Ceramic Textile Market Size, Share & Trends Analysis Report By Type (Vitreous Alumina-Silica, Polycrystalline Ceramic Fiber), By End-use (Transportation, Petrochemical, Power Generation, Iron & Steel), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-4-68040-452-3

- Number of Report Pages: 109

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2022

- Forecast Period: 2024 - 2030

- Industry: Advanced Materials

Ceramic Textile Market Size & Trends

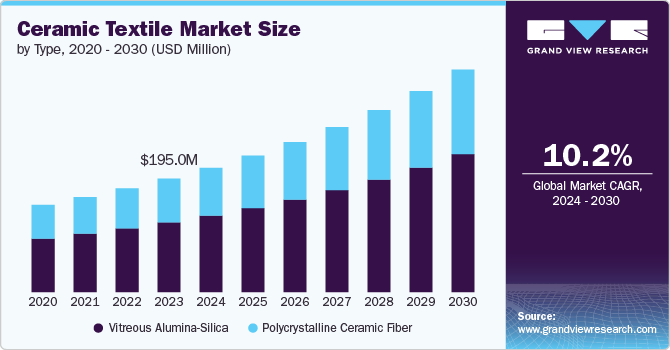

The global ceramic textile market size was estimated at USD 195 million in 2023 and is projected to grow at a CAGR of 10.2% from 2024 to 2030. This growth is attributed to their superior thermal resistance, durability, and insulation properties, which make them a preferable choice for high-temperature applications. Industries, including petrochemicals, aerospace, and power generation, are increasingly adopting ceramic textiles for use in insulation, fire protection, and heat shields, as they can withstand extreme temperatures without deteriorating. Their ability to provide thermal insulation while being lightweight further enhances their appeal in applications where both performance and weight reduction are critical, such as in aircraft and industrial furnaces.

The shift toward sustainable and energy-efficient technologies is further anticipated to drive the demand for ceramic textiles. Industries are aiming to reduce energy consumption and carbon emissions, and ceramic textiles play a critical role in enhancing thermal efficiency, minimizing heat loss, and enhancing operational safety. The growing awareness of the environmental benefits of ceramic textiles, coupled with stringent government regulations on energy efficiency and workplace safety, is likely to boost their adoption across various industrial sectors globally.

The market is hampered by high production costs and limited flexibility compared to traditional materials. The manufacturing process of ceramic fibers involves complex techniques and expensive raw materials, which is expected to increase the overall cost, making them less accessible for widespread use in certain industries. Additionally, ceramic textiles, while offering excellent thermal resistance, can be brittle and less durable in applications requiring frequent bending or handling. These limitations, along with competition from more affordable alternatives like glass or polymer-based fibers, hinder the broader adoption of ceramic textiles in various sectors.

Advancements in technology are expected to improve performance flexibility and reduce production costs. Innovations include the development of more durable and flexible ceramic fibers, such as silicon carbide (SiC) and alumina fibers that enhance strength and thermal resistance while minimizing brittleness. Advanced manufacturing techniques, such as chemical vapor deposition (CVD) and sol-gel processes, are being used to manufacture finer and more uniform ceramic textiles.

Type Insights

Based on type, vitreous alumina silica fiber dominated the market with a revenue share of 61.5% in 2023 and is further expected to grow at a significant rate over the forecast period. The market is driven by its excellent thermal insulation properties and resistance to high temperatures, making it a preferred material in industries such as petrochemicals, power generation, and metallurgy. In addition, the increasing focus on energy conservation and sustainability is boosting the adoption of high-performance insulation materials like vitreous alumina silica fibers, which help reduce heat loss and improve energy efficiency in industrial processes.

The demand for polycrystalline ceramic fiber is expected to grow at a significant rate over the forecast period. The demand for polycrystalline ceramic fiber is driven by the growing emphasis on lightweight materials in industries like automotive and aerospace. PCF's ability to provide insulation while being lightweight makes it a valuable solution for improving fuel efficiency and reducing carbon emissions.

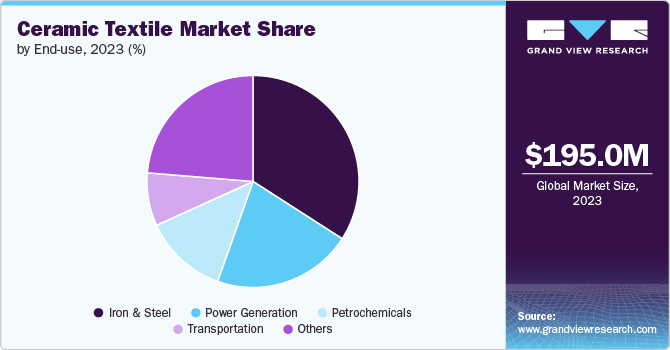

End-use Insights

Based on end use, the iron & steel segment accounted for the largest revenue share of 34.1% in 2023. The demand in this sector is driven by the rising need for materials that can withstand extreme conditions while improving process efficiency and reducing maintenance costs. With the industry continuing to focus on upgrading technologies and improving production efficiency, the use of advanced ceramic textiles is expected to grow in the coming years.

Transportation applications are anticipated to grow at a significant rate over the forecast period. Ceramic textiles are increasingly utilized for their heat-resistant and lightweight properties, which are crucial for enhancing fuel efficiency and safety. They are used in applications such as insulation in high-performance engines and exhaust systems. The demand in this sector is growing as automotive manufacturers seek advanced materials to meet stringent emissions standards and enhance vehicle performance. Additionally, the rise in electric vehicles, which require efficient thermal management, is further driving the use of ceramic textiles.

Regional Insights

North America ceramic textile market dominated the global industry with a revenue share of 38.5% in 2023. The demand for ceramic textiles is expected to rise owing to the region's strong focus on advanced manufacturing technologies and high-performance materials in industries such as aerospace, defense, and automotive. The growing emphasis on improving energy efficiency and meeting stringent environmental regulations is driving the adoption of ceramic textiles for applications like thermal insulation and protective gear.

U.S. Ceramic Textile Market Trends

The ceramic textile market in the U.S. is expected to grow at a CAGR of 10.4% over the forecast period. The U.S. market is driven by the rising demand for ceramic textiles due to the country's large industrial base and increasing requirements for high-temperature applications and protective materials. The U.S. defense and aerospace sectors are key drivers of this increased demand, as ceramic textiles offer superior thermal protection and durability. Furthermore, the push toward sustainable and energy-efficient solutions in various industries, combined with government regulations on emissions and safety, is expected to contribute to the growth of the ceramic textiles market in the U.S.

Europe Ceramic Textile Market Trends

The ceramic textile market in Europe is expected to grow at a CAGR of 10.0% from 2024-2030. The demand for ceramic textiles is growing due to the region's strong industrial sector and commitment to technological innovation and environmental sustainability. European industries, such as automotive, aerospace, and energy, are increasingly adopting the product for its excellent thermal insulation and protective properties, thereby boosting the product’s demand in the coming years.

Asia Pacific Ceramic Textile Market Trends

The ceramic textile market in Asia Pacific is expected to grow at the highest CAGR over the forecast period. Rapid industrialization, urbanization, and significant investments in infrastructure development., particularly in China, India, and Southeast Asia, is expected to drive the demand for ceramic textile. The growing focus on improving industrial safety and reducing environmental impact is accelerating the adoption of ceramic textiles which are expanding their industrial capabilities and adhering to stricter safety standards.

Key Ceramic Textile Company Insights

Some of the key players operating in the market include the 3M Company. and Morgan Advanced Materials Corporation.

-

The 3M Company was incorporated in 1929 and is headquartered in Minnesota, U.S. The company offers products to a wide range of end-use companies, including cleaning & protecting, personal healthcare, home care, decoration, school supplies, office supplies, and sports & recreation. The company operates its business through five business segments, namely industrial, safety and graphics, healthcare, electronics and energy, and consumer.

-

Morgan Advanced Materials Corporation is engaged in designing and manufacturing of thermal products, performance carbon, and technical ceramics for a wide range of industries including, energy, transportation, petrochemical & chemical, and security and defense. The company has about 70 manufacturing facilities which are spread across 20 countries.

Kyocera Corporation and Isolite Insulating Products Co., Ltd. are some of the emerging participants in the market.

-

Kyocera Corporation is a Japanese multinational company founded in 1959, specializing in the production of a wide range of high-tech materials and electronic components. Kyocera operates across several industries, including electronics, telecommunications, automotive, and renewable energy. The company is known for its advanced ceramics technologies, which are used in various applications such as semiconductors, medical devices, and industrial equipment. In addition to its materials and components business, Kyocera also manufactures consumer products like printers, copiers, and mobile phones.

-

Isolite Insulating Products Co., Ltd. is involved in the production of high-performance insulating materials, primarily for industrial applications. Isolite is a leading manufacturer of ceramic fiber products, refractory materials, and thermal insulation solutions. The company’s product portfolio includes ceramic fiber boards, blankets, and modules designed to withstand extreme heat, reduce energy consumption, and improve operational efficiency. The company serves a wide range of industries, including steel, petrochemical, automotive, and energy sectors, where high-temperature insulation is crucial.

Key Ceramic Textile Companies:

The following are the leading companies in the ceramic textile market. These companies collectively hold the largest market share and dictate industry trends.

- 3M Company

- Morgan Advanced Materials Corporation

- Ibiden Co. Ltd.

- Isolite Insulating Products Co. Ltd.

- Kyocera Corporation

- Luyang Energy-Saving Materials Co. Ltd.

- Rath Inc.

- Unifrax Corporation

- Rauschert Steinbach GmbH

- Zircar Zirconia

Ceramic Textile Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 213.5 million |

|

Revenue forecast in 2030 |

USD 382.0 million |

|

Growth Rate |

CAGR of 10.2% from 2024 to 2030 |

|

Base year for estimation |

2023 |

|

Historical data |

2018 - 2022 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, competitive landscape, growth factors, and trends |

|

Segments covered |

Type, end-use, region |

|

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

|

Country scope |

U.S., Canada, Mexico, UK, Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina |

|

Key companies profiled |

3M Company; Morgan Advanced Materials Corporation; Ibiden Co. Ltd.; Isolite Insulating Products Co. Ltd.; Kyocera Corporation; Luyang Energy-Saving Materials Co. Ltd.; Rath Inc.; Unifrax Corporation; Rauschert Steinbach GmbH; Zircar Zirconia |

|

Customization scope |

Free report customization (equivalent up to 8 analysts orking days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Ceramic Textile Market Report Segmentation

This report forecasts revenue growth at global, regional & country levels and provides an analysis of the latest industry trends in each of the segments from 2018 to 2030. For this study, Grand View Research has segmented the global ceramic textile market report on the basis of type, end-use, and region:

-

Type Outlook (Revenue, USD Million, 2018 - 2030)

-

Vitreous Alumina-Silica

-

Polycrystalline Ceramic Fiber

-

-

End-use Outlook (Revenue, USD Million, 2018 - 2030)

-

Transportation

-

Petrochemicals

-

Iron and Steel

-

Power Generation

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

Spain

-

-

Asia Pacific

-

China

-

Japan

-

India

-

South Korea

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

Frequently Asked Questions About This Report

b. The global ceramic textile market size was estimated at USD 195 million in 2023 and is expected to reach USD 213.5 million in 2024.

b. The global ceramic textile market is expected to grow at a compound annual growth rate (CAGR) of 10.2% from 2024 to 2030 to reach USD 382.0 million by 2030.

b. Vitreous alumina-silica accounted for the largest revenue share of over 61.5% in 2023. The marker is driven by its excellent thermal insulation properties and resistance to high temperatures, making it a preferred material in industries such as petrochemical, power generation, and metallurgy.

b. Some key players operating in the ceramic textile market include 3M Company, Morgan Advanced Materials Corporation, Ibiden Co. Ltd., Isolite Insulating Products Co. Ltd., Kyocera Corporation, Luyang Energy-Saving Materials Co. Ltd., Rath Inc., Unifrax Corporation, Rauschert Steinbach GmbH, Zircar Zirconia.

b. The key factors that are driving the market growth are their superior thermal resistance, durability, and insulation properties, which make them preferable choice for high-temperature applications.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."