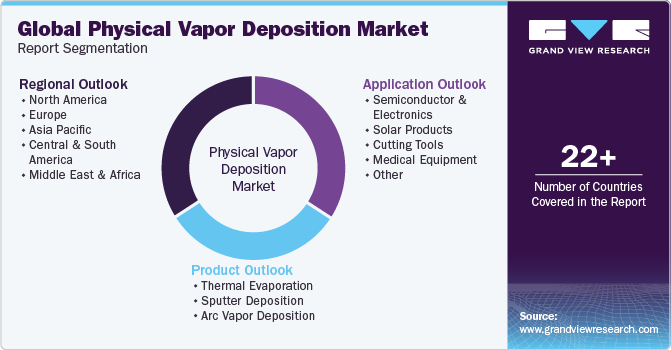

Physical Vapor Deposition Market Size, Share & Trends Analysis Report By Product (Sputter Deposition, Arc Vapor Deposition), By Application (Semiconductor & Electronics, Solar Products), By Region, And Segment Forecasts, 2024 - 2030

- Report ID: GVR-1-68038-085-9

- Number of Report Pages: 125

- Format: PDF, Horizon Databook

- Historical Range: 2018 - 2023

- Forecast Period: 2024 - 2030

- Industry: Bulk Chemicals

Physical Vapor Deposition Market Trends

The global physical vapor deposition market size was estimated at USD 3.0 billion in 2023 and is projected to grow at a CAGR of 7.6% from 2024 to 2030. Increasing demand for green energy solutions, such as solar photovoltaic cells, is expected to increase the demand for physical vapor deposition (PVD) coating services over the forecast period. Various countries have established new goals to tackle the increasing energy prices and decreasing availability of fossil fuels. Such initiatives are likely to encourage the installation of solar cells and drive the market growth.

In addition, the trend for green energy is expected to grow over the forecast period owing to the environmental benefits and advantages and positive perceptions of consumers pertaining to solar photovoltaic cells. The rising manufacturing of solar photovoltaic cells is likely to create demand for physical vapor deposition over the forecast period.

Physical vapor deposition offers an excellent alternative to chrome plating. PVD-based coatings as hard chrome replacements for various industrial applications in automotive components such as pumps, bearings, and actuators. In March 2024, traditional chrome plating in Europe is likely to be banned by the end of 2024. Many automakers in the European region are expected to shift toward safe and environmentally friendly coating technologies such as PVD coating. This is expected to increase the demand for physical vapor deposition services over the forecast period.

Moreover, the rise in the global demand for consumer electronics can be attributed to the increasing per capita disposable income and high demand for advanced electronics. The surging adoption of electronic products for workplaces, daily use, and entertainment is expected to increase the global demand for semiconductors. This is anticipated to drive the demand for PVD equipment and services for the semiconductor fabrication process.

According to the National Health Expenditure Data, U.S. Medicare spending increased by 8.4% to USD 900 billion in 2021. Moreover, Medicaid spending increased by 9.2% to USD 734 billion compared to 2020. Furthermore, in 2021, the U.S. spending for medicines increased by 12% due to increased demand for COVID vaccines, boosters, treatments, and prescription medication usage was 194 billion daily doses across the U.S. These aforementioned factors are expected to drive the demand for physical vapor deposition in the medical sector over the forecast period.

According to the Semiconductor Industry Association, Taiwan, South Korea, Japan, and China accounted for a 72% of the global semiconductor production in 2022, with its previous manufacturing hubs such as the U.S. and Japan focusing on the highly profitable countries for exporting their products. Moreover, as of 2022, the region was the largest semiconductor market in the world, with China being the largest consumer of semiconductors in Asia Pacific. In December 2022, Taiwan Semiconducting Manufacturing Co. announced an increase in its investments to enhance its manufacturing capacity in the U.S., signaling a shift in the geographic dynamics of the sector. Thus, the growing semiconductor industry globally is expected to drive the market demand over the forecast period. PVD is crucial in the semiconductor industry for precisely depositing thin films on silicon wafers, enabling the fabrication of advanced integrated circuits and microelectronic devices.

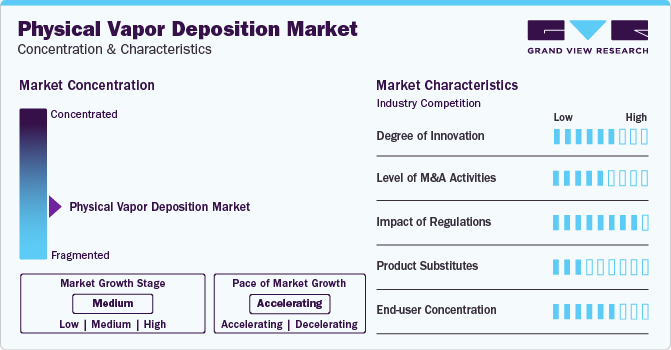

Market Concentration & Characteristics

The market growth stage is medium and the pace of growth is accelerating. The physical vapor deposition market is characterized by a high degree of innovation owing to rapid technological advancements. Moreover, companies are further adopting various organic and inorganic growth strategies, such as expansions, mergers and acquisitions, investments, and product launches, to strengthen their position in the global market.

The PVD market is characterized by dynamic and evolving trends that reflect its widespread applications and technological advancements. With a foundation in thin-film deposition, the PVD market spans a diverse range of industries, including semiconductors, electronics, medical devices, aerospace, automotive, and renewable energy.

Moreover, technological innovation remains a hallmark, with ongoing advancements in coating materials and deposition processes, driving improvements in efficiency and precision. The semiconductor industry stands out as a primary driver, demanding sophisticated PVD techniques for the fabrication of integrated circuits and microelectronic devices. In addition, the focus on renewable energy sources, especially in solar applications, fuels the demand for PVD coatings to enhance the efficiency and durability of solar panels. Furthermore, the medical sector increasingly relies on PVD for biocompatible coatings in devices. As industries prioritize surface engineering and environmental considerations, PVD plays a crucial role in providing tailored solutions for wear resistance, corrosion protection, and aesthetic finishes.

The market exhibits a high initial capital investment for establishing PVD coating facilities, contributing to entry barriers, and shaping a competitive landscape. Moreover, the customization and specialization of PVD solutions, along with a global industrial expansion, underscore the diverse and growing nature of the market, offering stakeholders opportunities for innovation and strategic positioning. Overall, the PVD market is characterized by its adaptability to diverse applications, continual technological evolution, and its integral role in enhancing the performance and longevity of various products across industries.

Product Insights

The sputter deposition product segment led the market and accounted for 47.6% of the global revenue in 2023. Sputter deposition, a widely used PVD technique, offers numerous advantages, and finds diverse applications across industries. A significant driver for the segment growth is the widespread applicability and versatility of the sputtering deposition method in various industries. This method enables a highly precise and controlled deposition of thin films of diverse materials onto substrates, thereby making sputtering deposition indispensable in semiconductor production, display technologies, optics, and solar cells.

Arc vapor deposition enables the development of better-quality coatings than other PVD techniques owing to its ability to generate dense and uniform coating layers. The increasing demand for products with enhanced performance, durability, and functionality drives the adoption of multifunctional coatings produced using the arc vapor deposition technique. As industries worldwide strive to meet evolving consumer preferences and regulatory requirements, the development of coatings with multiple properties stimulates the demand for arc vapor deposition technology and drives innovations in multifunctional coating development.

Application Insights

The semiconductor & electronics application segment led the market in terms of revenue in 2023. The increasing investments in semiconductor manufacturing worldwide are expected to significantly enhance the demand for physical vapor deposition (PVD) technologies worldwide. As semiconductor devices continue to advance in terms of complexity and performance, the requirement for precise and high-quality thin-film deposition processes, such as PVD becomes paramount. PVD techniques offer unparalleled control over the thickness, composition, and properties of films, thereby making them indispensable for fabricating integrated circuits, microprocessors, memory chips, and other semiconductor components.

PVD is widely employed to deposit anti-reflective coatings on the glass surfaces of solar panels. These coatings minimize reflection and enhance light absorption by the solar cells, improving the overall efficiency of the solar panel. Materials such as silicon nitride (SiNx) are commonly used for anti-reflective coatings. PVD is used to deposit back contacts on the rear side of solar cells. Back contacts play a crucial role in extracting the generated electrical current from the solar cell. PVD ensures precise deposition of conductive materials for efficient electrical performance. These aforementioned factors are expected to propel the market growth over the forecast period.

Regional Insights

The physical vapor deposition market in North America is expected to grow at a CAGR of 7.5% over the forecast period. PVD is a widely used technology in various industries for applying thin films and coatings to surfaces. The PVD market in North America has shown significant growth, driven by several factors and applications across diverse sectors. The electronics industry heavily relies on PVD techniques for thin-film deposition, particularly in the manufacturing of semiconductors and various electronic components.

U.S. Physical Vapor Deposition Market Trends

The U.S. market is expected to grow at a 7.4% CAGR from 2024 to 2030. The demand for PVD is further amplified by the global surge in consumer electronics, electric vehicles, and renewable energy technologies, all of which rely heavily on semiconductors. As a result, the PVD market is experiencing robust growth, fueled by the expansion of the semiconductor industry and the ongoing innovation in electronic devices.

The physical vapor deposition market in Canada is expected to grow at a CAGR of 7.8% from 2024 to 2030. According to the International Trade Administration, in 2022, the medical device market size in Canada was estimated to be USD 6.8 billion. Furthermore, in 2022, total healthcare spending in Canada was approximately USD 244.27 billion. These aforementioned factors are expected to increase the demand for PVD over the forecast period.

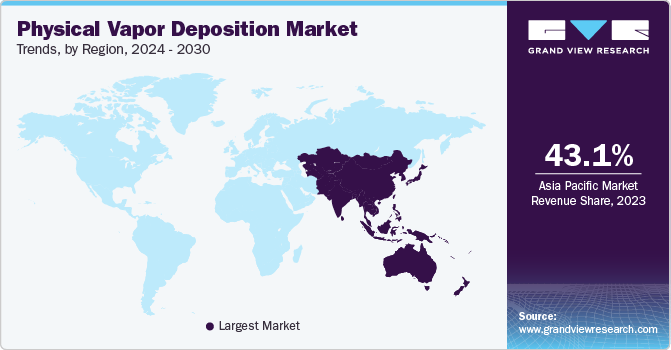

Asia Pacific Physical Vapor Deposition Market Trends

Asia Pacific dominated the market and accounted for 43.1% share in 2023. The region's burgeoning electronics and semiconductor industries are major contributors, with increasing demand for PVD in the fabrication of advanced microelectronic components and semiconductor devices. Moreover, the rapid expansion of solar energy projects, coupled with a focus on renewable energy sources, propels the demand for PVD in the production of efficient and durable solar panels. In addition, the automotive sector's growth and the emphasis on enhancing the performance and longevity of automotive components further fuel the adoption of PVD coatings.

The China physical vapor deposition market is estimated to grow at a significant CAGR over the forecast period. The rapid expansion of electric vehicles (EVs) and renewable energy is expected to significantly drive the PVD market in China. PVD is crucial in manufacturing advanced materials used in lithium-ion batteries and fuel cells, enhancing their performance, durability, and energy efficiency.

The physical vapor deposition market in India held a 10.6% market share of Asia Pacific in 2023. The increasing utilization of renewable energy resources is driving the demand for solar panels and fuel cells, which, in turn, is expected to drive the demand for thin film coatings. For instance, in May 2021, the Indian Renewable Energy Development Agency Limited invited bids from solar module companies to set up manufacturing units. This indicates a major push by the government toward domestic manufacturing, resulting in increased demand for PVD coating over the forecast period.

Europe Physical Vapor Deposition Market Trends

The physical vapor deposition market in Europe is anticipated to witness significant growth from 2024 to 2030. The European Union has recently approved a substantial state aid worth USD 8.69 billion, aimed at stimulating research & development activities related to chip design and manufacturing with a special emphasis on emerging technologies such as 5G and 6G communications, autonomous vehicles, artificial intelligence, and quantum computing. This move has significantly boosted the demand for PVD within the microelectronics industry. PVD is crucial for producing microelectronics, providing enhancements in durability, functionality, and the potential for device miniaturization.

The Germany physical vapor deposition market is expected to grow significantly at a CAGR 7.0%. As a prominent automotive manufacturing hub, Germany is at the forefront of developing vehicles and emission-reduction technologies. The rising adoption of PVD in automotive industry is expected to drive the market.

The physical vapor deposition market in the UK held a significant share of the Europe market in 2023, owing to the rising end-use industries. Rising investments in the semiconductor industry by the government of the UK for building local supply chains to modernize the automotive sector is anticipated to have a positive impact on the PVD market growth.

Central & South America Physical Vapor Deposition Market Trends

The physical vapor deposition market in Central & South America is estimated to grow rapidly in the coming years. Central & South America is witnessing an increase in healthcare expenditure, accompanied by advancements in medical technologies and devices. Biomedical or surgical devices are designed to improve the quality of life. These devices are required to be durable and biocompatible with low friction. PVD coatings offer all the features mentioned above for all materials commonly used in the development of biomedical devices.

The Brazil physical vapor deposition market is expected to grow significantly at a CAGR 7.6% from 2024 to 2030. The ongoing expansion of the consumer electronics industry and the increasing adoption of advanced technologies such as thermal evaporation, sputtering in Brazil are driving the demand for high-quality coatings to enhance the performance and lifespan of electronic devices.

Middle East & Africa Physical Vapor Deposition Market Trends

The physical vapor deposition market in Middle East & Africa is estimated to grow rapidly over the coming years. The semiconductor industry is one of the primary drivers of the PVD market in this region. Countries like Saudi Arabia and the UAE have been investing in semiconductor manufacturing, which leads to a rising demand for PVD for the production of advanced semiconductor devices. In March 2022, the King Abdulaziz City for Science and Technology (KACST) in Saudi Arabia unveiled the Saudi Semiconductor Program-the region's first-ever initiative of its kind.

The South Africa physical vapor deposition market is expected to grow significantly at a CAGR 7.4% from 2024 to 2030. In response to South Africa's energy crisis and the escalating demand for solar power, Anuva Green Energy (AGE), a tax-leveraged alternative investment firm, decided to establish strategic partnerships with leading solar energy companies. These alliances aim to tackle energy challenges and cater to the increasing need for solar solutions in the country. Therefore, the growth of the solar energy industry is expected to propel the demand for PVD market in South Africa.

Key Physical Vapor Deposition Company Insights

Some of the key players operating in the market include Oerlikon Group and IHI Corporation.

-

Oerlikon Group was established in 1946 and is headquartered in Pfäffikon SZ, Switzerland. The company manufactures and supplies PVD coating equipment. Products manufactured by the company suit many applications including batch & inline systems, mobile phones, laptop metallization, consumer goods, and notebook housing. ISO-9001 and ISO/TS 16949 certify its manufacturing facilities for its quality standards. As of 2022, the company had 182 locations across 37 countries.

-

IHI Corporation, formerly known as Ishikawajima-Harima Heavy Industries Co., Ltd., is a prominent Japanese industrial and engineering company. It has a long history dating back to its establishment in 1853. IHI has evolved into a comprehensive heavy industry manufacturer with a global presence, involved in various sectors.

Intevac, Inc.; Impact Coatings AB; and Denton Vacuum are some of the emerging participants in the market.

-

Intevac, Inc. was established in 1991 and is headquartered in California, U.S. The company operates its business through two segments, namely thin film equipment segment, which caters to hard disk drives; solar; display panels; and advanced packaging industries, and the photonics segment that serves military industry. It operates through its manufacturing facilities in California and Asia. Intevac performs direct product sales through its sales force; however, indirect sales are done through its distributors in Japan and China. The company’s sales in Asia are administered its offices in Malaysia, China, and Singapore.

-

Impact Coatings AB was established in 1997 and has headquarters in Linkoping, Sweden. The company primarily supplies PVD technology for end users in the automotive, fuel cells, and fashion industries. It has coating processes for plastics and metals and the products are marketed under the brand name MAXPHASE. The company’s PVD equipment is marketed under the brand name INLINECOATER. It operates mainly with two verticals called PVD Equipment and Coating Services. PVD Equipment has a product line called INLINECOATER, along with services such as maintenance and support. Whereas coating services vertical includes tailored coating solutions called Ceramic MAXPHASE, Silver MAXPHASE, and Ultra MAXPHASE.

Key Physical Vapor Deposition Companies:

The following are the leading companies in the physical vapor deposition market. These companies collectively hold the largest market share and dictate industry trends.

- Oerlikon Group

- Angstrom Engineering Inc.

- Kurt J. Lesker Company

- Voestalpine AG

- NISSIN ELECTRIC Co., Ltd

- IHI Corporation

- HEF Groupe

- Kobe Steel Ltd.

- Lafer S.p.A.

- Inorcoat

Recent Developments

-

In February 2024, Oerlikon Group’s brand for thin film surface solutions, BALINIT ALCRONA EVO, launched the third generation of its PVD coatings. These coatings have been significantly improved and offer over 30% longer service life than the previous version. Additionally, the enhanced wear resistance of BALINIT ALCRONA EVO decreases the amount of material removed during reconditioning, allowing for more regrinding cycles per tool.

-

In June 2022, Denton Vacuum LLC revealed its success in securing a new order for a semiconductor laser facet coating system from a prominent laser manufacturer. The Infinity Biased Target Sputtering system, incorporating Denton's patented bias target technology, stands out for its ability to deliver exceptionally dense and low-contamination optical films. This technology, surpassing other Physical Vapor Deposition methods, ensures optimal laser damage threshold performance.

Physical Vapor Deposition Market Report Scope

|

Report Attribute |

Details |

|

Market size value in 2024 |

USD 3.2 billion |

|

Revenue forecast in 2030 |

USD 5.0 billion |

|

Growth rate |

CAGR of 7.6% from 2024 to 2030 |

|

Base year for estimation |

2023 |

|

Historical data |

2018 - 2023 |

|

Forecast period |

2024 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2024 to 2030 |

|

Report coverage |

Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

|

Segments covered |

Product, application, region |

|

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

|

Country scope |

U.S.; Canada; Mexico; Germany; UK; France; Italy; China; India; Japan; Australia; Brazil; Argentina; South Africa; UAE |

|

Key companies profiled |

Oerlikon Group; Angstrom Engineering Inc.; Kurt J. Lesker Company; Voestalpine AG; NISSIN ELECTRIC Co., Ltd; IHI Corporation; HEF Groupe; Kobe Steel Ltd.; Lafer S.p.A.; Inorcoat |

|

Customization scope |

Free report customization (equivalent up to 8 analysts working days) with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

Global Physical Vapor Deposition Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global physical vapor deposition market report based on product, application, and region:

-

Product Outlook (Revenue, USD Million, 2018 - 2030)

-

Thermal Evaporation

-

Sputter Deposition

-

Arc Vapor Deposition

-

-

Application Outlook (Revenue, USD Million, 2018 - 2030)

-

Semiconductor & Electronics

-

Solar Products

-

Cutting Tools

-

Medical Equipment

-

Other

-

-

Regional Outlook (Revenue, USD Million, 2018 - 2030)

-

North America

-

U.S.

-

Canada

-

Mexico

-

-

Europe

-

UK

-

Germany

-

France

-

Italy

-

-

Asia Pacific

-

China

-

Japan

-

Australia

-

India

-

-

Central & South America

-

Brazil

-

Argentina

-

-

Middle East & Africa

-

South Africa

-

UAE

-

-

Frequently Asked Questions About This Report

b. The global physical vapor deposition market size was estimated at USD 3.0 billion in 2023 and is expected to be USD 3.2 billion in 2024.

b. The global physical vapor deposition market, in terms of revenue, is expected to grow at a compound annual growth rate of 7.6% from 2024 to 2030 to reach USD 5.0 billion by 2030.

b. Asia Pacific region dominated the market and accounted for 43.1% share in 2023. The region's burgeoning electronics and semiconductor industries are major contributors, with increasing demand for PVD in the fabrication of advanced microelectronic components and semiconductor devices. Moreover, the rapid expansion of solar energy projects, coupled with a focus on renewable energy sources, propels the demand for PVD in the production of efficient and durable solar panels.

b. Some of the key players operating in the physical vapor deposition market include Oerlikon Group, Angstrom Engineering Inc., Kurt J. Lesker Company, Voestalpine AG, NISSIN ELECTRIC Co., Ltd, IHI Corporation, HEF Groupe, Kobe Steel Ltd., Lafer S.p.A., Inorcoat, KOLZER SRL, Advanced Coating Service, Impact Coatings AB, Denton Vacuum, Intevac, Inc.

b. The ever-expanding semiconductor industry, with its continuous demand for advanced thin-film deposition techniques, acts as a primary growth catalyst. Additionally, the rise in medical device manufacturing, driven by the need for enhanced durability and biocompatibility, contributes significantly to the market's upward trajectory.

We are committed towards customer satisfaction, and quality service.

"The quality of research they have done for us has been excellent."