3D Printing Ceramics Market Size, Share & Trends Analysis Report By End Use (Medical, Aerospace, Industrial Machinery), By Region (North America, Europe, Asia Pacific), By Vendor Landscape, And Segment Forecasts, 2025 - 2030

- Report ID: GVR-3-68038-464-2

- Number of Report Pages: 90

- Format: PDF

- Historical Range: 2018 - 2023

- Forecast Period: 2025 - 2030

- Industry: Advanced Materials

3D Printing Ceramics Market Size & Trends

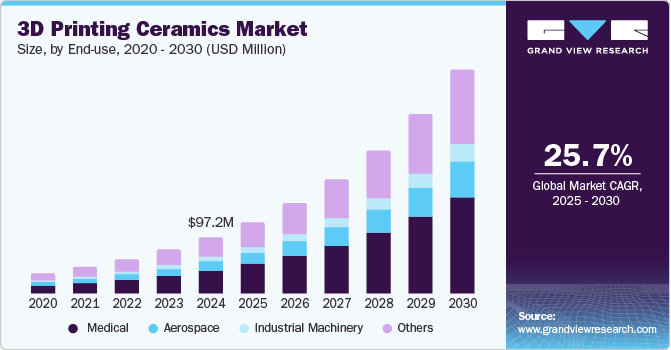

The global 3D printing ceramics market size was valued at USD 97.2 million in 2024 and is expected to grow at a CAGR of 25.7% from 2025 to 2030. This growth can be attributed to technological advancements, offering high precision and customization for complex aerospace, healthcare, and automotive designs. The demand for lightweight, durable, and heat-resistant materials further fuels adoption. Furthermore, the rising need for rapid prototyping and the ability to create intricate structures with minimal material waste are key factors. Increasing research investments and innovations in ceramic materials, such as non-oxide ceramics, also contribute significantly to market expansion.

3D printing ceramics involves using additive manufacturing to create three-dimensional objects from ceramic materials. This method layers’ fine ceramic powders or pastes to form objects, which are then heated to high temperatures to strengthen and solidify them. Compared to traditional ceramic production, 3D printing offers greater precision, intricate designs, and the ability to create customized shapes that would be challenging with conventional methods. The process is particularly valuable in industries such as healthcare, where it is used for personalized implants and prosthetics, and aerospace, where it’s used for components requiring durability and heat resistance. 3D-printed ceramics are also sought after for consumer products due to their strength, heat tolerance, and biocompatibility.

One major factor driving the demand for 3D-printed ceramics is the need for customization. There is a growing need for individualized medical solutions, including custom prosthetics, dental implants, and orthopedic devices in the healthcare sector. 3D printing allows the production of ceramics tailored to specific patient requirements, ensuring better fit and function. This ability to create personalized solutions is a significant market driver.

Furthermore, the continuous advancement of printing technologies, such as binder jetting and laser sintering, has made ceramic printing more efficient, precise, and cost-effective. With speed, material quality, and consistency improvements, industries such as aerospace, automotive, and healthcare are increasingly adopting 3D-printed ceramics for their unique properties and applications.

Moreover, market growth opportunities also lie in the aerospace and automotive industries. Both sectors require lightweight, high-strength, and heat-resistant materials for components such as turbine blades, exhaust systems, and heat shields. 3D printing offers an advantage by enabling the creation of complex parts that are difficult to manufacture using traditional techniques. This is pushing industries to adopt this technology, thereby driving market growth.

End Use Insights

The medical end use segment dominated the global 3D printing ceramics industry with the highest revenue share of 40.9% in 2024. This growth can be attributed to the increasing demand for personalized healthcare solutions. In addition, 3D printing allows for custom implants, prosthetics, and dental devices tailored to individual patient needs, ensuring better fit and functionality. Furthermore, the high biocompatibility and strength of 3D-printed ceramics make them ideal for medical applications, improving treatment outcomes and expanding the use of ceramics in medical devices, particularly in orthopedics and dentistry.

The aerospace segment is expected to grow at a CAGR of 25.8% over the forecast period, owing to the demand for lightweight, heat-resistant, and durable materials. In addition, the ability to produce complex, geometrically optimized components such as turbine blades, heat shields, and exhaust parts is a significant advantage. Furthermore, 3D printing enables the production of parts that traditional manufacturing methods cannot achieve, contributing to enhanced performance and efficiency in aircraft and spacecraft.

Regional Insights

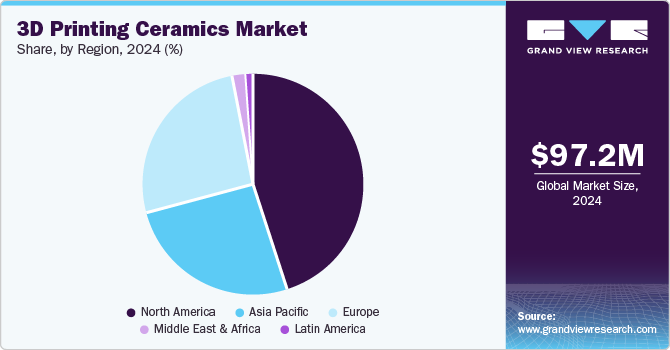

The North America 3D printing ceramics market dominated the global market and accounted for the largest revenue share of 45.5% in 2024, primarily driven by strong technological advancements and high adoption rates across industries such as aerospace, healthcare, and automotive. In addition, the region's focus on innovation, research, and development in additive manufacturing has led to the widespread use of 3D-printed ceramics. Furthermore, the growing demand for customized medical devices and components in aerospace pushes the market forward, with businesses seeking efficient, sustainable, cost-effective manufacturing solutions.

U.S. 3D Printing Ceramics Market Trends

The 3D printing ceramics market in the U.S. led the North American market and held a significant share in 2024 due to the country’s leadership in technological advancements and its robust healthcare sector. The U.S. is witnessing substantial demand for personalized medical implants and prosthetics, spurring innovation in ceramic materials. In addition, the aerospace industry, known for its high-performance requirements, is also driving the adoption of 3D-printed ceramics for producing lightweight, heat-resistant components. Furthermore, increasing research and investments in additive manufacturing technologies contribute to the market's expansion.

Asia Pacific 3D Printing Ceramics Market Trends

The Asia Pacific 3D printing ceramics market is expected to grow at a CAGR of 27.0% from 2025 to 2030, owing to the increasing industrialization and technological advancements. Countries such as Japan, South Korea, and India are embracing 3D printing for aerospace, automotive, and healthcare applications. In addition, the demand for customized medical devices and the need for lightweight, durable components in industries such as aerospace is pushing the market forward. Furthermore, the region's growing focus on sustainable manufacturing practices contributes to adopting 3D printing ceramics.

The 3D printing ceramics market in China held the dominant position in the Asia Pacific market, with the largest revenue share in 2024, driven by the country’s heavy investments in research and development, particularly in advanced manufacturing technologies. In addition, the aerospace and automotive industries in China are increasingly using 3D-printed ceramics to produce complex, high-performance components, thereby driving market growth. Furthermore, the healthcare sector also plays a significant role, with a rising demand for personalized medical implants and prosthetics, boosting the country's market expansion.

Europe 3D Printing Ceramics Market Trends

Europe 3D printing ceramics market is expected to grow significantly over the forecast period, primarily driven by the region's emphasis on sustainability and innovation. Aerospace, automotive, and healthcare industries are increasingly adopting 3D-printed ceramics for their lightweight and durable properties. In addition, the demand for customized medical devices and efficient manufacturing solutions is fueling growth. Furthermore, Europe’s strong industrial base and continuous advancements in 3D printing technologies are creating opportunities for expanding the use of ceramics in various high-performance applications.

The growth of the 3D printing ceramics market in Germany is expected to be driven by its strong industrial sector and focus on cutting-edge manufacturing technologies. The country’s aerospace and automotive industries are adopting 3D-printed ceramics to produce complex, lightweight, and heat-resistant components. Furthermore, Germany is increasingly using customized medical implants and prosthetics in healthcare. The combination of a highly skilled workforce, robust infrastructure, and ongoing research investments makes Germany a leader in the 3D printing ceramics market in Europe.

Key 3D Printing Ceramics Company Insights

Key companies in the 3D printing ceramics industry include Lithoz, 3D CERAM, Steinbach AG, and others. These players focus on continuous innovation, enhancing material capabilities, and expanding product offerings. They are also investing in strategic partnerships, technological advancements, and global expansion to strengthen market presence and meet evolving customer demands.

-

PRODWAYS delivers innovative solutions in aerospace, automotive, healthcare, and industrial applications. The company designs and manufactures 3D printing systems capable of producing complex ceramic parts with exceptional precision and material properties. Their expertise in additive manufacturing allows them to provide solutions that enhance efficiency, reduce costs, and enable the production of customized ceramic components for multiple sectors.

-

Steinbach AG specializes in additive manufacturing technologies for ceramics, offering advanced ceramic powders and materials suitable for 3D printing. The company operates in the industrial and manufacturing sectors, catering to applications that require precision and high-performance materials, including automotive, aerospace, and electronics.

Key 3D Printing Ceramics Companies:

The following are the leading companies in the 3d printing ceramics market. These companies collectively hold the largest market share and dictate industry trends.

- Lithoz

- 3D CERAM

- Tethon 3D

- PRODWAYS

- Steinbach AG

- Desamanera S.r.l.

- Additive Elements GmbH

- Emerging Objects

- Materialise

- Shapeways, Inc.

Recent Developments

-

In April 2024, MatterHackers completed the acquisition of Source Graphics and announced a new collaboration with Formlabs. This strategic move is designed to enhance MatterHackers’ 3D printing capabilities, offering an expanded range of solutions for professional and consumer markets. The partnership will allow both companies to provide innovative tools for various applications, including 3D printing ceramics. The acquisition strengthens MatterHackers' position in the 3D printing space, with a focus on supporting advanced material options.

-

In December 2023, Lithoz partnered with Oak Ridge National Laboratory (ORNL) to advance the development of 3D printing ceramics, specifically non-oxide ceramics, for extreme temperature applications. This collaboration aims to push the boundaries of ceramic materials in high-performance environments, such as the aerospace and energy sectors. The project will leverage Lithoz’s expertise in 3D printing ceramics and ORNL’s cutting-edge research facilities to create innovative solutions for industries requiring materials that can withstand extreme thermal conditions.

3D Printing Ceramics Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2025 |

USD 123.7 million |

|

Revenue forecast in 2030 |

USD 388.4 million |

|

Growth Rate |

CAGR of 25.7% from 2025 to 2030 |

|

Base year for estimation |

2024 |

|

Historical data |

2018 - 2023 |

|

Forecast period |

2025 - 2030 |

|

Quantitative units |

Volume in Kilograms, Revenue in USD Million, and CAGR from 2025 to 2030 |

|

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

|

Segments covered |

End use, region |

|

Regional scope |

North America, Asia Pacific, Europe, Latin America, Middle East and Africa |

|

Country scope |

U.S., Germany, UK, France, Italy, China, and Japan, |

|

Key companies profiled |

Lithoz; 3D CERAM; Tethon 3D; PRODWAYS; Steinbach AG; Desamanera S.r.l.; Additive Elements GmbH; Emerging Objects; Materialise; Shapeways, Inc. |

|

Customization scope |

Free report customization (equivalent to 8 analyst working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global 3D Printing Ceramics Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and analyzes the latest industry trends in each sub-segment from 2018 to 2030. For this study, Grand View Research has segmented the global 3D printing ceramics market report based on end use and region.

-

End Use Outlook (Volume, Kilograms; Revenue, USD Million, 2018 - 2030)

-

Aerospace

-

Medical

-

Industrial Machinery

-

Others

-

-

Regional Outlook (Volume, Kilograms; Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

-

Europe

-

Germany

-

UK

-

France

-

Italy

-

-

Asia Pacific

-

China

-

Japan

-

-

Latin America

-

Middle East and Africa

-

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."