As the demand for long-lasting, high-performance prints continues to rise, solvent-based inks remain a key driver of market growth, especially in industries with high durability requirements.

Type Insights

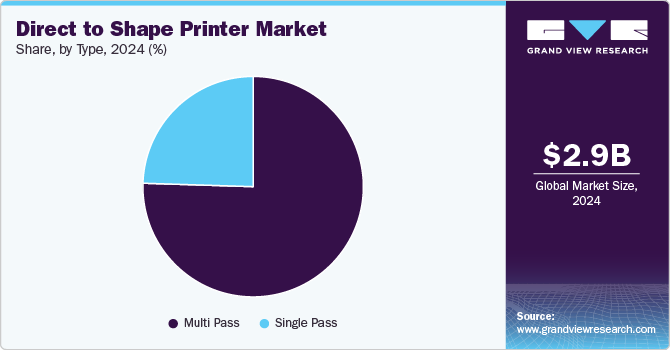

The Single Pass segment dominated the market in 2024, accounting for a 75.5% share driven by their high-speed printing capabilities, allowing for faster production cycles and increased efficiency in industries like packaging, automotive, and consumer goods. This technology allows printing on a variety of shapes and sizes in a single pass, significantly reducing processing time and cost per unit. As manufacturers seek to improve productivity and meet the growing demand for customized products, single-pass technology is becoming a preferred choice for mass production and on-demand printing applications.

Multi-pass direct to shape printers continue to be in demand due to their ability to produce highly detailed and high-resolution prints, making them ideal for applications that require fine detailing, such as cosmetics and electronics. While slower than single-pass technology, multi-pass printers offer enhanced quality and precision, which is crucial for industries where intricate designs and color accuracy are essential. The growing trend for premium and customizable products across various sectors is driving the adoption of multi-pass printing technologies.

Regional Insights

North America direct to shape printer market is fueled by the presence of advanced manufacturing facilities, technological innovation, and a strong demand for personalized products. The automotive and consumer electronics industries are leading adopters of these printers. Additionally, the region's strong focus on sustainability and eco-friendly practices drives the demand for efficient and waste-reducing manufacturing methods like direct to shape printing.

U.S. Direct to Shape Printer Market Trends

The direct to shape printer market in the U.S. is projected to expand at a CAGR of 9.5% over the forecast period, driven by the increasing demand for customization in industries like food & beverage, automotive, and consumer goods. The presence of a well-established manufacturing base, combined with a focus on technological innovation and sustainability, fuels market growth. Additionally, the demand for eco-friendly printing solutions and quick turnaround times in the packaging industry are contributing to the expansion of the market.

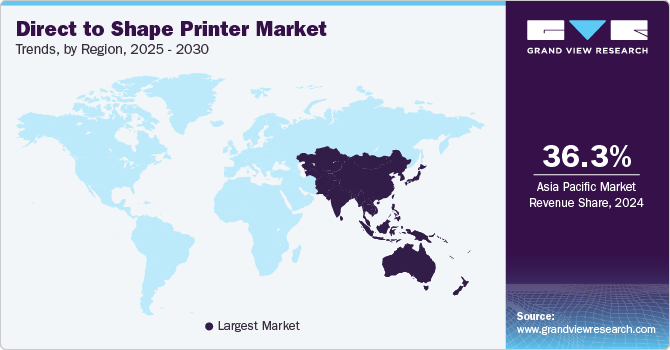

Asia Pacific Direct to Shape Printer Market Trends

The direct to shape printer market in Asia Pacific dominated in terms of global revenue share accounting for 36.3% of the market share in 2024. The region’s market is experiencing rapid market growth due to the strong manufacturing base in countries like China and India. The region has seen increased adoption of direct to shape printing technologies due to a rise in the demand for customized products across multiple sectors. Additionally, the growth of the e-commerce industry and demand for personalized packaging are further contributing to the rise in demand for direct to shape printers. Cost advantages and growing investments in research and development also bolster the market in this region.

China direct to shape printer market is expected to grow at a CAGR of 11.3% over the forecast period. China’s direct to shape printer market is driven by its massive manufacturing sector, particularly in electronics, automotive, and packaging industries. The country's focus on increasing production efficiency and customization, along with government initiatives to reduce environmental impact, is accelerating the adoption of advanced printing technologies. The shift towards industrial automation and high-quality printing is also contributing to market growth.

The direct to shape printer market in India is expected to grow at a CAGR of 11.7% over the forecast period. In India, the growing demand for personalized products, particularly in consumer goods and packaging, is a major factor driving the market for direct to shape printers. The rapid growth of the manufacturing sector and the increasing focus on improving production efficiency are fueling the adoption of these technologies. Additionally, the push for more sustainable manufacturing processes in line with environmental regulations supports market expansion.

Europe Direct to Shape Printer Market Trends

The direct to shape printer market in Europe is driven by a combination of technological advancements and the region’s strong industrial base. Countries in Europe have a growing demand for custom packaging and personalized consumer goods, particularly in industries such as fashion, automotive, and food. European manufacturers are increasingly looking for cost-effective solutions to reduce waste and improve production efficiency, making direct to shape printing attractive.

Spain direct to shape printer market is projected to expand at a CAGR of 11.2% over the forecast period. In Spain, market growth is driven by the strong demand for personalized packaging, particularly in the food and beverage sector. The country’s focus on improving sustainability and reducing waste is also pushing the adoption of direct to shape printing technologies. The increasing popularity of eco-friendly inks and the shift toward on-demand production are key drivers in this market

The direct to shape printer market in Italy is projected to expand at a CAGR of 10.7% over the forecast period. Italy's direct to shape printer market is supported by the high demand for customized designs in industries like automotive, fashion, and food & beverage. The country's strong emphasis on craftsmanship and aesthetic appeal drives the need for high-quality, precision printing technologies. Additionally, the adoption of advanced printing methods that reduce material waste is helping propel market growth.

Latin America Direct to Shape Printer Market Trends

The direct to shape printer market in Latin America is expanding as more manufacturers adopt advanced production technologies to meet the demand for customized and personalized products. While the adoption rate is slower compared to other regions, growing demand in sectors like automotive, consumer goods, and packaging is expected to boost market growth. Additionally, increasing government support for technological advancements and infrastructure development is creating favorable conditions for market expansion.

Brazil direct to shape printer market is projected to grow at a CAGR of 10.2% over the forecast period driven by the demand for high-quality, customized prints in industries like food & beverage, automotive, and packaging. The increasing need for efficient, cost-effective production methods and the growing trend toward sustainable manufacturing practices are contributing to the rise of direct to shape printing technologies. The country’s expanding middle class also drives demand for unique and customized consumer products.

Middle East & Africa Direct to Shape Printer Market Trends

The direct to shape printer market in the Middle East and Africa is driven by rapid industrialization and technological adoption in the region, particularly in countries like the UAE and Saudi Arabia. The demand for personalized products and custom packaging is on the rise, and direct to shape printing solutions offer an efficient method of meeting these needs. Furthermore, investment in smart manufacturing and innovation in local industries is helping to drive market expansion.

Saudi Arabia direct to shape printer market is projected to expand at a CAGR of 10.3% over the forecast period. The country’s growing emphasis on diversifying the economy and investing in manufacturing industries, such as automotive, packaging, and consumer goods, is driving market growth. The country’s push for technological innovation, along with the need for high-quality, durable prints in extreme conditions, supports the adoption of direct to shape printers. Additionally, increasing demand for eco-friendly solutions and efficient production processes is further boosting market prospects.

Key Direct To Shape Printer Company Insights

Some of the key players operating in the market include HP Development Company, L.P. and Canon Inc. among others.

-

HP Development Company, L.P. is a global company specializing in personal computers, printers, and related supplies. The company operates in over 170 countries and is committed to advancing technology that drives positive change in society.The company invests significantly in research and development and has a diverse portfolio that includes laptops, desktops, printers, and accessories and serves a wide range of customers from individual consumers to large enterprises.

-

Canon Inc. is a global provider of imaging and optical products, renowned for its innovative digital imaging solutions. Its portfolio includes a wide range of products such as printers, multifunction devices, and medical imaging equipment. The company operates in various sectors, catering to both consumer and business markets.

Key Direct To Shape Printer Companies:

The following are the leading companies in the direct to shape printer market. These companies collectively hold the largest market share and dictate industry trends.

- HP Development Company, L.P.

- Canon Inc.

- Xerox Corporation

- Durst Group

- EFI (Electronics For Imaging, Inc.)

- Mimaki Engineering Co., Ltd.

- Roland DG Corporation

- Ricoh Company, Ltd.

- Seiko Epson Corporation

- Konica Minolta, Inc.

- Agfa-Gevaert Group

- Xaar plc

- Inca Digital Printers Ltd.

- Kornit Digital Ltd.

- Stratasys Ltd.

- 3D Systems Corporation

- Markforged, Inc.

- Voxeljet AG

- Brother Industries, Ltd.

Recent Developments

-

In March 2024, FUJIFILM Europe GmbH introduced an inkjet ink technology named AQUAFUZE, which merges UV-curable and water-based ink properties for wide-format printing. THE UV-curable aqueous ink is designed for indoor applications like signage and wallpaper, offering advantages such as reduced printhead clogging, strong substrate adhesion without primers, a glossy finish, and lower odor for enhanced safety. The introduction of AQUAFUZE technology could significantly impact the direct to shape printing market by providing inks that meet the growing demand for durability and versatility in printing on complex surfaces. Its compatibility with various substrates and robust performance characteristics may broaden the application scope for direct to shape printers, facilitating advancements in customization and efficiency.

-

In April 2024, Velox Ltd., a company specializing in direct to shape digital decoration solutions, secured USD 38 million in funding led by Fortissimo Capital. This investment aims to accelerate Velox's global expansion and further innovation in high-speed digital printing for rigid packaging containers, particularly in the beverage can market. Fortissimo Capital plans to scale the company's production and capitalize on the growing demand for more sustainable and efficient printing technologies.

Direct To Shape Printer Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2025 |

USD 3.23 billion |

|

Revenue forecast in 2030 |

USD 5.33 billion |

|

Growth rate |

CAGR of 10.5% from 2025 to 2030 |

|

Base year for estimation |

2024 |

|

Historical data |

2018 - 2023 |

|

Forecast period |

2025 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2025 to 2030 |

|

Report coverage |

Revenue forecast, company market position analysis, competitive landscape, growth factors, and trends |

|

Segments covered |

Technology, end-use, ink type, type, region |

|

Regional scope |

North America; Europe; Asia Pacific; Latin America; and Middle East & Africa |

|

Country Scope |

U.S.; Canada; Mexico; UK; Germany; France; Italy; Spain; China; India; Japan; South Korea; Australia; Brazil; Argentina; South Africa; Saudi Arabia; UAE |

|

Key companies profiled |

HP Development Company, L.P.; Canon Inc.; Xerox Corporation; Durst Group; EFI (Electronics For Imaging, Inc.); Mimaki Engineering Co., Ltd.; Roland DG Corporation; Ricoh Company, Ltd.; Seiko Epson Corporation; Konica Minolta, Inc.; Agfa-Gevaert Group; Xaar plc; Inca Digital Printers Ltd.; Kornit Digital Ltd.; Stratasys Ltd.; 3D Systems Corporation; Markforged, Inc.; Voxeljet AG; Brother Industries, Ltd. |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Direct to Shape Printer Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global direct to shape printer market report on the basis of technology, end-use, ink type, type, and region:

-

Technology Outlook (Revenue, USD Million, 2018 - 2030)

-

Inkjet

-

Laser

-

Others

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Cosmetics & Personal Care

-

Automotive

-

Electronics

-

Food & Beverage

-

Toys & Sporting Goods

-

Others

-

-

Ink Type Outlook (Revenue, USD Million, 2018 - 2030)

-

UV-based

-

Solvent-based

-

Aqueous-based

-

-

Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Single Pass

-

Multi Pass

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

France

-

Germany

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

India

-

Japan

-

South Korea

-

Australia

-

-

Latin America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

Saudi Arabia

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global direct to shape printer market size was estimated at USD 2.92 billion in 2024 and is expected to reach USD 3.23 billion in 2025.

b. The global direct-to-shape printer market, in terms of revenue, is expected to grow at a compound annual growth rate of 10.5% from 2025 to 2030 to reach USD 5.33 billion by 2030..

b. The market in Asia Pacific dominated the market in 2024 accounting for 36.3% of the global revenue share driven by rapid industrialization, increasing demand for personalized packaging, and advancements in manufacturing technologies. The rising adoption of direct-to-shape printing solutions across industries like automotive, food & beverage, and electronics is further boosting market expansion.

b. Some of the key players operating in the direct-to-shape printer market are HP Inc., Canon Inc., Xerox Corporation, Durst Group, EFI (Electronics For Imaging, Inc.), Mimaki Engineering Co., Ltd., Roland DG Corporation, Ricoh Company, Ltd., Seiko Epson Corporation, Konica Minolta, Inc., Agfa-Gevaert Group, Xaar plc, Inca Digital Printers Ltd., Kornit Digital Ltd., Stratasys Ltd., 3D Systems Corporation, Markforged, Inc., Voxeljet AG, Hewlett-Packard Development Company, L.P., and Brother Industries, Ltd.

b. The direct-to-shape printer market is driven by the increasing demand for customized and high-quality prints across industries like packaging, automotive, and consumer goods. Technological advancements in printing technology, such as improved efficiency and eco-friendly solutions, further fuel market growth.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."